A biogas reactor transforms organic waste into valuable methane gas through anaerobic digestion, creating both clean energy and nutrient-rich digestate. This airtight chamber breaks down organic matter without oxygen, producing biogas that can power homes, heat buildings, or generate electricity.

The process tackles two problems at once: waste disposal and energy production. Many turn to renewable energy sources but face confusion about which systems actually work for their specific needs.

This guide explains how biogas reactors work, from small household units to large commercial biogas plants. You'll discover the anaerobic digestion process, learn about different reactor designs, and understand why biogas production sometimes slows down.

We'll also explore proven strategies to fix common operational problems and maximise your biogas output.

Ready to turn your waste into energy?

Key Takeaways

- Biogas reactors transform organic waste into methane gas through anaerobic digestion, producing renewable energy whilst reducing greenhouse gas emissions from landfills.

- Small-scale systems handle household waste whilst large-scale reactors process sewage sludge, requiring proper insulation and temperature control for optimal performance.

- Biogas slowdowns occur from temperature fluctuations, pH imbalances, and toxic metabolite accumulation, requiring immediate operator intervention to prevent system failure.

- Recovery strategies replacing 50% reactor content with fresh cattle gel restore gas production within six days, proving more effective than water dilution.

- Technical University of Denmark trials showed that combining manure with degassed biomass delivers 42% to 74% increased gas production after inhibition events.

What is a biogas reactor? And “slowdown

What is a Biogas Reactor?

A biogas reactor transforms organic waste into clean energy through anaerobic digestion, where bacteria break down materials like food scraps and animal manure without oxygen. This sustainable technology produces methane gas for renewable electricity whilst reducing greenhouse gas emissions from landfill sites.

Definition and purpose

A biogas reactor serves as an airtight chamber that transforms organic materials into valuable energy and fertiliser products. This innovative system uses anaerobic treatment technology to break down organic waste, animal manure, food scraps, and sewage sludge without oxygen.

The reactor creates an enclosed environment where bacteria naturally decompose organic matter through anaerobic digestion.

These systems produce two main outputs that benefit both energy production and agriculture. Biogas emerges as the primary energy product, containing methane gas and carbon dioxide that can generate renewable electricity or heat.

Digestate forms the second valuable output, creating a nutrient-rich fertiliser that remains nearly odourless and contains partially inactivated pathogens. The reactor's design allows gas pressure from biogas production to transport the methane gas to storage areas or direct use points.

The fermentation process within the reactor generates gas that collects at the top and mixes with the slurry as it rises.

Understanding the components that make these reactors function requires examining their essential parts and construction methods.

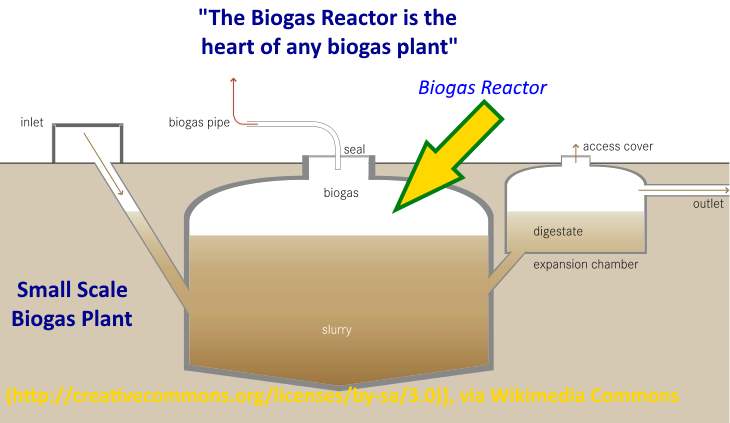

Components of a biogas reactor

Understanding the purpose of biogas reactors leads naturally to examining their essential components. Each part works together to create the perfect environment for anaerobic digestion and renewable energy production.

- Feed inlets serve as entry points where organic waste, animal manure, and food scraps enter the anaerobic digester system for processing.

- The digester chamber forms the main fermentation vessel where organic matter undergoes anaerobic decomposition to produce methane gas and carbon dioxide.

- Gas outlets collect and channel biogas from the digester to storage tanks or directly to electricity generation equipment.

- Slurry outlets remove digestate and processed organic material from the reactor after the anaerobic digestion process completes.

- Mixing mechanisms ensure proper circulation of feedstock and maintain optimal conditions for acetogenic bacteria and other microorganisms.

- Airtight sealing systems prevent gas leaks and maintain essential anaerobic conditions required for methane production and clean energy generation.

- Structural framework provides vital integrity to withstand internal pressures from biogas production and external environmental factors affecting the system.

- Insulation materials retain heat within fixed dome digesters and other reactor types to optimise bacterial activity and biogas output.

- Access points enable maintenance teams to monitor biogas systems' performance and conduct necessary repairs on anaerobic digestion plants.

Biogas Production Process

Biogas production relies on anaerobic digestion, where bacteria break down organic matter without oxygen to create methane gas and carbon dioxide. This natural process transforms food waste, animal manure, and other organic materials into renewable energy while producing nutrient-rich digestate for agricultural use.

Anaerobic digestion

Bacteria break down organic matter without oxygen during anaerobic digestion. This natural process transforms animal manure, food waste, and municipal wastewater into valuable biogas and nutrient-rich digestate.

The breakdown occurs through four distinct stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis. Each stage plays a crucial role in converting complex organic compounds into simpler molecules that eventually become methane gas and carbon dioxide.

Microbial communities work together inside sealed reactors to facilitate this transformation. The process operates best at pH levels between 6.5 and 8, creating optimal conditions for acidogenic bacteria and other microorganisms.

Typical retention periods last approximately three weeks, allowing sufficient time for complete decomposition of agricultural waste and food scraps. This renewable energy source produces biogas containing primarily methane and carbon dioxide, whilst generating digestate that requires pasteurisation to meet regulatory standards for safe use as fertiliser.

Anaerobic digestion represents one of nature's most efficient recycling systems, converting organic waste into clean energy whilst reducing greenhouse gas emissions.

Generation of biogas and digestate

Microorganisms and bacteria break down biomass in the absence of oxygen to produce biogas through anaerobic digestion. This process creates two valuable products: biogas and digestate.

The biogas contains methane gas, which serves as a renewable energy source for generating electricity, heat, or light production. Carbon dioxide also forms during this breakdown process alongside the methane emissions.

Digestate emerges as the solid and liquid material remaining after anaerobic decay completes. Operators separate this digestate into liquid and solid fractions for agricultural use on farming land.

The material contains essential nutrients and remains nearly odourless, making it an excellent fertiliser for crops. This nutrient-rich digestate helps recycle organic matter back into the soil whilst reducing the original organic waste volume significantly.

Small-Scale Biogas Reactors

Small-scale biogas reactors offer households and farms a practical way to convert organic waste into renewable energy. These compact systems turn food scraps and animal manure into methane gas through anaerobic digestion, providing clean energy for cooking and heating while reducing greenhouse gas emissions.

Design and operation

Biogas digesters for household and community use require careful planning and simple operation methods. These systems transform organic waste into renewable energy through anaerobic digestion processes.

- Fixed dome digesters use concrete construction and remain buried underground to maintain stable temperatures for methane production.

- Floating drum designs feature movable gas collectors that rise and fall with biogas production levels inside the reactor chamber.

- Balloon-type reactors employ flexible plastic materials that expand during gas generation and contract when biogas gets extracted for use.

- Local materials like bricks, cement, and steel reduce construction costs while ensuring the system remains economically viable for rural communities.

- Underground installation protects the reactor from temperature fluctuations and maximises space efficiency on agricultural land.

- Temperature control systems maintain optimal conditions between 30-40°C to support efficient anaerobic degradation of organic matter.

- Stirring mechanisms prevent solid biomass from settling and ensure proper mixing of animal manure with other feedstock materials.

- Real-time monitoring equipment tracks gas production rates, pressure levels, and hydraulic retention time for optimal performance.

- Parameter control systems regulate pH levels, moisture content, and carbon-to-nitrogen ratios to prevent operational disturbances.

- Integration with on-site sanitation facilities allows co-treatment of faecal sludge alongside food scraps and animal waste materials.

- Regular maintenance schedules include sludge removal, gas line cleaning, and equipment checks to sustain long-term biogas production efficiency.

Feedstock and co-treatment with toilets

Proper design and operation create the foundation for effective feedstock management in small-scale biogas reactors. Many systems integrate toilets directly with biogas reactors to enable co-treatment of blackwater alongside organic waste materials.

This approach maximises resource recovery whilst reducing waste management costs for households and communities.

Small-scale biogas reactors typically receive animal manure and organic wastes such as kitchen scraps and garden waste as their primary feedstock. Toilets connected to these systems provide additional organic matter through blackwater, creating a comprehensive waste treatment solution.

Co-digestion of manure with kitchen waste delivers a balanced nutrient supply that supports stable anaerobic digestion processes and consistent methane gas production.

Large-Scale Biogas Reactors

Large-scale biogas reactors handle massive amounts of organic waste from sewage treatment plants and industrial facilities. These systems require proper insulation and advanced construction techniques to maintain optimal temperatures for anaerobic digestion throughout the year.

Construction and insulation

Building large-scale biogas reactors requires careful attention to materials and thermal management. Proper construction ensures long-term durability whilst effective insulation maintains optimal conditions for anaerobic digestion.

- Circular steel tanks form the foundation – Most large-scale biogas plants use insulated circular steel tanks as their primary construction material, providing strength and airtightness for efficient methane gas production.

- Insulation retains essential heat – Thermal barriers help maintain consistent temperatures needed for anaerobic digestion, improving biogas upgrading efficiency and reducing energy demand from external heating sources.

- Material selection affects reactor longevity – Steel construction with proper coatings resists corrosion from organic waste breakdown, ensuring stable operation when processing animal manure and sewage sludge.

- Airtight sealing prevents gas leakage – Proper welding and gasket installation eliminate methane emissions whilst maintaining pressure for optimal renewable energy production from organic matter.

- Access points enable maintenance – Commercial reactors incorporate inspection hatches and monitoring ports, allowing operators to check conditions without compromising the anaerobic environment.

- Size varies with application needs – Construction scales from small farm digesters managing food scraps to municipal facilities processing complex waste from wastewater treatment plants.

- Thermal efficiency reduces operational costs – Well-insulated tanks require less external heating, making biogas a more competitive renewable energy source compared to fossil fuels.

- Durability supports circular economy goals – Robust construction ensures reactors operate reliably for decades, maximising return on investment whilst reducing greenhouse gas emissions from organic waste disposal.

Management of sludge from sewage treatment facilities

Once large-scale biogas plants establish proper construction and insulation, operators must focus on managing sludge from sewage treatment facilities effectively. These commercial biogas plants handle organic waste from municipal sewage systems, transforming this material into renewable energy through anaerobic digestion processes.

Sludge management requires careful attention to chemical composition, particularly protein and fat content levels. High protein and fat concentrations create elevated ammonium and LCFA levels that inhibit biogas production significantly.

Operators monitor incoming sludge quality to maintain stable digestion conditions and prevent operational disturbances that reduce methane gas output.

Biogas Slowdowns and Operational Disturbances

Biogas plants can experience sudden drops in methane production, disrupting the steady flow of renewable energy. These operational setbacks often stem from temperature changes, pH imbalances, or contamination that affects the anaerobic digestion process.

Causes of biogas output drops

Process disturbances significantly reduce both economic and environmental performance due to decreased methane yields. Several factors can disrupt the delicate balance within anaerobic digestion systems and cause substantial drops in renewable energy production.

- Unfavourable process temperatures disrupt microbial activity and slow down organic matter breakdown. Temperature fluctuations prevent bacteria from efficiently converting animal manure and food scraps into methane gas.

- Feedstock variability and inconsistent supply create instability in the anaerobic digestion process. Irregular delivery of organic waste materials disrupts the hydraulic retention time and affects overall system performance.

- Microbial overload from excessive organic loading rates overwhelms the system's capacity to process materials effectively. High volumes of organic matter can lead to acid accumulation and severe process imbalances.

- Accumulation of inhibiting metabolites such as hydrogen, ammonium, and hydrogen sulphide poison the microbial community. These toxic compounds prevent bacteria from producing biogas and can shut down the entire system.

- Improper biomass composition and management affects the reactor's ability to maintain stable conditions. Poor quality feedstock or incorrect mixing ratios can create hazardous and odorous conditions that halt production.

- pH imbalances from acid accumulation disrupt the optimal environment needed for methane production. Acidic conditions kill essential bacteria and prevent the conversion of organic waste into renewable natural gas.

- Nutrient deficiencies or toxicity limit microbial growth and activity within the reactor vessel. Insufficient trace elements or excessive concentrations of certain compounds can severely impact biogas output.

- Mechanical failures in mixing or heating systems prevent proper distribution of materials and temperature control. Equipment breakdowns disrupt the continuous process required for efficient anaerobic digestion.

Operator responses and strategies

Biogas slowdowns require swift action from operators to prevent complete system failure. Experienced operators face these operational disturbances regularly, despite their expertise.

- Reduce feed rates immediately – Operators may respond to slowdowns by reducing the feed rate or ceasing feeding to allow the reactor to stabilise. This strategy gives the anaerobic digestion process time to recover naturally.

- Monitor feeding adjustments closely – Monitoring the effects of feeding adjustments on biogas production is essential for recovery. Operators track methane gas output levels to gauge system response.

- Dilute problematic biomass – Diluting biomass or adding fresh or degassed biomass can help rectify known imbalances. This approach reduces toxic concentrations that inhibit organic matter breakdown.

- Add fresh organic material – Fresh animal manure or food scraps can restore healthy microbial populations. New biomass provides essential nutrients for bacterial communities in the reactor.

- Implement complete feeding cessation – Stopping all feedstock input allows severely stressed systems to stabilise. This drastic measure prevents further damage to the anaerobic digestion process.

- Adjust hydraulic retention time – Extending retention periods gives organic waste more time to digest properly. Longer processing times can improve biogas output from existing material.

- Test different recovery approaches – There is no standardised procedure that guarantees successful recovery from slowdowns. Operators must experiment with various strategies to find effective solutions.

- Prepare for financial consequences – Severe slowdowns can lead to a complete breakdown of the digestion process with financial implications. Quick response minimises economic losses from reduced renewable energy production.

Understanding inhibition factors becomes crucial for preventing future operational problems in biogas plants.

Inhibition of Biogas Reactors

Poor management of organic waste and animal manure can severely damage biogas plants and reduce methane gas production. These operational failures create toxic conditions that stop anaerobic digestion and force operators to restart their entire renewable energy systems.

Effects of improper biomass management

Improper biomass management creates serious problems in biogas reactors. High protein concentrations lead to ammonium accumulation, which poisons the anaerobic digestion process. Fat-rich organic waste causes LCFA (long-chain fatty acid) buildup that disrupts methane production.

Both types of contamination produce similar negative effects on biogas output and can shut down entire systems.

Biogas plants face greater risks when they accept external organic matter from multiple sources. Variable feedstock composition makes it difficult to maintain stable reactor conditions.

Inadequate monitoring practices allow toxic substances to build up undetected. Operators must understand the chemical characteristics and biodegradability of all incoming organic waste to prevent reactor failure and maintain steady renewable energy production.

Strategies for recovery after inhibition

Biogas reactors that suffer from improper biomass management require swift action to restore normal operations. Recovery strategies can dramatically reduce downtime and return methane production to optimal levels.

- Replace 50% of reactor content with degassed biomass or fresh cattle gel to achieve the fastest recovery. This method restores original gas production levels in approximately six days.

- Combine fresh cattle gel with degassed biomass for the most effective and secure recovery approach. This strategy increases gas production by 42% to 74% over other methods after six days.

- Add fresh cattle gel alone to boost methane gas output significantly. Fresh manure provides essential nutrients that support anaerobic digestion processes during recovery.

- Avoid diluting reactor contents with 50% water as this prolongs recovery time to 10 to 11 days. Water dilution ranks among the least effective recovery approaches.

- Maintain daily manure supply at normal levels during recovery operations. Ceasing or reducing organic waste inputs extends recovery time and delays restoration.

- Monitor oxygen levels closely during recovery as reactors without interventions show the highest increases. Elevated oxygen indicates process instability in biogas plants.

- Implement immediate intervention rather than taking no action. Simply doing nothing represents the least effective approach for restoring renewable energy production.

- Focus on biomass replacement over dilution methods for faster results. Degassed organic matter provides better foundation for renewed methane emissions than water additions.

Research and Experiments

Scientists at the Technical University of Denmark and the University of Southampton have conducted extensive trials to understand biogas reactor failures and recovery methods. Their experiments focused on trace nutrient deficiencies and biomass management strategies that help operators restore methane production after system inhibition occurs.

Trials conducted by the Technical University of Denmark

The Technical University of Denmark's Department of Environment and Resources conducted groundbreaking trials to revive stalled biogas processes. These experiments formed part of the Energy Research Program, which focused on reinstating biogas production in laboratory reactors.

Researchers tested various recovery strategies including diluting biomass with water, manure, or degassed biomass to restore proper anaerobic digestion.

Four reactors containing cattle gel were deliberately inhibited using ammonium or long-chain fatty acids (LCFA) to simulate real-world biogas process failures. The trials compared different recovery interventions to determine the most effective methods for restoring organic waste processing.

Results showed that replacing 50% of reactor contents with degassed biomass or fresh cattle gel proved most successful. Gas production and oxygen level evolution were carefully monitored throughout the experiments to assess process stability and methane gas generation rates.

Trace nutrient inhibition studies by the University of Southampton

Building on the Danish research, Professor Charles Banks of the University of Southampton conducted extensive studies on trace nutrient inhibition in anaerobic digestion systems. His research emphasised the critical importance of trace elements like zinc, copper, selenium, nickel, and cobalt in maintaining stable biogas production.

Banks discovered that deficiencies in these essential nutrients can result in reduced biogas yields and process instability across biogas plants.

Professor Banks' seminal research revealed that optimal concentrations of trace elements are necessary to maintain effective microbial activity during organic waste breakdown. Excess levels of these same nutrients may prove toxic and hinder digestion efficiency, creating a delicate balance that operators must maintain.

His studies recommend regular monitoring of trace element levels in digestate to ensure optimal methane gas production and prevent costly operational disruptions in renewable energy systems.

Outcomes of recovery strategies

Research from the Technical University of Denmark reveals clear patterns in biogas reactor recovery methods. Replacing 50% of reactor content with degassed biomass efficiently restored gas production levels in ammonium-inhibited systems.

Fresh cattle gel produced remarkable results, delivering a 42% to 74% increase in gas production compared to other recovery methods after six days. Water dilution accelerated recovery compared to no intervention, yet resulted in lower overall gas production rates.

The combination of manure and degassed biomass produced the best results for stabilising biogas production. Reactors with no interventions recorded the highest increase in oxygen levels, indicating severe process instability.

Recovery from LCFA inhibition showed similar challenges and patterns to ammonium-induced problems. Limited intervention leads to poor recovery outcomes and extended process instability, making proper management essential for maintaining renewable energy output from organic waste processing systems.

Conclusion to the question of What is a Biogas Reactor?

Biogas reactors represent a powerful solution for converting organic waste into clean energy whilst reducing greenhouse gas emissions. These systems transform animal manure, food scraps, and other biodegradable materials through anaerobic digestion, creating methane gas and valuable digestate.

Operators must stay alert to biogas slowdowns and respond quickly when production drops occur. Understanding biomass characteristics and maintaining proper feeding schedules helps prevent reactor inhibition.

Biogas technology offers communities and industries a sustainable pathway to generate renewable electricity while supporting the circular economy.

FAQs

1. What is a biogas reactor, and how does it work?

A biogas reactor uses anaerobic digestion to break down organic waste and animal manure without oxygen. This process creates methane gas and carbon dioxide, which provide a renewable energy source. The organic matter decomposes in sealed containers where bacteria anaerobically digest the materials.

2. What materials can go into biogas plants?

Biogas plants accept food scraps, animal manure, energy crops, and other organic waste materials. Sewage gas from septic tanks and faecal sludge treatment facilities also works well. These diverse sources of energy help create a circular economy approach to waste management.

3. How does biogas help reduce greenhouse gas emissions?

Biogas captures methane emissions that would otherwise escape from landfill gas sites or composting areas. This renewable electricity replaces fossil fuels and helps decarbonise energy systems. The process also reduces the environmental impact of organic waste disposal.

4. What types of biogas reactors exist?

Fixed dome digesters represent one common design for biogas upgrading systems. Different reactor types vary in hydraulic retention time and capacity. Some facilities use thermal gasification alongside traditional anaerobic processes.

5. Why might biogas production slow down?

Temperature drops, pH imbalances, or contaminated feedstock can reduce biogas output. Insufficient hydraulic retention time also affects gas production rates. Poor maintenance of biogas plants creates additional slowdown issues.

6. How does biogas compare to other clean energy sources?

Biogas provides consistent renewable energy unlike utility-scale solar systems that depend on weather. Feed-in tariffs often support biogas projects alongside biodiesel and bioethanol programmes. This sustainable energy source works continuously while helping sanitise organic waste streams.

References

- https://blog.anaerobic-digestion.com/what-is-a-biogas-reactor/

- https://www.nationalgrid.com/stories/energy-explained/what-is-biogas (2023-02-23)

- https://anaerobic-digestion.com/biogas-production-process/

- https://pmc.ncbi.nlm.nih.gov/articles/PMC10789629/

- https://www.sciencedirect.com/science/article/pii/S2772427123000323

- https://www.mdpi.com/1996-1073/12/3/365

- https://www.sciencedirect.com/science/article/pii/S2211715624002455

- https://pmc.ncbi.nlm.nih.gov/articles/PMC7797170/

- https://www.researchgate.net/publication/330471049_The_Influence_of_Trace_Elements_on_Anaerobic_Digestion_Process (2025-08-10)

- https://www.sciencedirect.com/science/article/pii/S0957582024006608

[First uploaded Jul 2017. Updated 10 December 2021. Rewritten September 2025.]

I had a biogas slowdown last year. At first we did not know the cause but analysis showed ammonia was too high. We made adjustments and got a new susbstrate source. All sites must take care, but if the slowdown occurs don’t take too hasty a move. Sit tight and analyze to find out cause. We nearly made wrong decision. Must make right decisions. High risk of income loss.

What percentage of biogas reactors go bad a year? I’d like to see some research on that before I invest in such a technology.

Since Prof Charles Banks of the University of Southampton completed research on this problem there is no reason why any digester would ‘go bad’. He published his research in a seminal paper. Just make sure your food waste reactor is given the essential trace compounds he identified in the research, and keep the ammonia concentration within a sensible level. See this link for the details.