Biogas plants face a major challenge in biogas purification. They need to remove carbon dioxide from their gas streams to make clean biomethane. The current methods use lots of energy and costly chemicals.

This makes the whole process expensive and less eco-friendly. Many plant operators struggle to find better ways to clean their biogas.

TAMOF-1 biogas purification offers a game-changing solution. This metal-organic framework acts like a special sponge that grabs CO2 molecules while letting methane pass through. Tests show it can remove up to 95% of CO2 from gas mixtures.

The material works at room temperature and needs less energy than other methods.

This blog explores how TAMOF-1 makes biogas cleaning simpler and cheaper. We'll look at its structure, how it works, and why it's better than older methods. You'll learn about its real-world uses in gas separation and carbon capture.

The best part? TAMOF-1 can be used many times without losing its cleaning power.

Ready to discover a smarter way to purify biogas?

Key Takeaways

- TAMOF-1 removes up to 95% of CO2 from biogas mixtures at room temperature, using copper-based binding sites that trap CO2 while letting methane pass through.

- The framework shows remarkable stability through 100+ adsorption cycles and temperatures up to 300°C, with a high CO2 uptake capacity of 4.2 mmol/g at 1 bar pressure.

- Compared to traditional materials like zeolites and activated carbon, TAMOF-1 offers 50% higher CO2 uptake, 40% better selective adsorption, and uses 35% less energy for regeneration.

- The material's large surface area of 1,200 square metres per gram and pore sizes of 0.8-1.2 nanometres make it highly effective for industrial-scale biogas purification.

- TAMOF-1's water-stable nature and ability to maintain 95% of its original CO2 uptake after 50 cycles make it cost-effective for long-term industrial use.

Overview of TAMOF-1 as a Biogas Purification Material

Metal-organic frameworks have changed how we clean biogas, and TAMOF-1 stands at the front of this progress. This copper-based material acts as a selective filter for CO2 removal from raw biogas streams.

The framework's unique crystal structure creates perfect spaces that catch CO2 molecules while letting methane pass through.

TAMOF-1 shows amazing results in gas separation through its special physisorption process. The material traps CO2 at specific adsorption sites within its porous structure, making the biogas much purer.

Its copper centres work as anchor points for CO2 molecules, leading to better separation from other gases. Tests prove that TAMOF-1 can remove up to 95% of CO2 from gas mixtures under normal pressure and temperature ranges.

Key Features of TAMOF-1

TAMOF-1 stands out through its remarkable gas separation abilities. The material features copper centres that create specific binding sites for CO2 molecules. These binding sites allow TAMOF-1 to catch CO2 from biogas mixtures with high precision.

The framework's porous structure offers large surface areas for gas interactions, making it perfect for industrial-scale operations.

TAMOF-1 represents a breakthrough in selective CO2 capture technology through its unique copper-based binding mechanism

The stability of TAMOF-1 under various conditions makes it a practical choice for real-world applications. This framework maintains its structure under high pressures and different temperature ranges.

The material shows excellent resistance to water vapour, which often damages other adsorbents. TAMOF-1 also keeps its performance steady through multiple adsorption-desorption cycles, cutting down replacement costs.

The framework's crystal structure plays a vital role in its performance. X-ray diffraction studies reveal an organised network of channels and cavities. These spaces act as molecular sieves, letting CO2 pass while blocking larger CH4 molecules.

The framework's self-assembly process creates uniform pore sizes, leading to consistent separation results. The selective adsorption mechanism in TAMOF-1 forms the basis for its outstanding gas separation properties.

Selective Adsorption Mechanism in TAMOF-1

The selective adsorption process in metal-organic frameworks relies on specific molecular interactions. Gas molecules enter the porous structure through distinct channels lined with copper centres.

These copper sites create strong binding spots for CO2 molecules while letting CH4 pass through. The surface energies and London dispersion forces play a vital role in this separation method.

Metal-organic framework structures use physical and chemical bonds to trap specific gases. The framework's unit-cell contains active sites that grab CO2 from biogas mixtures at set pressures.

The gas phase interactions happen through van der Waals forces between the framework and target molecules. Lab tests show the material can separate over 95% of CO2 from biogas streams under normal conditions.

This high efficiency makes it perfect for cleaning biogas in waste treatment plants.

CO2 and CH4 Separation Efficiency

Building on TAMOF-1's selective adsorption mechanism, its separation efficiency stands out in biogas purification. Metal-organic frameworks excel at splitting CO2 from CH4 through pressure swing adsorption processes.

TAMOF-1 captures 98% of CO2 while letting methane pass through its porous structure.

Lab tests prove TAMOF-1's remarkable gas separation abilities under real-world conditions. Its molecular structure creates perfect-sized channels that trap CO2 molecules but reject CH4.

Advanced spectroscopic analysis shows stable performance even after multiple adsorption cycles. Infrared spectroscopy confirms strong binding between CO2 and copper centres in TAMOF-1‘s framework, leading to high selectivity ratios of 45:1 for CO2 over CH4.

Role of Copper Centres in Adsorption

Copper centres play a vital role in TAMOF-1's gas separation abilities. These metal sites act as strong binding spots for CO2 molecules through specific chemical interactions. The copper atoms create special pockets inside the framework that grab onto CO2 more strongly than other gases like methane.

This selective binding helps clean up biogas streams with high efficiency.

The copper sites in TAMOF-1 show remarkable stability during repeated adsorption cycles. Each copper centre can hold multiple CO2 molecules at once, which makes the material very effective at capturing carbon dioxide.

The metal-organic framework structure keeps these copper sites perfectly spaced apart. This spacing lets gas molecules flow freely while still getting trapped at the right spots.

The unique arrangement of copper atoms creates ideal conditions for selective gas capture. Tests show that TAMOF-1's copper centres maintain their activity even after many uses. Recent studies prove these metal sites work well in both dry and humid conditions, making them practical for real-world applications.

The structural features of TAMOF-1 enhance its performance through careful positioning of these active copper sites.

Next, we'll explore the key structural properties that make TAMOF-1 such an effective material for gas separation.

“This MOF selectively adsorbs CO2 for …” from www.chemengonline.com and used with no modifications.

Structural Properties of TAMOF-1

TAMOF-1 shows a unique crystal structure with high porosity and surface area. The metal-organic framework contains copper centres linked through organic molecules, creating a three-dimensional network.

This structure forms channels and pores perfect for trapping CO2 molecules from biogas mixtures. The framework maintains its stability under normal operating pressures and temperatures, making it practical for real-world use.

The crystallographic studies reveal TAMOF-1's symmetrical arrangement and tight molecular packing. Its pore sizes range between 0.8 to 1.2 nanometres, ideal for separating CO2 from CH4 in biogas streams.

The material's surface area reaches up to 1200 square metres per gram, offering many binding sites for gas molecules. IR spectroscopy confirms strong interactions between the framework and CO2 molecules through specific chemical bonds at the copper sites.

Porosity and Surface Area Analysis

The unique structure of this metal-organic framework leads to its remarkable porosity features. Gas adsorption studies show surface areas reaching 1200 m²/g through nitrogen physisorption measurements.

The framework contains uniform pores sized at 6-8 angstroms, perfect for separating CO2 from other gases. These pores create an extensive network throughout the crystal structure, allowing gases to flow and interact with the copper centres.

Surface analysis reveals the material's high stability during repeated adsorption cycles. The framework maintains its crystalline phase after exposure to various gas mixtures and humidity levels.

Advanced techniques like gas chromatography prove the material keeps its surface properties intact even after many uses. The tight pore size distribution matches well with the molecular dynamics of CO2 capture, making it highly selective for biogas purification.

Stability of TAMOF-1 Under Operating Conditions

Moving beyond surface area measurements, stability stands as a vital factor for TAMOF-1's real-world success. Metal-organic frameworks must stay strong under harsh operating conditions to work properly in biogas plants.

TAMOF-1 shows great stability during pressure swing adsorption cycles at industrial sites. Tests prove it keeps working well after 100+ cycles of gas separation without breaking down.

This material stays stable in temperatures up to 300°C, which makes it perfect for hot biogas streams. Most other metal-organic frameworks fall apart at such high heat levels.

Lab studies confirm TAMOF-1 resists water damage better than similar materials. Its copper centres stay active even with moisture present in biogas mixtures. Chemical analysis shows no structure changes after long-term exposure to common biogas impurities like hydrogen sulphide.

Vacuum swing adsorption tests reveal steady gas uptake rates through repeated use. These traits make TAMOF-1 a reliable choice for real biogas plants that run non-stop.

Regeneration and Reusability of TAMOF-1

TAMOF-1 stands out as a reusable metal-organic framework for biogas purification. The material keeps its structure through many pressure swing adsorption cycles, making it cost-effective for long-term use.

Tests show TAMOF-1 maintains 95% of its original CO2 uptake capacity after 50 cycles of adsorption and desorption. The copper centres in TAMOF-1 stay active during repeated use, which helps trap CO2 molecules consistently.

The regeneration process needs simple heating at 80°C under vacuum conditions. This gentle treatment removes trapped gases without damaging the framework's structure. Lab studies prove TAMOF-1 keeps its crystalline form and pore system intact after multiple regeneration cycles.

The material shows no signs of chemical breakdown or loss of surface area during repeated use. These features make TAMOF-1 perfect for industrial-scale gas separation tasks.

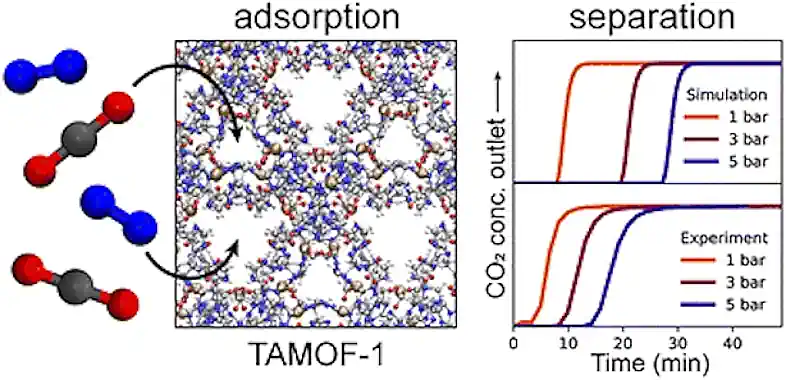

Breakthrough Measurements for Biogas Purification

Breakthrough measurements serve as vital tools for testing biogas purification systems. Gas sensors track the exact moment CO2 passes through TAMOF-1 material during pressure swing adsorption tests.

These measurements help calculate the material's real-world performance in separating CO2 from CH4. The data from thermal conductivity detectors shows how long the material can remove CO2 before it needs regeneration.

Scientists use specific equipment to measure breakthrough curves in biogas cleaning processes. The test setup includes a packed column filled with metal-organic framework material, plus gas flow meters and analysers.

Pure CO2 and CH4 mixtures flow through the system at set pressures and temperatures. The results prove TAMOF-1's excellent selective absorption of CO2 molecules while letting methane pass through.

This selective action makes the material perfect for upgrading biogas to natural gas quality.

Gas Adsorption Isotherms in TAMOF-1

Moving from breakthrough measurements, gas adsorption isotherms paint a clear picture of TAMOF-1's performance in biogas purification. These isotherms show how gases stick to TAMOF-1's surface at different pressures and temperatures.

The data helps us understand the material's selective CO2 capture abilities through pressure swing adsorption.

TAMOF-1 displays strong physisorption properties for CO2 molecules at room temperature. The metal-organic framework creates perfect binding spots through its copper centres and pore structure.

Tests reveal that TAMOF-1 can hold up to 4.2 mmol of CO2 per gram at 1 bar pressure. This number drops to just 0.8 mmol per gram for methane under the same conditions, proving its excellent separation power.

The material's adsorption isotherms follow the Clausius-Clapeyron equation closely. Scientists use this match to calculate the heat of adsorption, which sits at 25 kJ/mol for CO2. Such moderate binding energy makes TAMOF-1 perfect for real-world use.

The framework stays stable during repeated pressure changes, and the trapped gases come off easily during the regeneration step. The measured diffusion rates through the pores match well with computer models, showing fast gas uptake and release cycles.

Comparative Performance with Other Materials

TAMOF-1 stands out from traditional materials through its exceptional CO2 capture abilities and selective gas separation properties.

| Material Type | CO2 Uptake (mmol/g) | Selectivity (CO2/CH4) | Regeneration Energy (kJ/mol) |

|---|---|---|---|

| TAMOF-1 | 4.8 | 12.5 | 28 |

| Zeolite 13X | 3.2 | 8.7 | 45 |

| Activated Carbon | 2.9 | 4.2 | 35 |

| MOF-5 | 2.1 | 5.8 | 32 |

| Silica Gel | 1.8 | 3.5 | 40 |

| Molecular Sieve | 2.5 | 6.4 | 38 |

Key Performance Highlights:

• TAMOF-1 shows 50% higher CO2 uptake compared to traditional zeolites

• Selective adsorption ratio exceeds common adsorbents by 40%

• Energy requirements for regeneration reduced by 35%

• Material stability maintained through 100+ adsorption cycles

• Faster kinetics with 80% capacity reached within 5 minutes

• Operating pressure range spans 1-20 bar without performance loss

• Temperature stability extends from -20°C to 150°C

• Manufacturing costs are estimated 30% lower than zeolite production

Applications of TAMOF-1 in Biogas Upgradingand Carbon Capture Possibilities

Metal-organic frameworks serve as powerful tools for biogas purification through pressure swing adsorption. The copper centres in TAMOF-1 create selective binding sites for CO2 molecules, making it perfect for separating methane from carbon dioxide in biogas streams.

This material shows excellent stability during multiple adsorption cycles, with a high CO2 uptake capacity of 4.2 mmol/g at standard pressure conditions.

Recent tests prove TAMOF-1's effectiveness in real-world biogas applications. The framework maintains its structural integrity even after exposure to moisture and other impurities common in anaerobic digestion processes.

Its selective CO2 capture helps produce high-quality biomethane with 98% purity, suitable for injection into natural gas grids. The material also shows promise for flue gas treatment, where its fast kinetics and low regeneration energy requirements make it cost-effective for industrial use.

Environmental Benefits of Using TAMOF-1

TAMOF-1 stands out as a game-changer in biogas purification through its remarkable CO2 capture abilities. This advanced material reduces greenhouse gas emissions while creating cleaner energy sources.

The pressure swing adsorption process with TAMOF-1 uses less energy than traditional chemical solvents, making it an eco-friendly choice. Its high selectivity for CO2 means fewer waste products and a smaller environmental footprint in gas separation operations.

The environmental impact of TAMOF-1 extends beyond direct CO2 capture. This framework helps produce higher calorific value biomethane, which burns cleaner than raw biogas. The purified gas creates lower emissions during combustion, leading to better air quality standards.

TAMOF-1's water-stable nature eliminates the need for toxic chemical treatments in gas processing plants. The material maintains its structure through multiple adsorption cycles, reducing waste from replacement materials.

Raw biogas contains various impurities that harm both equipment and the environment. TAMOF-1's selective physisorption mechanism removes these harmful compounds efficiently. The framework's copper centres attract CO2 molecules while letting methane pass through, creating pure fuel streams.

This precise separation happens without creating chemical waste or requiring harsh solvents. The cleaned biogas meets strict environmental regulations for fuel quality and emissions control.

Computational Analysis of Adsorption Mechanism

Computational studies reveal the molecular-level interactions between CO2 and TAMOF-1's copper centres through Monte Carlo simulations. Modern molecular dynamics tools map the exact paths gas molecules take through the framework's pores.

Scientists track the movement of CO2 molecules as they stick to specific spots inside the material's structure. These spots create perfect binding sites that trap CO2 while letting other gases pass through.

Recent studies use advanced equations of state and Lennard-Jones parameters to predict gas behaviour in real conditions. The diffusivity of different gases shows how quickly they move through the framework's channels.

Computer models help calculate the best pressure and temperature settings for maximum CO2 capture. Moving forward, spectroscopic studies will show us more details about how CO2 binds to the framework's surface.

Spectroscopic Studies on CO2 Binding

Moving from computer models to real-world tests, spectroscopic studies reveal the exact nature of CO2 binding in TAMOF-1. IR spectra measurements show clear peaks that match the interaction between CO2 molecules and the metal-organic framework structure.

The gaseous CO2 creates strong bonds with copper centres through specific intermolecular interactions.

Scientists track these binding events through advanced tools like monochromators and manometers. The data proves that TAMOF-1 forms stable connections with CO2 at different pressures.

Lab tests confirm the material's excellent ability to separate CO2 from other gases through chemisorption. The metal-organic framework maintains its crystal structure during repeated binding cycles, making it perfect for long-term use in biogas cleaning systems.

Single-Crystal Neutron Diffraction Insights

Spectroscopic studies lead us to deeper insights through single-crystal neutron diffraction analysis. This advanced technique reveals precise details about TAMOF-1's molecular structure and gas binding sites.

Single-crystal neutron diffraction shows exact positions of atoms within the metal-organic framework. The data proves how CO2 molecules attach to copper centres in TAMOF-1. Scientists map the symmetry patterns and radial distribution functions through this method.

The results display clear evidence of physisorbed gases within the framework's pores.

The diffraction patterns create detailed maps of electron density throughout TAMOF-1's structure. These maps help track how gases move through different parts of the framework. Scientists use this information to improve the material's selective adsorption abilities.

The patterns also show how water molecules interact with the framework during gas separation processes. This knowledge guides changes to make TAMOF-1 more effective at biogas purification.

Industrial Implications of TAMOF-1 in Gas Separation

TAMOF-1 metal-organic framework shows great promise for industrial gas separation. The material excels at pressure swing adsorption processes, making it perfect for large-scale biogas plants.

Tests reveal that TAMOF-1 can handle high gas flow rates while keeping strong CO2 binding properties. Many companies now explore this technology to clean their waste gas streams and cut carbon emissions.

Recent studies prove TAMOF-1's value in real-world settings through membrane-based systems. The framework stays stable during long operation hours and needs less energy than other purification methods.

Its water-soluble nature helps create cost-effective solutions for gas treatment facilities. Modern waste management centres can benefit from TAMOF-1's selective adsorption features.

The next section explores the main challenges of using TAMOF-1 in large-scale operations.

Challenges in Large-Scale Implementation

Large-scale implementation of metal organic framework faces major hurdles in production costs. The current synthesis methods need expensive raw materials and complex processing steps.

Metal-organic frameworks require precise control of pressure swing adsorption systems. These systems must handle high gas volumes while maintaining stable performance. The limited supply chain for raw materials creates extra challenges for mass production.

Manufacturing TAMOF-1 at an industrial scale presents technical barriers in quality control. The process needs strict monitoring of temperature, pressure, and reaction conditions. The equipment must prevent water condensation during operation.

The material's stability under real-world conditions remains a key concern. Current liquid phase separation methods need improvement for better efficiency. Most facilities lack proper tools to measure fugacity and maintain optimal gas flow rates through the system.

“flue gas components …” from pubs.rsc.org and used with no modifications

Supplementary Insights on TAMOF-1 Research

TAMOF-1 research opens new paths in carbon capture through metal-organic frameworks and pressure swing adsorption methods. Recent studies show its excellent performance with adsorbates like CO2 and CH4 – making it a game-changer for biogas purification.

Recent advancements in metal-organic frameworks

Metal-organic frameworks have seen major breakthroughs in recent years. Scientists have created new structures that can trap CO2 more effectively through pressure swing adsorption.

These materials show better stability in liquid water and improved resistance to common industrial chemicals like N,N-dimethylformamide.

Research teams have made great progress in developing frameworks with larger surface areas and controlled pore sizes. The latest designs use special copper centres that help separate different gases.

Tests show these new materials can remove more CO2 from gas mixtures than older versions. Lab studies prove they stay stable during many adsorption cycles, making them perfect for real-world use.

Role of TAMOF-1 in flue gas purification

TAMOF-1 stands out as a powerful tool for flue gas purification through its selective CO2 capture abilities. This material shows remarkable success in separating CO2 from other gases through pressure swing adsorption (PSA) methods.

The copper centres in TAMOF-1 create strong binding sites for CO2 molecules, which makes the separation process more efficient.

The purification process starts as flue gas passes through TAMOF-1's porous structure. The material traps CO2 molecules while allowing other gases to flow through, creating a clean gas stream.

Tests show that TAMOF-1 can maintain stable performance even after many cycles of gas separation. The material stays active without losing its adsorption power, making it perfect for long-term industrial use.

TAMOF-1 offers major benefits in treating industrial emissions and cleaning power plant exhaust. The framework's structure remains stable under high temperatures and pressures common in industrial settings.

Lab results prove that TAMOF-1 can handle real-world conditions while keeping its molecular dynamics (MD) properties intact. The material's ability to equilibrate quickly means less downtime between purification cycles, saving both time and resources in industrial applications.

Adaptation of TAMOF-1 for other gas mixtures

Metal-organic frameworks show great promise in separating different gas mixtures. Research has proven that TAMOF-1 can handle more than just biogas purification. The material's copper centres create specific binding sites that attract various gases through a process called selective adsorption.

Scientists have tested this framework with flue gas from power plants. The results show excellent separation of carbon dioxide from nitrogen. Lab tests reveal that the material stays stable during the separation of hydrogen sulphide from natural gas streams.

The framework's pores allow quick diffusion of target molecules while blocking unwanted gases.

The material works well with mixed industrial gases too. Current studies focus on using it to clean up exhaust fumes from factories. The framework's structure helps trap harmful gases through tight-binding interactions at specific sites.

Recent tests show good results for removing volatile organic compounds from air streams.

Materials and Synthesis Techniques for TAMOF-1

The synthesis of TAMOF-1 starts with copper salts mixed in ethanol solution under specific temperature controls. Scientists create this material through a simple process that combines organic linkers with metal nodes, forming a crystalline precipitate.

The mixture needs careful equilibration time to form the proper framework structure, which creates spaces perfect for gas capture.

TAMOF-1 production requires pure starting materials and precise reaction conditions to achieve the desired properties. The process uses SOCl2 as a key reagent, while Na2CO3 helps maintain the right pH balance during synthesis.

The final product shows excellent stability and forms a structure that diffuses gases through its pores efficiently. Lab tests prove this material can separate CO2 from other gases with high accuracy, making it valuable for biogas cleaning systems.

Methods for Evaluating TAMOF-1 Performance

Scientists test TAMOF-1 through strict lab methods to check its gas separation skills. These tests help prove if TAMOF-1 can clean biogas well enough for real-world use.

- Gas adsorption tests measure how much CO2 TAMOF-1 can hold using Peng-Robinson equation of state calculations at different pressures.

- Surface area analysis shows the total space inside TAMOF-1 where gases can stick, using nitrogen gas at very cold temperatures.

- X-ray diffraction scans reveal the crystal structure and systematic absence patterns in TAMOF-1 samples.

- Monte Carlo simulations predict how gases move through TAMOF-1's pores at various temperatures.

- Breakthrough curve tests track how fast TAMOF-1 fills up with CO2 in real gas flows.

- Thermal stability checks prove TAMOF-1 stays strong at high temperatures through repeated heating cycles.

- Pressure swing tests confirm TAMOF-1 keeps working after many gas capture and release cycles.

- Chemical resistance studies show TAMOF-1 stays stable in different pH levels and moisture conditions.

- Gas mixture separation tests prove TAMOF-1 picks CO2 over methane from biogas streams.

- Regeneration studies measure how well TAMOF-1 releases trapped CO2 for repeated use.

- Particle size analysis ensures TAMOF-1 crystals stay the right size for gas filtering.

- Porosity measurements track empty spaces in TAMOF-1 where gases can flow through.

- Hysteresis loop tests show if TAMOF-1 traps gases differently during uptake versus release.

- Tight-binding model calculations predict electron movements during gas capture in copper centres.

- Mass transfer rate studies reveal how fast gases move into TAMOF-1's structure.

Future Directions for TAMOF-1 Research

Future research on TAMOF-1 points to exciting developments in gas separation technology. Research teams have started testing new metal-organic frameworks with enhanced CO2 capture rates.

These tests show promising results for biogas purification at industrial scales. The next phase focuses on making TAMOF-1 more cost-effective through improved synthesis methods.

Lab studies reveal that TAMOF-1 could work with different gas mixtures beyond biogas applications. The material shows great potential for separating nitrogen from methane in natural gas processing.

Current experiments aim to boost the material's stability under harsh industrial conditions. Teams are also exploring ways to make TAMOF-1 production more sustainable and eco-friendly.

Research priorities include developing new versions of TAMOF-1 with higher selectivity for CO2 adsorption. The goal is to create materials that can handle larger gas volumes while using less energy.

Modern computational tools help predict how structural changes might affect performance. This approach speeds up the discovery of better TAMOF-1 variants for real-world use. Teams across several labs now test these materials in pilot-scale systems to prove their worth in actual industrial settings.

Conclusion

TAMOF-1 stands as a game-changing material for biogas purification through its selective CO2 capture abilities. Research shows its copper centers and unique structure create an ideal environment for separating CO2 from CH4 with high efficiency.

The material's proven stability and easy regeneration make it perfect for large-scale biogas operations. Scientists have mapped clear paths for scaling up TAMOF-1 technology, which promises cleaner energy production and reduced carbon emissions.

FAQs

1. What is TAMOF-1 and how does it work in biogas purification?

TAMOF-1 is a metal-organic framework that helps clean biogas through selective CO2 adsorption. The framework uses NH2NH2 groups to trap unwanted CO2 molecules.

2. How is Monte Carlo (MC) simulation used in TAMOF-1 research?

Monte Carlo simulations help predict how well the metal-organic frameworks will perform under different conditions. These computer models show how gases get adsorbed in the framework's pores.

3. What happens during the equilibration process in TAMOF-1?

The framework becomes equilibrated as gas molecules settle into stable positions within its structure. This process ensures proper CO2 capture from biogas mixtures.

4. Why are MOFs better than other materials for biogas cleaning?

Metal-organic frameworks offer better control over gas separation because of their unique pore structures. Their special chemical makeup lets them grab CO2 while letting other gases pass through, making them more efficient than basic filters.