The very quick answer to the question of “How Does A Biogas Plant Work?” is “very well – for your organic waste disposal, energy supply and fertilizer needs! But, if you want a more detailed answer read on.

Dealing with waste is a growing problem. Food scraps, sewage sludge, and agricultural leftovers often end up in landfills, adding to methane emissions and wasting potential energy.

Many wonder if there’s a smarter way to manage this mess while helping the planet.

Here’s one answer: biogas plants. These facilities turn organic waste into clean energy through anaerobic digestion. It’s like nature’s recycling system but faster and controlled.

This process doesn't just dispose of waste; it creates sustainable fuel and fertiliser too.

In this blog, you'll learn “how does a biogas plant work”. From breaking down food waste to producing renewable gas, we'll cover every step simply and clearly. Ready for the breakdown? Keep reading!

Key Takeaways

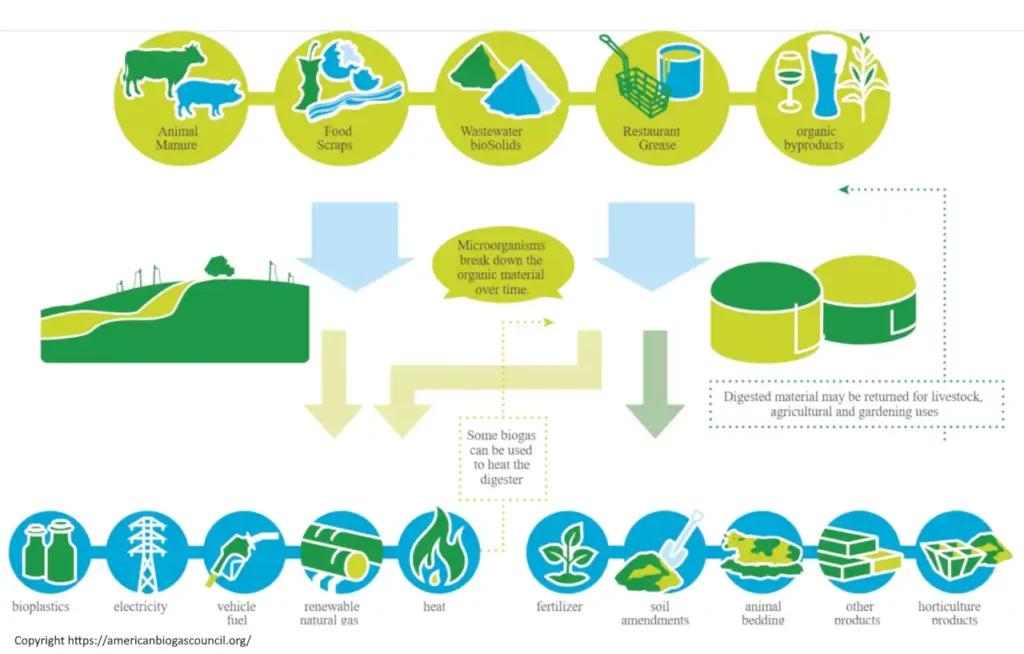

- Biogas plants convert organic waste like food scraps and manure into renewable energy using anaerobic digestion. This process produces biogas (mainly methane) and digestate, a nutrient-rich fertiliser.

- The key steps include pre-treating waste, feeding it into a digester tank, digesting it at controlled temperatures (38-56°C), capturing gas, and either use it as it is in a gas engine to make electricity or “upgrade” it (just get hold of the methane content) as biomethane for much more easily (and profitably) sold energy use.

- In 2019, over 132,000 digesters worldwide contributed to clean energy efforts by reducing carbon emissions and replacing fossil fuels with renewable options.

- Residual digestate from the process serves as an eco-friendly alternative to synthetic fertilisers in farming. It supports greener agriculture while promoting circular economies.

- Applications of biogas range from electricity production to a clean-burning renewable vehicle fuel like compressed natural gas (CNG) or liquefied natural gas (LNG), helping reduce air pollution globally.

Key Steps in How a Biogas Plant Works

“How Biogas Systems Work | American …” from americanbiogascouncil.org and used with no modifications.

A biogas plant works by breaking down organic materials, like food waste or animal manure, in a controlled environment. This process produces renewable gas and useful by-products through fermentation, turning waste into energy.

Pre-treatment and filling the digester

Food waste must be cleaned of plastics and other rubbish. Depackaging machines separate materials like packaging from organic matter. Farmers also add livestock manure, crop leftovers, or grass silage to the mix.

These steps keep contaminants out of the digester.

After pre-treatment, workers load the biomass into a feedstock input system. This system sends it into an anaerobic digester tank. Without oxygen, bacteria break down this organic material during fermentation later on.

Correct filling helps maintain gas production efficiency while reducing maintenance issues caused by blockages or impurities inside the tank.

The fermentation process

Microorganisms break down organic material in airtight tanks. This process, called anaerobic digestion, occurs at 38-40°C with constant mixing. Stainless steel fermenters can even handle temperatures up to 56°C and last decades without corrosion.

Nature's recyclers never take a day off.

Waste materials like manure or food scraps decompose into biogas and digestate. Biogas contains methane and carbon dioxide, making it a renewable energy source. The by-product, digestate, has fewer odours than raw manure but is rich in nutrients for fertiliser.

Producing biogas

Biogas forms through anaerobic digesters breaking down organic waste. Inside the digester, bacteria consume materials like agricultural waste or sewage gas in oxygen-free conditions.

This process releases gases, mainly methane (50-75%) and carbon dioxide (25-50%), along with trace amounts of hydrogen sulphide.

Once captured, biogas can power combined heat and power (CHP) plants to generate renewable electricity and heat. It’s also upgraded to biomethane for use as compressed natural gas or liquefied natural gas.

In 2019 alone, 132,000 digesters operated globally, proving this method's impact on reducing carbon emissions while creating sustainable energy sources.

Removing residues and impurities

After producing biogas, the gas must be cleaned. Impurities like hydrogen sulphide and moisture are removed to upgrade it into biomethane. This clean fuel is renewable and can replace natural gas for energy production.

The leftover digestate, after fermentation, gets separated from the biogas. It serves as a substitute for synthetic fertilisers in farming. The process also captures enriched CO2 during biogas upgrading, reducing greenhouse emissions while supplying industries such as food packaging or dry ice manufacturing.

Components of a Biogas Plant

A biogas plant is like a well-oiled machine, with vital parts working together to turn waste into clean energy—each component plays its role in making the process efficient and sustainable.

Depackaging and separation equipment for food waste and contaminant removal especially plastics

Food waste often comes mixed with plastics, labels, or other contaminants. Depackaging and separation equipment plays a vital role in handling this mess. Depackaging and Separation Machines strip unwanted materials like plastic wraps from food waste.

These devices ensure clean feedstock enters the biogas plant.

About 1.3 billion tonnes of food go to waste every year globally. With such volumes, efficient sorting systems reduce landfill waste while boosting renewable fuel production. Removing contaminants also prevents damage to biodigesters during processing.

Next up is understanding the feedstock input system!

Feedstock input system

Biogas plants rely on an effective feedstock input system. This part moves organic materials like crop residues, animal waste, or municipal wastewater into the digester. The system prevents clogging by handling solid biomass and liquids evenly.

Waste separation happens before this step to remove plastics and contaminants. Materials enter through pipelines or conveyors for smooth delivery. Efficient feeding keeps energy crops and food-processing wastes decomposing steadily, boosting biogas production from renewable sources.

Digester tank

The digester tank is an airtight chamber. It holds biomass, like food waste and manure, for anaerobic digestion. Inside, microbes break down organic material without oxygen. This process produces biogas, mainly methane and carbon dioxide, as a renewable energy source.

Stainless steel tanks resist hydrogen sulphide corrosion. They can operate at high temperatures, up to 56°C. This durability allows them to last decades with proper maintenance. By capturing gas instead of letting it escape into the air, these tanks help reduce greenhouse gas emissions and combat climate change.

Digester mixing system

A good mixing system keeps the digester tank operating smoothly. It stirs feedstock to spread heat evenly, which speeds up fermentation. Without proper mixing, cold spots might form and slow biogas production.

Microbes stay active when heat is consistent throughout the tank. Agitation also prevents solid layers from forming on top or settling at the bottom. This boosts gas output and cuts downtime caused by clogs or uneven heating.

Gas storage holder

The gas storage holder collects biogas from the fermentation process. It safely stores the generated gas, acting like a giant balloon. This stored biogas becomes useful during times of energy demand, such as in cold winters when renewable energy might be scarce.

Made of robust material, it prevents leaks and contamination. Stored biogas can then be used for power generation, reducing dependence on fossil fuels. Systems using this holder help cut carbon footprints and support waste management goals efficiently.

Process Operation Data Collection Monitoring and Control

Biogas plants rely on precise monitoring for smooth operation. Sensors track temperature, pressure, and methane levels inside the digester tank. Data collection tools analyse feedstock input rates to prevent issues like overloading or underfeeding.

Operators adjust processes based on this information, improving efficiency.

Control systems help manage anaerobic digestion and biogas production in real-time. Automated alerts detect events such as insufficient alkalinity in the substrate or drops in gas quality. These systems reduce waste while increasing renewable natural gas output.

Accurate data contributes to high methane to carbon conversion rates boosting the digester methane/ biogas yield.

Digestate fertilizer production

Residual digestate is rich in nutrients like nitrogen phosphorus and potassium. It works as a natural, sustainable alternative to synthetic fertilisers. Farmers can use it to improve soil health and boost crop yields.

The process supports a circular economy by recycling waste into value. Digestate also lowers greenhouse gas emissions tied to chemical fertiliser production. Agriculture benefits from this renewable resource while promoting waste-to-energy goals and protecting the environment.

Applications of Biogas

Biogas powers homes, vehicles, and industries. Many use it to generate electricity, feeding renewable energy into the grid. Heat produced from biogas plants dries wood or agricultural produce, cutting reliance on fossil fuels.

In 2019 alone, about 132,000 digesters globally supported clean energy efforts.

Upgraded biogas produces biomethane for compressed natural gas (CNG) and liquefied natural gas (LNG). CNG fuels cars; LNG drives heavy goods vehicles and ships. This shift slashes transport emissions while offering a renewable fuel standard alternative.

Even enriched CO2 captured from upgrading replaces fossil CO2 in the non-food industries or dry ice production—a clever way to cut waste further!

Conclusion to “How Does A Biogas Plant Work?”

A biogas plant turns waste into power and fertiliser. It’s a smart way to handle trash while cutting down on pollution and fossil fuels. These systems use natural processes to make clean energy, showing how we can reuse what we throw away.

With better technology, they could become cheaper and even more efficient in future. Cleaner air, less waste—everyone wins!

FAQs for How Does A Biogas Plant Work?

1. How does a biogas plant work?

A biogas plant works by breaking down organic waste like food scraps, animal manure, or wastewater in an oxygen-free tank. This process produces methane gas, which can be combusted to generate electricity or heat.

2. What are the main sources of energy for a biogas plant?

Biogas plants use renewable raw materials such as agricultural waste, landfill gas, and sewage from wastewater treatment plants (WWTP) as their primary energy sources.

3. Are biogas plants profitable?

Yes, they can be! Biogas systems often reduce reliance on synthetic fertilisers and fossil fuels while generating electricity and income through feed-in tariffs or selling surplus power back to the grid.

4. How does a biogas engine work?

A biogas engine burns the gaseous fuel created by anaerobic digestion to produce mechanical energy. This is then converted into electricity or used for cogeneration—producing both power and heat at once.

5. Can decomposed material from a biogas plant be reused?

Absolutely! The leftover material can be composted into high-quality fertiliser or even processed into animal feed in some cases, reducing waste further.

6. Is using bioenergy helpful for decarbonisation efforts?

Yes, it is! Bioenergy from wastes-to-power projects helps cut greenhouse gases by replacing fossil fuels with renewables like syngas or bioethanol derived from thermal gasification processes.