How much does an Anaerobic Digester built for manure and nutrient management cost to construct, commission and run? That's the vital question for AD utilisation for manure management projects on farms.

If the sum of these costs is known and the price payable for the valuable outputs in energy and biofertiliser available to any farm business, they will be able to work out the ROI. How long before an AD plant investment will be likely to pay back, is the crucial question we try to answer here.

Sustainable farming practices are becoming essential in today’s agricultural landscape, and one increasingly popular method of waste management and renewable energy production is using anaerobic digesters.

These systems play a crucial role in manure management, turning organic waste into biogas and digestate, which can be used as fertilizer. However, one of the key considerations for farmers interested in installing these systems is anaerobic digester cost. This article explores the costs involved in implementing anaerobic digesters on farms for manure management and the potential benefits they bring.

What is an Anaerobic Digester?

An anaerobic digester is a system that breaks down organic matter—such as manure—in an oxygen-free environment. This process produces biogas, primarily composed of methane, which can be used for energy, and digestate, a nutrient-rich byproduct that can be applied to fields as a fertilizer. The system is highly effective in reducing greenhouse gas emissions, improving soil health, and providing renewable energy.

The Benefits of Anaerobic Digesters for Manure Management

Farmers with livestock face the challenge of managing large quantities of manure, which, if not properly handled, can lead to environmental pollution and odour problems with hard-to-estimate, but nevertheless very real costs.

Anaerobic digesters address these issues by turning waste into valuable resources:

- Biogas Production: Farmers can capture methane from the manure and use it to generate heat, electricity, or both. This reduces reliance on external energy sources, and in some cases, excess energy can be sold back to the grid.

- Odour and Pathogen Reduction: The digestion process significantly reduces manure odour and kills harmful pathogens, making it safer and less disruptive to the farm and surrounding areas.

- Nutrient-Rich Digestate: The byproduct of the process, digestate, is a valuable fertilizer rich in nitrogen, phosphorus, and other key nutrients. It can improve soil health while reducing the need for chemical fertilizers.

This sounds good, but for any business affordability is essential. The balance between ROI and cost must be positive. So what does an Anaerobic Digester Cost?

The Cost of Anaerobic Digesters

While the benefits of anaerobic digesters are clear, the upfront costs can be significant, especially for smaller farms. Understanding the cost components can help farmers evaluate the investment:

- Capital Costs

- The initial setup costs vary widely, depending on the size and complexity of the system. For a typical farm-based system, initial costs can range from $500,000 to over $1 million. Larger operations with more sophisticated technology can see costs climb higher.

- Equipment: This includes the digester tank, biogas handling system, gas storage, and generators for energy conversion. The type and size of the digester also impact the cost, with continuous systems tending to be more expensive than batch digesters.

- Construction: Installation costs include the construction of the facility, plumbing, and electrical work. These costs depend on the scale of the project, local labor rates, and specific regulatory requirements.

- Operating and Maintenance Costs

- Ongoing expenses, such as maintenance, repairs, and labor, add to the total cost of operating an anaerobic digester. These typically range from $20,000 to $50,000 annually, depending on the system size and complexity.

- Digesters require regular monitoring to ensure the system runs efficiently. Farmers often need to hire trained personnel to oversee the system or partner with service providers for ongoing maintenance.

- Permitting and Regulatory Costs

- Depending on the region, farmers may need to obtain permits for waste management, air emissions, and energy production. The cost of permits and environmental assessments can vary but typically adds a few thousand dollars to the project budget.

- Subsidies and Grants

- Fortunately, many government and environmental agencies offer subsidies, grants, and low-interest loans to farmers looking to invest in anaerobic digesters. For example, the U.S. Department of Agriculture (USDA) provides financial assistance through programs like the Rural Energy for America Program (REAP). Farmers can recoup a significant portion of their initial investment through these programs, lowering the financial barrier.

- Additionally, revenue from selling Renewable Energy Credits (RECs) or carbon offsets can create an extra income stream, further reducing the net cost.

The Return on Investment (ROI)

Although the upfront cost of anaerobic digesters may seem high, the long-term savings and revenue generation make them a sound investment for many farms. Energy savings from using biogas can significantly reduce operational costs, while selling excess power to the grid can generate steady income.

Farmers can also cut down on fertilizer expenses by using digestate as a nutrient-rich alternative.

In some cases, farms have achieved a ROI within five to ten years, depending on the scale of the system, energy prices, and available subsidies. Large-scale farms tend to see quicker payback periods due to the higher volume of manure available for digestion and the resulting energy output.

Key Considerations Before Installing a Digester

- Farm Size and Manure Volume: Anaerobic digesters are most effective for farms with large numbers of livestock, where manure production is high enough to sustain energy generation. Small farms may struggle to justify the investment unless they form a co-op with nearby farms to share costs and benefits.

- Regulatory Requirements: Farmers should consult local and state environmental agencies to ensure compliance with regulations governing waste management, air emissions, and energy production.

- Energy Needs: It's essential to evaluate the farm’s current and future energy needs to determine the best size and type of anaerobic digester. Farmers should also consider the potential to sell excess energy back to the grid, where regulations permit.

- Technical Expertise: Operating an anaerobic digester requires knowledge of the biological and technical processes involved. Farmers will need to either train personnel or contract out the maintenance and management of the system.

Anaerobic Digester Cost – Conclusion

While the cost of installing an anaerobic digester for manure management can be substantial, the potential benefits in terms of waste reduction, energy generation, and environmental sustainability make it a compelling option for many farms.

Those very significant anaerobic digester costs can be paid back handsomely with the right planning, financial assistance, and technical support. When this works, anaerobic digesters can offer a pathway to a more sustainable, energy-efficient future for many livestock operations.

Farmers looking to reduce their environmental footprint, improve manure management, and generate additional revenue streams should consider the long-term value of investing in anaerobic digesters.

When we published the first edition of this page back in 2013 we said:

- For the right farm business or operator of any process which produces as a by-product a consistent organic waste, an anaerobic digester producing biogas coupled to a generator can be an excellent long-term investment;

but, subsequently, the cost of solar and wind turbine-based energy has fallen and it makes no sense to compete with these other cheaper (admittedly not reliable 24/7) options. Now, in 2021 we say:

- Add a system to upgrade the quality of the biogas and produce biomethane and you will gain both a huge market to sell your energy into, and a market for transport fuel especially, which is growing more rapidly than new AD capacity can ever hope to match.

We offer an anaerobic digestion plant feasibility study consultancy service, and for UK agricultural businesses it may be possible to claim back 30% or more of the cost of such a study.

Contact us here by completing our email form, for more information.

The following is our article as first published in December 2013. It remains relevant as it concentrates on providing sources of Anaerobic Digester Cost data and Calculators:

Anaerobic Digester Cost Data and Calculators (2013)

The best examples of implementing an anaerobic digester can mean a facility pays nothing for fuel. Facilities that need to replace a life-expired electric generator set should consider all options, and include a biogas digester model within their energy options. The decision should ultimately be based on what works best for a particular site and operator when the balance between investment risk incurred by adopting an Anaerobic Digestion process, against the benefits.

But, unfortunately, finding anaerobic digestion cost data to help put a price on the power over a set payback period is as hard as ever.

Looking to Government Bodies Who Provide Information on their view on Anaerobic Digestion costs, does not lead to in-depth analysis. We concentrated on finding costs for so-called “manure management” biogas plants, and we found the following statements:

Cost estimates for installing anaerobic digester systems [given here] have been based on manure-fed on-farm digesters. The estimated cost for a digester alone is between $400 and $700 per 1000 pounds of livestock weight to install. For dairy farms producing electricity, the installed cost is estimated at $800 to $1200 per cow for anaerobic digester system installation. The engine-generator can be up to half the cost of the project. Besides installation, it is important to consider insurance, operation and maintenance costs. Annual operation and maintenance costs can range from $11,000 for a small digester to $51,000 for a large system.

The U.S. E.P.A.’s AgSTAR program has advised that anaerobic digester installation may not be economical for farms with less than 500 animal units (an animal unit is defined as 1000 pounds live weight), based on energy payback and using solids for bedding or selling as a soil amendment. If generating electricity, the electricity purchase price will have a large influence on the payback rate. Most systems can not be justified on producing electricity alone. Avoided costs of using digested solids as bedding and off setting some heating costs are usually necessary to justify the investment. As anaerobic digester technology continues to improve, it may become more feasible to install anaerobic digester systems on smaller farms.

An anaerobic digester system does not run itself, it is not self-maintaining. [There are additional costs.] The system requires continuous monitoring, which is often done using computer-operated sensors. An anaerobic digester system requires temperature and pH regulation, as well as feedstock consistency. It will usually require 30 minutes to an hour per day to make adjustments and perform maintenance. Most systems that have failed were in part because of a lack of oversight and a person to champion the system.

www.scotland.gov.uk/Resource/Doc/1057/…

Agstar themselves say the following about Anaerobic Digester Cost:

The profitability of a biogas digester depends on the size of the operation, the method of manure management and local energy costs. According to AgSTAR, biogas recovery can be profitable and most effective at existing operations of at least 500 cows or 2,000 swine. Manure should be collected frequently (at least once a week) in a liquid, slurry or semi-solid state. Any electricity that is not used on-site can usually be sold to the local utility.

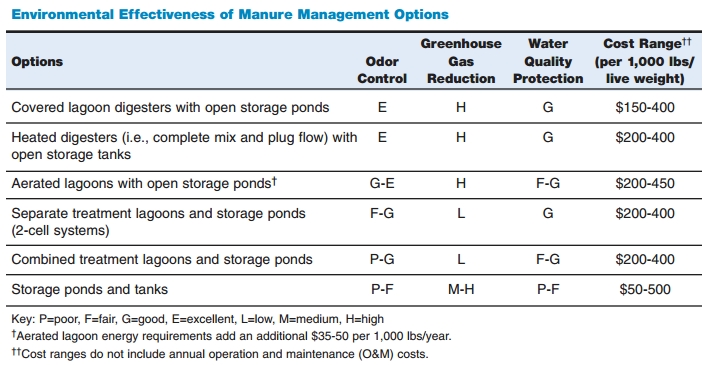

and Agstar also provides the following table of manure management anaerobic digestion costs (2020 prices):

In addition to the above, we have found some examples of press releases that provide at least some indication of the cost of their Anaerobic Digestion Plants and may be worth reading in full to find information about individual biogas project/Anaerobic Digester costs.

The small city of Junction City is home to Oregon's first anaerobic digester, at the family-owned and run Lochmead Farms. Although not an incredibly new technology, Lochmead Farms, a dairy producer, is truly a frontrunner in green dairy technology in Oregon. The digester captures methane gas from cow manure and burns it in a turbine to create power. The anaerobic digester cost $2.2 million and was built by Revolution Energy Solutions of Washington, D.C.

The digester creates 1.5 million kilowatt-hours of electricity, enough to power 300 homes each year. So much energy is produced that there is enough to sell some to a local public utility. The dairy farm itself, which was founded in 1941, has been at the cutting edge in alternative energy sources as well as local food and vertical business integration. The farm is building solar panels and produces 80 percent of the hay for its dairy cows.

[Link not found: www.mass.gov]

On 26th August 2013, the second biogas plant at the Viessmann Company’s headquarters in Allendorf (Eder) was inaugurated. The first biogas plant went into operation three years ago.

The new wet fermentation plant built by its subsidiary, Schmack Biogas, cost around €7 million. The biogas plant produces 1.5 million cubic metres of biogas annually, enough to provide about 1,650 households with electricity and 370 households with heat.

http://books.google.com/books?… …biogas+cost?

This article has so far admittedly, not yet provided an abundance of data on the cost of biogas digesters for manure management.

This article has so far admittedly, not yet provided an abundance of data on the cost of biogas digesters for manure management.

We thought this while writing and tried searching for an “anaerobic digester calculator” by using the Google search engine, and while wondering whether our readers might be able to calculate their costs that way we discovered that such calculators do exist.

First, we found an interactive Excel spreadsheet calculator. This one is an alternative method for assessing the viability of an on-farm biogas digester and is available to members of the National Non-Food Crops Centre (NNFC} which you can join for a charge. There are two membership levels. Non-members can also buy this but at an increased price.

Follow the following link below for more information: www.nnfcc.co.uk

Other biogas digester cost calculators are also available at:

http://biorealis.com/wwwroot/digester_revised.html and http://www.esru.strath.ac.uk/EandE/Web_sites/03-04/biomass/calculator.html

End of Article first published December 2013. Updated June 2021 and September 2024.]

Exceptional article. This Anaerobic Digester Cost – Manure Management Projects On-Farm page is just what I wanted to find. Thanks.

Excellent article. We think. Over time, the organic waste is broken down in the digester by the microorganisms. This breakdown process involves the microorganisms emitting methane gas and carbon dioxide. Thank you!

Farmers can calculate the viability of future anaerobic digestion projects by using the latest edition of the AD cost calculator from the National Non Food Crops Centre.