Using Dairy Digesters to Increase Farm Income with These Biogas Plant Integration Tips.

Notable Points:

- Biogas digesters can transform dairy farm waste into multiple revenue streams while reducing environmental impact and operational costs.

- A 500-cow dairy operation can potentially generate enough electricity to power 50-100 homes through biogas production.

- Beyond energy production, farmers can earn income from carbon credits, premium fertilizer sales, and tipping fees from food waste partnerships.

- Strategic planning of digester size and integration with existing farm systems is crucial for maximizing return on investment.

- US Government grants and incentives (January 2025) can offset up to 50% of initial digester costs, dramatically improving project viability.

The sustainable revolution in dairy farming isn't just about environmental responsibility—it's about creating new income sources in an industry with notoriously tight margins. Anaerobic digesters are transforming how dairy operations manage waste while simultaneously generating significant revenue through biogas production.

By integrating these systems, forward-thinking farmers are turning what was once a disposal challenge into a valuable farm asset. Sustainable biogas integration represents one of the most promising developments in modern dairy farm management, offering environmental benefits alongside real financial returns.

Transform Manure into Money: How Biogas Digesters Create New Income

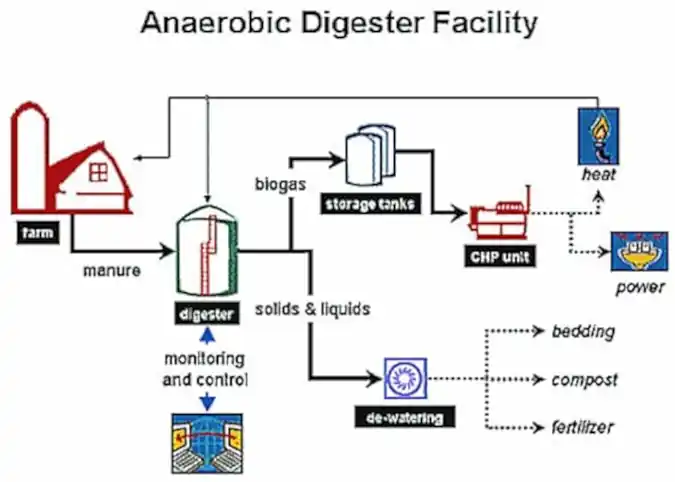

Biogas digesters function as powerful waste-to-wealth converters on dairy farms, capturing methane that would otherwise contribute to greenhouse gas emissions and transforming it into valuable energy products.

The biological process is elegantly simple: bacteria break down organic waste in oxygen-free environments, producing a methane-rich biogas that can be harnessed for multiple applications. This transformation addresses two critical challenges simultaneously—waste management and energy production—while creating multiple revenue streams for farm operations.

The financial impact can be substantial. A properly sized and managed digester system can reduce on-farm energy costs by 50-100%, depending on herd size and energy needs.

Some operations generate excess energy that can be sold back to the grid, creating ongoing passive income.

The investment, while significant, typically shows positive returns within 5-7 years when all benefits—including reduced fertilizer costs, waste management savings, and energy production—are calculated together.

“Anaerobic Digesters – Cornell Small Farms” from smallfarms.cornell.edu and used with no modifications.

What Makes Dairy Farms Perfect for Biogas Production

Dairy operations possess unique characteristics that make them ideal candidates for biogas production systems. The consistent, daily production of manure creates a reliable feedstock supply that ensures steady biogas output—a crucial factor that many other potential biogas applications lack.

With each lactating cow producing approximately 80 to 150 pounds of manure daily, even modest-sized dairy operations generate substantial organic material that can fuel digester systems year-round.

The composition of dairy manure itself offers advantages for anaerobic digestion. The nutrient balance, moisture content, and biological activity in fresh dairy waste create nearly ideal conditions for the microorganisms responsible for biogas production.

This natural compatibility means dairy farmers can often implement simpler digester systems compared to operations that must pre-process their feedstock materials.

Consistent Manure Supply Creates Reliable Energy Source

The daily rhythm of dairy operations translates directly into consistent biogas production potential. With regular milking schedules and housing systems that facilitate manure collection, dairy farms maintain the steady feedstock supply that biogas systems require for optimal performance. Unlike seasonal agricultural operations that may experience significant fluctuations in biomass availability, dairy farms produce manure continuously throughout the year.

This reliability translates directly into predictable energy generation. A depending on the data source used, a 500-cow dairy operation typically produces enough manure to generate approximately 600,000 to 800,000 cubic feet of biogas monthly—equivalent to roughly 350 to 500 megawatt-hours of electricity annually when converted through generator systems. This output can power farm operations while potentially supplying electricity for 100-150 typical American homes.

The consistency factor extends beyond just quantity—dairy manure quality remains relatively stable throughout the year compared to other feedstocks, maintaining a predictable methane production potential that allows for more precise system design and operational planning. This predictability reduces investment risk and improves financial forecasting for biogas projects.

“Dairy Digester Spawns Multiple …” from www.biocycle.net and used with no modifications.

Dairy Farm Biogas Production Potential

Herd Size: 500 milking cows

Daily Manure Production: 75,000 lbs (37.5 tons)

Monthly Biogas Production: ~800,000 cubic feet

Annual Electricity Generation: ~500 MWh

Homes Powered Equivalent: 50-100 average households

Carbon Offset: ~3,500 metric tons CO₂ equivalent annually –

Assumes high yielding plains grassland and 60% methane content

On-Farm Energy Needs That Digesters Can Fulfill

Dairy operations have substantial energy requirements that align perfectly with biogas production capabilities. Milk cooling, water heating, ventilation, and lighting systems collectively consume significant electricity—often between 800-1,200 kWh per cow annually. Biogas systems can directly offset these costs through on-site electricity generation or combined heat and power (CHP) systems that produce both electricity and thermal energy.

The heating demands of dairy operations are particularly well-suited to biogas utilization. Water heating for equipment sanitation, space heating in cold climates, and even milk pasteurization can all be powered using the thermal energy captured from biogas combustion. This thermal recovery component significantly improves overall system efficiency, often capturing 60-70% of the biogas energy that would otherwise be lost during electricity generation alone.

Seasonal energy needs, such as increased ventilation during summer months or heating during winter, can also be addressed through properly designed biogas systems with adequate biogas storage capacity. This flexibility allows dairy operators to match energy production with consumption patterns throughout the year, maximizing the economic value of their biogas resources.

5 Revenue Streams from Your Biogas Plant

The financial power of biogas systems comes from their ability to generate multiple income sources simultaneously. Unlike single-purpose farm investments, digesters create diverse revenue opportunities that collectively build a compelling business case. Understanding these potential income streams is essential for proper system planning and maximizing return on investment.

1. Electricity Generation and Grid Sales

Converting biogas to electricity using generator sets represents the most straightforward path to monetizing biogas production. Modern biogas generators achieve conversion efficiencies of 30-40%, producing approximately 2 kilowatt-hours of electricity per cubic meter of biogas. For large dairy operations, this can translate into substantial power generation that exceeds on-farm needs.

Excess electricity can be sold to utilities through various mechanisms, including net metering programs, feed-in tariffs, or power purchase agreements (PPAs). Payment rates vary significantly by region, ranging from $0.04 to $0.15+ per kWh, with renewable energy premiums available in many markets. Long-term PPAs with fixed rates provide revenue stability that significantly enhances project financing options.

2. Renewable Natural Gas Production

Upgrading biogas to renewable natural gas (RNG) represents an increasingly attractive option as natural gas infrastructure and renewable fuel incentives expand. This process removes carbon dioxide, hydrogen sulfide, moisture and other impurities from biogas to create pipeline-quality methane that can be injected into natural gas distribution systems or used as vehicle fuel. For more insights, check out this Farmer's Guide to Biogas.

The economic value of RNG often exceeds electricity generation, particularly when transportation fuel credits are available. Under programs like California's Low Carbon Fuel Standard or the federal Renewable Fuel Standard, RNG used for transportation can generate credits worth $5-30 per million BTU above the base fuel value.

These premium payments have transformed the economics of dairy biogas projects in recent years, driving significant investment in RNG upgrading systems.

3. Carbon Credit Markets

Methane capture from manure management qualifies for carbon offset credits in various markets, creating additional revenue opportunities beyond energy production. By preventing the release of methane (a greenhouse gas 25-28 times more potent than CO₂), dairy digesters generate quantifiable emissions reductions that can be sold as carbon credits.

Voluntary carbon markets typically value these credits at $5-15 per metric ton of CO₂ equivalent, while compliance markets like California's cap-and-trade system have historically traded at $15-30 per ton. For a 1,000-cow dairy operation, this can represent $30,000-100,000 in annual carbon credit revenue, depending on baseline emissions and market conditions.

As carbon markets mature and expand, these values are expected to increase, enhancing project economics.

4. Digestate as Premium Fertilizer

The nutrient-rich liquid and solid residues from the digestion process—collectively called digestate—offer significant value as organic fertilizers. The anaerobic digestion process converts organic nitrogen into more plant-available ammonium forms while preserving virtually all the original nutrients from the manure feedstock. This transformation creates a more effective fertilizer product compared to raw manure.

Beyond on-farm use, processed digestate can be marketed to other agricultural operations, landscapers, or garden centers. Liquid digestate fractions can be applied using precision irrigation systems, while separated solids can be composted, pelletized, or bagged for retail sale.

Some dairy operations report additional revenue of $50-100 per cow annually through strategic marketing of digestate products.

5. Tipping Fees from Food Waste Partnerships

Many dairy digesters can accept off-farm organic materials as supplemental feedstock, creating opportunities to charge tipping fees for waste disposal services. Food processing byproducts, restaurant waste, expired grocery items, and similar materials often have high biogas production potential while generating disposal fees of $20-60 per ton.

Co-digestion with these high-energy materials can increase biogas production by 30-300% compared to manure alone, while simultaneously creating a valuable community service.

Developing relationships with food processors or waste management companies can establish steady feedstock supplies and tipping fee income that significantly enhance project economics.

Planning Your Biogas System: Size and Scale Considerations

Proper sizing of your biogas system is critical to ensure optimal performance and financial returns. Undersized systems leave potential energy production untapped, while oversized installations create unnecessary capital expenses and operational challenges. The ideal digester capacity should align with your farm's current manure production while allowing for reasonable expansion over the system's lifespan.

Most digesters are designed with hydraulic retention times (HRT) of 20-30 days, meaning the volume should accommodate approximately one month's worth of manure production plus any co-digestion materials. For planning purposes, each lactating cow produces roughly 150 pounds (18 gallons) of manure daily, translating to about 550 gallons monthly per animal. This baseline calculation provides the foundation for determining appropriate digester volume.

Matching Digester Capacity to Your Herd Size

Herd size serves as the primary determinant of digester capacity, with commercial systems typically becoming economically viable at 200+ cow operations. A 500-cow dairy typically requires a digester volume of approximately 300,000 gallons to properly process manure with adequate retention time. This sizing ensures that organic material remains in the digester long enough for maximum biogas extraction while maintaining system stability.

When evaluating capacity requirements, consider not just current herd size but anticipated growth over the next decade. Modular digester designs can offer expansion flexibility, allowing capacity to grow incrementally with your operation. Some systems can also be initially oversized with the intention of accepting food waste or other off-farm organics to utilize full capacity until herd expansion occurs.

The energy output potential should be calculated based on realistic biogas yields and conversion efficiencies. Well-managed dairy manure typically produces 80-120 cubic feet of biogas per cow daily, with methane content around 60%. This translates to approximately 3-4 kWh of electricity potential per cow daily when converted through generator systems operating at 35% efficiency.

Space Requirements and Farm Layout Integration

Physical space considerations extend beyond just the digester vessel itself to include supporting infrastructure, maintenance access, and safety buffers. A complete digester system for a mid-sized dairy typically requires 1-2 acres of land when including all components—digester vessels, gas handling equipment, generators or upgrading systems, and digestate storage.

Proximity to both manure collection points and energy utilization infrastructure significantly impacts system efficiency and operational costs. Ideally, digesters should be positioned to minimize pumping distances from barn collection systems while maintaining appropriate setbacks from residential areas (typically 300+ feet). Consider future farm development plans to ensure digester placement doesn't conflict with potential expansion areas.

Financial Roadmap: From Investment to Profit

The investment profile for dairy digesters varies significantly based on scale, complexity, and chosen technologies. Complete systems typically cost between $3,000-5,000 per cow, translating to approximately $1.5-2.5 million for a 500-cow operation. This substantial investment requires careful financial planning and often benefits from external funding sources to achieve acceptable returns.

The total project cost encompasses several major components: the digester vessel and containment systems (30-40% of total cost), biogas collection and conditioning equipment (15-20%), energy conversion systems like generators or upgrading equipment (20-30%), and engineering/permitting costs (10-15%). Additional expenses include site preparation, utility interconnection, and digestate handling infrastructure.

Initial Costs: What to Budget For

Beyond the obvious equipment costs, comprehensive budgeting must account for site preparation, permitting fees, utility interconnection studies, and project management expenses.

Many farmers are surprised by the costs associated with regulatory compliance, which can add $50,000-150,000 to project expenses depending on location and system complexity. Professional engineering services typically add another 7-12% to total project costs but are essential for system optimization and trouble-free operation.

Grid interconnection costs can vary dramatically based on local utility requirements and existing infrastructure. Basic electrical connections may cost $50,000-100,000, but requirements for specialized transformers, line upgrades, or advanced monitoring equipment can push these expenses much higher. Early engagement with utility providers helps identify potential cost concerns before committing to specific system designs.

Payback Period Expectations

Realistic financial planning typically shows payback periods of 5-8 years for well-designed systems with multiple revenue streams. Projects focused solely on electricity generation generally fall at the longer end of this range, while those incorporating RNG production, carbon credits, and tipping fees may achieve payback in as little as 4-5 years under favorable regulatory conditions.

Cash flow projections should account for all revenue sources while incorporating realistic operational costs.

Annual operation and maintenance expenses typically run 3-5% of capital costs, including routine maintenance, occasional repairs, system monitoring, and operational labor (typically 1-2 hours daily) per digester tank. Proper accounting for these ongoing expenses is essential for accurate financial forecasting.

Grants and Incentives That Cut Your Costs

Government programs substantially improve project economics through grants, tax incentives, and guaranteed payment programs. The USDA's Rural Energy for America Program (REAP) offers grants covering up to 25% of project costs and loan guarantees for an additional 75%.

State-level programs often provide complementary funding, with some states offering investment tax credits, sales tax exemptions, or property tax reductions for renewable energy systems.

The federal Investment Tax Credit (ITC) allows qualifying biogas projects to recover 30% of eligible capital costs through tax credits, significantly improving project economics for taxpaying entities.

Accelerated depreciation provisions further enhance returns by allowing most system components to be depreciated over a 5-year schedule rather than the typical 20+ year useful life, creating valuable early-year tax benefits.

Working with Investors vs. Full Ownership

Various ownership models exist to match different risk profiles and capital availability situations. Full ownership provides maximum control and long-term benefit but requires substantial capital and management commitment. T

hird-party ownership models, where developers build and operate systems on your property, minimize upfront costs and operational responsibilities but typically capture 60-80% of project revenues.

Hybrid approaches like joint ventures or lease-to-own arrangements can balance risk and reward while leveraging external expertise. Under these models, farmers typically provide feedstock guarantees and land access while partners provide capital and technical expertise, with revenue sharing negotiated based on respective contributions.

These partnerships often include options for farmers to increase ownership percentages over time as project risks decrease.

Technical Integration: Making Your Digester Work With Existing Systems

Successful digester projects require thoughtful integration with existing farm infrastructure to minimize disruption while maximizing efficiency. The manure collection system serves as the critical starting point, often requiring modifications to ensure consistent feedstock delivery to the digester. Sand bedding, excess water from parlor washdown, and certain chemicals can all impact digester performance and may necessitate pre-treatment processes.

Manure Collection System Modifications

Most digesters perform optimally with consistent manure solids content of 8-12%, which may require adjustments to water usage in flush systems or installation of solids separation equipment. Farms using sand bedding typically need sand separation systems upstream of digesters to prevent accumulation within vessels. These modifications add cost but protect long-term system performance and prevent expensive maintenance issues.

The timing and frequency of manure transfer to digester systems impact both operational efficiency and biogas production stability. Continuous or frequent feeding (multiple times daily) generally produces more consistent gas output compared to batch loading. Automated pumping systems with programmable controls optimize this process while minimizing labor requirements, though they represent additional capital investment.

Existing storage structures can often be repurposed within the digester system, potentially reducing project costs. Pre-digestion mixing tanks might utilize existing reception pits, while post-digestion storage could incorporate existing lagoons after appropriate modifications. These integrations should be carefully evaluated by design engineers to ensure compatibility with new process requirements.

If food waste is accepted plastic and other packaging and inert material such as grit must be removed using depackaging and separation equipment before the organic content is fed into the digester tank.

Energy Distribution Infrastructure

Connecting your biogas system to existing energy infrastructure requires careful planning and often specialized equipment. For electricity generation, synchronization equipment ensures generator output matches grid parameters for seamless integration. Thermal recovery systems can be connected to existing heating loops, but often require heat exchangers and controls to prioritize thermal loads appropriately.

Renewable natural gas projects require more extensive infrastructure, including gas cleaning systems, compression equipment, and potentially miles of pipeline to reach injection points. These projects typically involve partnerships with natural gas utilities and require detailed engineering to meet stringent gas quality specifications. The higher complexity translates to greater capital costs but often delivers superior financial returns in markets with strong RNG incentives.

Monitoring and Control Systems

Modern digesters incorporate sophisticated monitoring systems that track biological health indicators, gas production, and equipment performance. These systems serve both operational and compliance purposes, allowing operators to identify potential issues before they affect performance. Key monitoring points include biogas production rate, methane content, digester temperature, pH levels, and volatile fatty acid concentrations.

Remote monitoring capabilities have become standard features, allowing operators to receive alerts and make adjustments via smartphone apps or web interfaces. These systems dramatically reduce labor requirements while improving response times to potential issues. The data collected also supports compliance reporting for environmental permits and verification of carbon credits or renewable energy attributes.

Real Farmer Results: Success Stories and Lessons Learned

The Goodrich Family Dairy in Vermont installed a 600,000-gallon digester for their 900-cow operation in 2014, generating electricity through a 300kW generator while utilizing recovered heat for barn warming and milk processing. The project achieved payback within 6 years despite initial challenges with feedstock consistency. Their key lesson: invest in proper training for farm staff to ensure consistent digester operation.

Similarly, Holsum Dairies in Wisconsin implemented a two-stage digester system that processes manure from 8,000 cows while accepting food processing waste from nearby facilities. Their tipping fee revenue exceeds $400,000 annually, dramatically improving project economics while diverting organic waste from landfills. For more on farm equipment and system solutions, visit anaerobic digester farm equipment system solutions.

Your First Steps to Biogas Integration

Begin your biogas journey with a comprehensive feasibility assessment that evaluates your specific operation's potential. Contact your state's agricultural extension service or the AgSTAR program (EPA) for educational resources and potential funding sources.

Arrange visits to operational digester systems of similar scale to learn directly from other farmers' experiences. When evaluating proposals from technology providers, insist on references from similar-sized installations and validate performance claims through independent engineers.

Remember that successful projects require commitment to proper operation and maintenance—the best equipment will underperform without consistent management attention.

Frequently Asked Questions

As you explore biogas integration for your dairy operation, you'll likely encounter common questions about these systems. The following answers address the most frequent concerns farmers raise during the planning process, providing practical insights to inform your decision-making.

Remember that while these general answers offer guidance, consulting with qualified engineers and financial advisors familiar with your specific operation is essential for accurate planning.

How much does a dairy farm biogas digester typically cost?

Complete digester systems typically cost $3,000-5,000 per cow, with economies of scale favoring larger installations. A 500-cow dairy might invest $1.5-2.5 million for a complete system including digester vessel, gas handling equipment, generators or upgrading systems, and necessary site improvements.

Simpler covered lagoon systems may cost less ($1,500-2,500 per cow) but typically produce less biogas per unit of manure. More complex systems with advanced gas upgrading capabilities for renewable natural gas production can exceed $6,000 per cow but often generate superior financial returns in markets with favorable incentives.

Can small farms (under 200 cows) benefit from biogas systems?

Small-scale operations face economic challenges with conventional digester systems due to the high fixed costs for engineering, permitting, and specialized equipment. These fixed expenses represent a much larger percentage of total project costs for smaller farms, extending payback periods beyond practical timeframes. For more information on suitable anaerobic digester farm equipment solutions, explore further resources.

However, emerging simplified designs specifically targeting smaller operations show promise. Modular, pre-fabricated systems can reduce engineering and installation costs, while collective models where multiple farms share centralized processing facilities help achieve necessary economies of scale.

Small operations should also investigate simpler technologies like covered lagoons with passive gas collection, which offer lower methane capture efficiency but substantially reduced capital costs.

What maintenance is required for a biogas digester?

Preventative maintenance represents the critical difference between profitable, long-running systems and problematic installations. Daily tasks include monitoring key parameters (temperature, gas production, pH levels), inspecting critical components, and addressing minor issues before they escalate.

Weekly maintenance typically involves checking and lubricating pumps and mixers, while monthly procedures include calibrating monitoring equipment and inspecting gas handling systems.

Major maintenance events like generator overhauls occur at manufacturer-specified intervals (typically 8,000-10,000 operating hours) and represent significant expenses that must be budgeted for in advance. For more insights on system solutions, check out this resource on anaerobic digester farm equipment.

How do seasonal temperature changes affect biogas production?

Seasonal temperature fluctuations primarily impact unheated digester systems, with production potentially dropping 30-50% during winter months in northern climates. Properly designed heated digesters maintain stable internal temperatures year-round (typically 95-105°F for mesophilic systems), ensuring consistent biological activity and gas production regardless of ambient conditions.

Heating requirements increase during colder months, consuming more of the biogas energy for process maintenance, which can reduce net energy available for other uses. To understand the broader context of biogas as a renewable energy source, you can explore more about biogas for electricity and its technology challenges.

System designs for cold climates typically incorporate additional insulation, more robust heating systems, and sometimes seasonal adjustments to feeding rates to maintain optimal performance. Underground or partially buried digesters benefit from soil's natural insulating properties, reducing heating requirements compared to above-ground installations.

What permits are needed to install and operate a biogas system?

Permitting requirements vary significantly by location but typically include construction permits, environmental permits, and utility interconnection agreements. Most operations require air quality permits addressing potential emissions from generators or flares, water quality permits for digestate handling, and local building/zoning approvals. Environmental reviews may trigger additional requirements if projects are near sensitive areas or exceed certain size thresholds.

The permitting process often represents one of the longest project development phases, typically requiring 6-18 months depending on jurisdiction complexity. Early engagement with regulatory authorities helps identify potential concerns and streamlines the approval process. Many successful projects benefit from consultants specializing in renewable energy permitting who understand the specific requirements in your region.

Implementing a biogas digester system represents a significant step toward both environmental sustainability and financial resilience for dairy operations. By capturing valuable resources from what was once considered waste, these systems create multiple revenue streams while addressing crucial environmental challenges.

As climate-smart agriculture continues gaining importance in policy and markets, early adopters position themselves advantageously for future opportunities.