You may have asked yourself, “What is an anaerobic digester?” Maybe you run a treatment plant or manage food waste at your facility. Each week, bins fill up with organic materials, and you need a better way than sending it all to a landfill.

If energy costs keep rising and regulations get tighter, you are not alone.

Here’s one quick fact: Anaerobic digesters use bacteria to break down biodegradable material without using oxygen. They turn waste like sewage sludge and food scraps into biogas and nutrient-rich digestate. 1

This blog will decode how anaerobic digestion works in simple terms. You’ll see how these systems create renewable natural gas and cut greenhouse gases. By the end, solving the puzzle of waste management might feel much easier. 3

Curious about biogas? Read on!

Key Takeaways

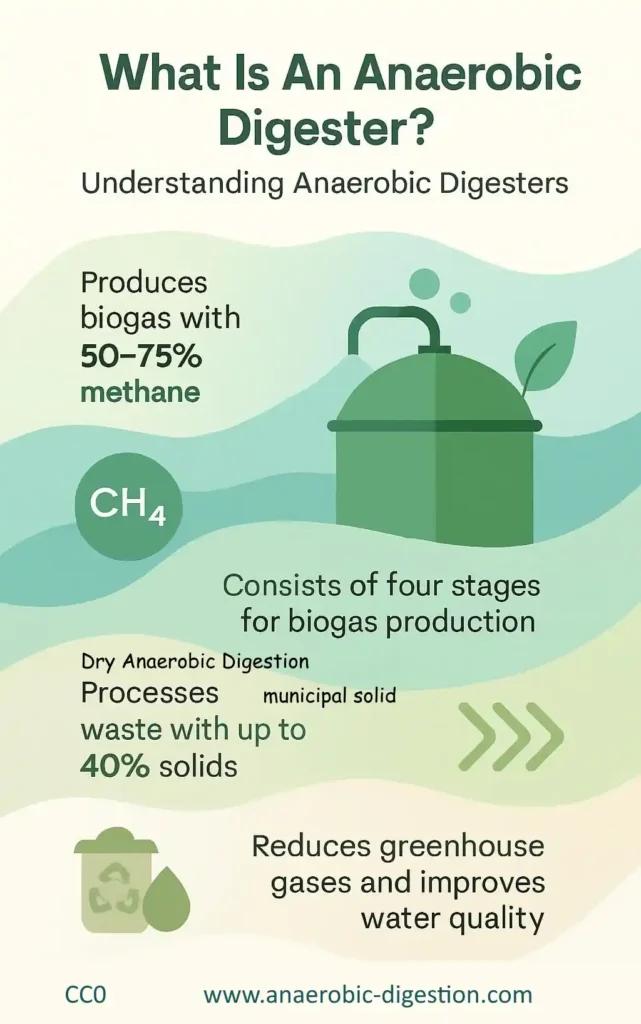

- Anaerobic digesters are sealed systems that break down organic waste, such as food scraps and sewage sludge, without oxygen using bacteria. These systems produce biogas (containing 50–75% methane) and nutrient-rich digestate, which can be used to generate electricity or fertilise soils.13

- The anaerobic digestion process follows four main stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis. Each stage involves different groups of microorganisms working together to convert complex materials into simpler gases and compounds essential for biogas production.267

- Different types of anaerobic digesters exist—including complete mix, plug flow, covered lagoon, fixed film reactors, dry anaerobic units for municipal waste with up to 40% total solids,10 upflow sludge blanket reactors for wastewater,11 and even small home digesters that can provide enough cooking gas for daily use.

- Biogas from these systems may be upgraded into renewable natural gas (RNG), offering a cleaner fuel alternative while reducing greenhouse gases like hydrogen sulphide in landfills. Digestate left after processing acts as a high-quality organic fertiliser recognised in sustainable agriculture practices.312

- Facilities worldwide use anaerobic digestion to treat both solid waste and wastewater efficiently. This approach helps lower Biological Oxygen Demand (BOD) and Chemical Oxygen Demand (COD), improves water quality,13 cuts energy costs through onsite power generation—and supports climate goals by capturing carbon emissions.

What Is an Anaerobic Digester?

Anaerobic digesters act as giant sealed vessels that break down organic waste, such as animal manure, energy crops, food leftovers, and biosolids from sewage treatment plants. The process happens without oxygen. 2 Inside these reactors, bacteria chew through organics like crop residues and fats in complete darkness. This “eat-in-the-dark” show produces two main goods: biogas (about 50-75% methane with carbon dioxide and a touch of hydrogen sulphide) and a leftover called digestate. 1 Biogas fuels engines or generates electricity at biogas plants; digestate gets spread on soils as an organic fertiliser or used in composted products.

Operators load each digester with items often dumped in landfills—municipal waste, household scraps, industrial effluents—and even sludgy messes from wastewater treatment facilities.

Some units run warm (“mesophilic”), some hot (“thermophilic”). Each system manages its own retention time to keep gas production steady day after day.

Old manure doesn’t just disappear; inside a digester it sings for its supper—giving gas for our grids.

These systems depend on lively bacterial communities to power the entire anaerobic digestion plant. Up next is how this biological orchestra actually works behind closed doors.

How Does Anaerobic Digestion Work?

Anaerobic digesters break down organic matter without oxygen using bacteria. Microbes convert waste like sewage sludge and food scraps into methane-rich gas and nutrient-filled residues.

Biological process overview

Bacteria break down organic matter such as sewage sludge, municipal solid waste, and household waste without oxygen. 3 This process takes place inside sealed biogas systems and sequencing batch reactors.

Microorganisms eat carbohydrates, proteins, and fats in a series of steps that produce methane (CH4), carbon dioxide (CO2), water vapour, hydrogen sulphide, and traces of nitrogen gas.

Biogas production reaches 50 to 75 percent methane content during this breakdown. 3

Inside digesters like upflow anaerobic sludge blanket reactors or fixed film units, acidogenic bacteria convert complex compounds to simpler forms. Acetogens handle the next step before methanogenic organisms turn remaining material into biomethane.

Digestate is collected at the end as a rich fertiliser full of phosphorus; operators often use it on fields or sell it for composting projects. The action of these microbes does far more than just shrink landfill volumes; they help control carbon emissions by keeping large amounts of methane sequestered from the open air.

Every stage relies on different groups—acidogenic bacteria start things off while acetogenic and methanogenic microbes finish the work. Each group survives best under certain conditions so temperature control matters greatly in modern anaerobic wastewater treatments like mechanical biological treatment plants or autogenerative high-pressure digestion setups.

These tiny workers operate constantly below ground level with little fanfare but deliver major results for both industrial wastewater facilities and rural co-fermentation sites alike.

Microbes play key roles all through the process—next comes their direct impact on digestion rates and gas yields.

Role of microorganisms

Microorganisms play a vital role in anaerobic digestion. They break down complex organic materials into simpler forms. Fermentative, syntrophic, acetogenic, and methanogenic microorganisms all contribute to this process.

These tiny powerhouses transform substances through several key stages like hydrolysis and methanogenesis.

During hydrolysis, bacteria convert tough materials into soluble monomers. This step sets the stage for other microorganisms to take over. In the final phase of methanogenesis, specific bacteria turn acetic acid, hydrogen, and carbon dioxide into methane gas.

Optimal inoculum-to-substrate ratios can improve methane production; achieving this ratio correctly increases efficiency in waste treatment facilities significantly. 4

Key Stages of Anaerobic Digestion

Anaerobic digestion follows four main stages. In the first stage, hydrolysis breaks down complex organic matter into simpler compounds. Next, acidogenesis converts these compounds into acids and hydrogen gas.

The acetogenesis stage further processes these acids to produce acetic acid. Finally, methanogenesis generates methane from the acetic acid and hydrogen gas produced earlier. Understanding these stages helps waste management pros optimise their processes efficiently.

Hydrolysis

Hydrolysis kicks off the anaerobic digestion process. This step breaks down complex organic polymers into soluble forms. A range of enzymes leads this action, working hard to convert materials like fats and carbohydrates into digestible compounds.

Efficient hydrolysis sparks the entire process of transforming waste. 2

Small digesters often show higher enzymatic activity than larger ones. This increase in hydrolytic rates helps speed up the breakdown of valuable feedstocks. Using cascade reactors also enhances specific hydrolysis rates, making them effective for large-scale operations.

Keeping an eye on these factors ensures a smoother transition to the next stages: acidogenesis and beyond. 5

Waste management professionals need to understand that this step is rate-limiting in anaerobic digestion. If it falters, subsequent processes will struggle as well. Hydrolysis serves as both a foundation and a driving force in treating municipal wastewater effectively while managing organic waste with precision.

Acidogenesis

Acidogenesis follows hydrolysis in the anaerobic digestion process. During this stage, microorganisms convert sugars and amino acids into organic acids, carbon dioxide, hydrogen gas, and ammonia.

This phase primarily uses acetogenic bacteria to break down complex organic compounds into simpler ones. These transformations are essential for biogas production. 6

Temperature plays an important role in acidogenesis. It influences how efficiently microorganisms operate. The feedstock composition also matters; different materials can yield varying amounts of acids and gases.

Factors like microbial communities affect the efficiency of this biological process too.

In this phase, organic acids become simpler compounds that benefit further stages of digestion. The interactions among denitrifying bacteria help improve nutrient recovery from wastewater treatment systems as well.

Acidogenesis is vital for producing quality biogas while managing sewage sludge effectively.

Acetogenesis

Acetogenesis follows acidogenesis in the anaerobic digestion process. During this stage, bacteria convert short-chain fatty acids into acetic acid, carbon dioxide, and hydrogen. 6 This conversion is essential because it prepares substrates for methanogenic bacteria to produce methane.

Effective collaboration between these two types of microorganisms makes this step seamless.

Bacteria that thrive at mesophilic temperatures play a vital role in acetogenesis. They work best within an optimal pH range; hence, maintaining this balance enhances production rates.

If feedstocks like sewage sludge include long-chain fatty acids or lignocellulosic materials, acetogens quickly break them down into simpler compounds. Combining different organic materials during codigestion can improve efficiency and yield in waste management systems.

Methanogenesis

Methanogenesis forms the final stage of anaerobic digestion. During this process, microorganisms convert organic material into biogas, primarily methane. The two main pathways for this conversion are acetoclastic and hydrogenotrophic methanogenesis.

Acetoclastic methanogens break down acetate, while hydrogenotrophic ones use hydrogen to produce methane.

Achieving optimal conditions boosts methanogenesis efficiency. Maintaining the right pH levels is crucial; an acidic environment suits mesophiles while thermophiles thrive in more alkaline settings.

High free ammonia nitrogen (FAN) levels also favour hydrogenotrophic methanogenesis at thermophilic temperatures. Effective management improves both biogas productivity and quality, making it easier for waste management professionals to recycle resources efficiently. 7

Main Types of Anaerobic Digesters

Anaerobic digesters come in various shapes and forms. Each type suits different needs and setups, from complete mix digesters that churn everything together to plug flow digesters where materials move like a train on tracks.

Complete mix digesters

Complete mix digesters operate as efficient systems for anaerobic digestion. They heat and mix organic waste, like manure, with helpful microorganisms. This process increases biogas production and reduces unwanted odours.

These digesters work best with a solids content of around 3-6%. 8

The digester maintains liquid retention times between 20 to 30 days. Consistent mixing is essential; it promotes uniform microbial activity across the system. Families of microorganisms break down complex materials into simpler compounds through different stages of anaerobic degradation.

The result? A rich blend that generates valuable outputs.

These systems offer great advantages for waste management professionals. They help in treating sewage sludge effectively while preventing solid waste disposal issues at landfills. Complete mix digesters contribute to carbon-neutral solutions by promoting renewable natural gas production from biogas, making them key players in sustainable practices today.

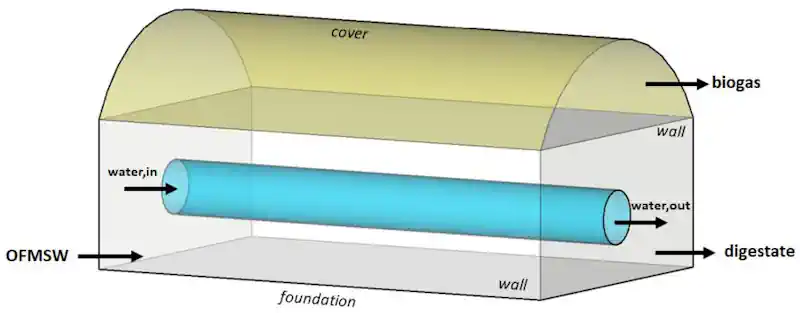

Plug flow digesters

Plug flow digesters handle organic waste efficiently. In these systems, manure flows as a ‘plug' without mechanical mixing. This design helps keep the total solids content between 10% to 20%. 8 The retention time usually lasts around 15 to 20 days.

Microorganisms work diligently in this setting, breaking down waste anaerobically. They convert materials into biogas and digestate at different stages of digestion. These systems prevent particle settlement, ensuring continuous movement and effective remediation of sewage sludge treatment processes.

Waste management professionals can count on plug flow digesters for their efficiency and reliability in handling organic materials effectively.

“Plug Flow Reactor for the Anaerobic Digestion Process …” from www.mdpi.com and used with no modifications.

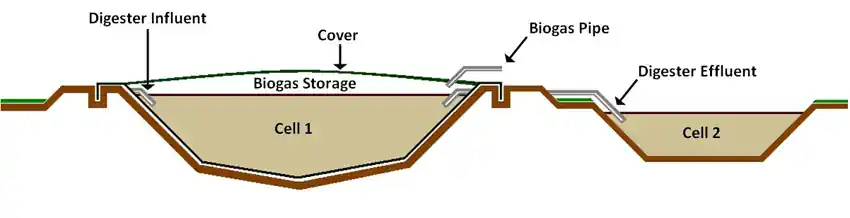

Covered lagoon digesters

Covered lagoon digesters capture biogas from the breakdown of organic materials under a membrane. These systems operate without oxygen, converting biodegradable waste into valuable biogas.

Waste management professionals find them useful for treating large volumes of organic matter. Co-digestion in these digesters boosts biogas yields by combining different types of feedstock.

The Carbon: Nitrogen (C: N) ratio plays a key role in supporting microbial growth. 9

The solid byproduct, known as digestate, can come in fibrous or liquid forms; it serves to improve soil quality and provides nutrient-rich organic fertiliser. Biogas produced can be upgraded to biomethane for use as compressed natural gas or injection into natural gas grids.

With covered lagoon digesters, you enhance wastewater treatment capacity while contributing significantly to green energy sources. Let’s explore how anaerobic digestion works next!

“Covered Lagoon | Wisconsin Anaerobic …” from biogasdecisiontree.wordpress.com and used with no modifications.

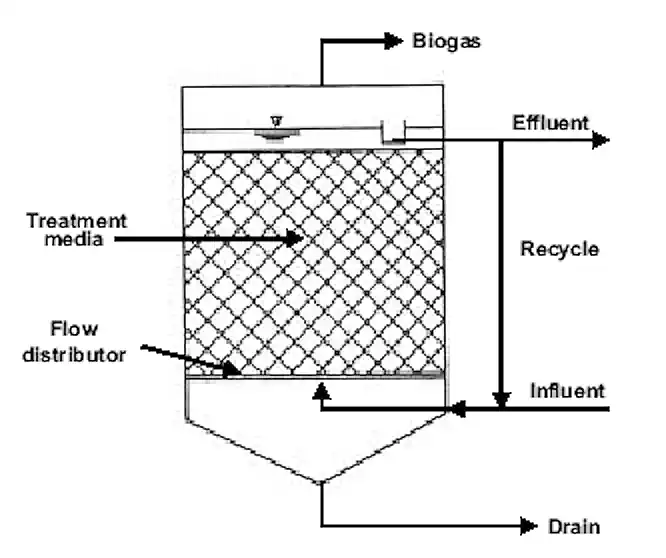

Fixed film digesters

Fixed film digesters make a solid choice for anaerobic digestion. They use media like wood chips or plastic rings, allowing microorganisms to thrive. These tiny workers cling to the surfaces and break down organic waste effectively. 8

The effluent typically recycles for steady upward flow within these systems. This constant movement helps maintain optimal conditions for bacterial activity. With influent manure concentrations at 1-5% total solids, fixed film digesters can handle various organic materials efficiently.

Solid separators play a crucial role in preventing media clogging. They ensure that inert materials do not block the system, keeping everything running smoothly. These digesters provide excellent performance, making them popular among waste management professionals looking for reliable solutions in wastewater treatment and resource recovery facilities.

“Fixed Film Digester Diagram …” from www.researchgate.net and used with no modifications.

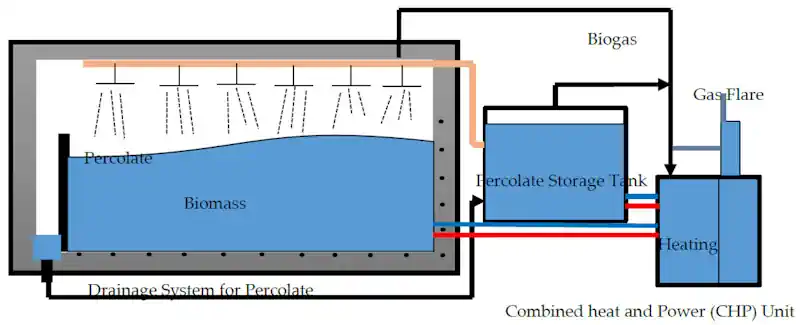

Dry anaerobic digestion of municipal solid waste

Dry anaerobic digestion focuses on using municipal solid waste (MSW) to produce valuable resources. This method operates with a high total solid content of 15-40%. 10 It thrives in environments where moisture is low, setting the stage for effective decomposition.

The process relies on specific microorganisms that break down waste without oxygen. These microbes help convert organic material into biogas and digestate.

Co-digestion plays a crucial role here. Mixing different types of organic materials can reduce volatile fatty acid accumulation, which is vital for maintaining balance during digestion. 10 Conductive materials also boost microbial activity; they enhance the breakdown efficiency of waste compounds. Waste management professionals often find that this approach leads to a higher volumetric methane yield while minimising digester size.

Using dry anaerobic digestion offers multiple benefits beyond energy production. Facilities practising this method showcase their ability to tackle landfill gas emissions while creating nutrient-rich organic fertiliser from digestate.

This strategy aligns well with circular economy principles by turning waste back into useful resources, thus promoting resource use efficiency and contributing to climate change mitigation efforts through carbon capture strategies like CCS.

“Dry Anaerobic Digestion Technologies …” from www.mdpi.com and used with no modifications.

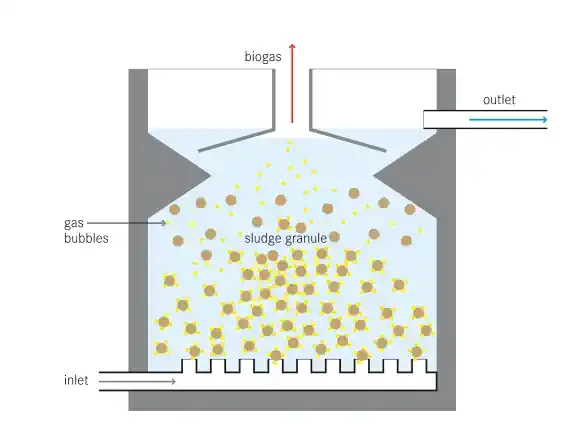

Upflow sludge blanket reactor digesters for wastewater

Transitioning from dry anaerobic digestion of municipal solid waste, let's explore upflow sludge blanket reactor digesters for wastewater. These digesters function efficiently with high-rate anaerobic digestion systems.

They require a reduced hydraulic retention time, making them quick and effective. 11

Granular sludge plays a key role in these reactors, allowing for efficient sludge-effluent separation. This feature enhances biogas production while keeping operational costs down, always a win in the field of waste management.

Professionals often co-digest various feedstocks to boost biogas yields and improve process stability. With proper operation skills, you can tap into their full potential and support your wastewater treatment goals effectively.

“Upflow anaerobic sludge blanket …” from en.wikipedia.org and used with no modifications.

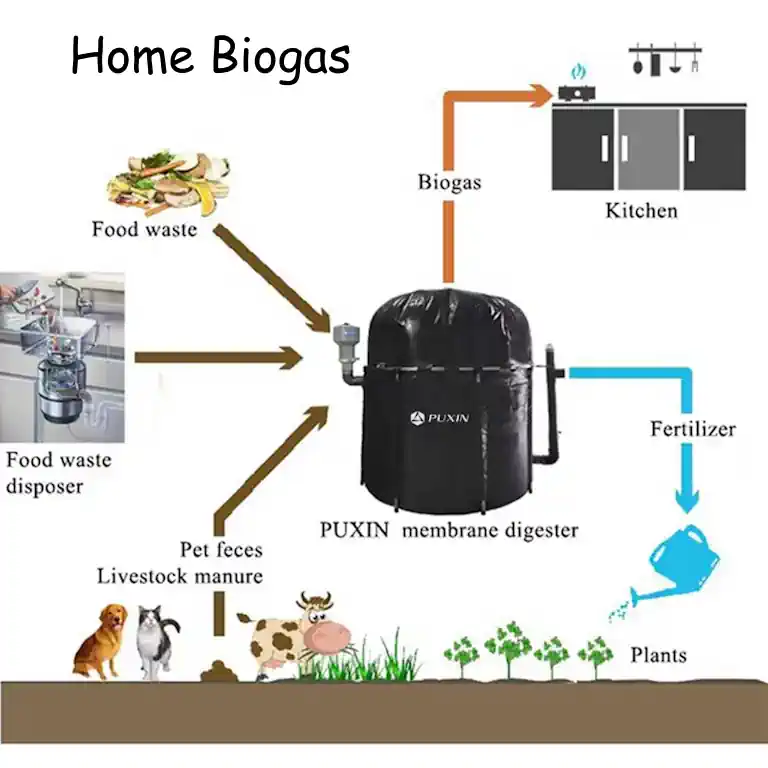

Home digesters

Anaerobic digesters at home offer a practical solution for managing organic waste. These systems can handle kitchen scraps and fallen leaves, turning them into useful biogas for cooking or heating.

A standard 2 cubic metre biodigester produces around 2 cubic metres of cooking gas. This amount is roughly equivalent to 1 kg of liquefied petroleum gas (LPG). 9

The leftover material from digestion, known as digestate, serves as an excellent soil conditioner or organic manure. It comes in various forms, including fibrous materials and liquid sludge.

Using this byproduct improves soil health while reducing the need for synthetic fertilisers. Home digesters play a significant role in resource recovery and support sustainable practices within communities.

“Amazon.com : PUXIN Home Biogas Digester …” from us.amazon.com and used with no modifications.

Outputs of Anaerobic Digesters

Anaerobic digesters produce biogas and digestate. Biogas mainly contains methane, which powers engines or heats homes. The remaining digestate serves as a nutrient-rich fertiliser.

Farmers can enhance soil health using this organic fertiliser. Curious about how these outputs benefit waste management? Keep reading!

Biogas

Biogas consists of 50-75% methane. 3 This gas forms during anaerobic digestion, a process that breaks down organic material without oxygen. Waste management professionals tap into biogas for various applications, including heating and electricity generation.

With the right technology, organisations convert it into vehicle fuel as well.

Purifying biogas produces renewable natural gas (RNG). 12 RNG serves as a cleaner alternative to fossil fuels. Co-digestion of different feedstocks significantly boosts biogas production, making operations more efficient.

It’s not uncommon to see local facilities embracing this strategy to enhance output while managing waste effectively.

Biogas also contributes to environmental benefits. Using it reduces greenhouse gases like hydrogen sulfide and nitrogen dioxide in landfills. Facilities that harness this energy source improve carbon neutrality efforts across communities; they mitigate climate change impacts daily by capturing carbon emissions through effective practices in waste resource recovery.

Digestate

Digestate is the nutrient-rich residual material left over after anaerobic digestion. It serves multiple purposes in agriculture. Waste management professionals often see it as a valuable resource.

This material can help improve soil quality when used as fertiliser, compost, or soil improver. 3

Many farmers use digestate to reduce costs and even generate revenue from their waste streams. The organic matter within promotes healthy crops and contributes to emission-neutral operations on farms.

With such benefits, it's clear that digestate plays a crucial role in sustainable farming practices while supporting water resource recovery efforts, too.

Applications of Anaerobic Digesters

Anaerobic digesters play a key role in waste treatment. They convert organic matter into biogas and digestate. This process helps with energy generation, making it a valuable tool for many facilities.

From power plants to farms, these systems offer practical solutions. Imagine turning kitchen scraps into clean energy! If you’re curious about how they can benefit your projects, stick around for more information.

Waste and wastewater treatment

Waste treatment plays a vital role in maintaining our environment. Through anaerobic digestion, facilities convert organic waste into biogas. This process significantly reduces pollutants in water while generating energy. 13 Facilities can lower Biological Oxygen Demand (BOD) and Chemical Oxygen Demand (COD). Both of these measures help make water cleaner and safer.

In wastewater treatment, bacteria thrive in low-oxygen environments to break down materials. These microorganisms perform crucial roles during the stages of digestion, especially methanogenesis, where they produce biogas rich in methane.

This biogas can power homes and businesses or fuel vehicles.

Anaerobic digesters handle various feedstocks effectively. They accept everything from food scraps to agricultural waste. Wastewater treatment plants even utilise Upflow Sludge Blanket (UASB) reactors for efficient breakdown processes; these systems promote sedimentation and denitrification efficiently.

The digestate produced also serves as high-quality organic fertiliser for farms, closing the loop on nutrient cycles within communities.

Power generation

Anaerobic digestion plays a vital role in power generation. Many facilities harness biogas produced in this process to generate electricity. 12 This biogas typically contains between 50-75% methane, making it an efficient fuel source.

Energy producers can combust this gas to create power, which helps reduce electricity costs.

In addition to direct electricity generation, purified biogas can be converted into renewable natural gas (RNG). Businesses use RNG for heating and cooling systems or inject it into the gas grid.

Using anaerobic digesters not only produces energy but also provides organic fertiliser through the digestate output. This creates a circular economy model that makes good use of resources while addressing waste issues effectively.

Investing in anaerobic digestion technology offers multiple benefits. 3 Facilities contribute to greenhouse gas reduction by using a sustainable resource for energy instead of fossil fuels.

Generating clean energy helps combat climate change while providing economic advantages such as carbon credit payments from schemes like the EU ETS.

Fertiliser production

Anaerobic digesters play a crucial role in fertiliser production. They turn organic waste into digestate, which serves as an excellent organic fertiliser. This process boosts soil fertility and cuts down the need for synthetic fertilisers.

Farmers benefit from using digestate, as it enriches their crops while promoting sustainable farming practices. 14

Digestate also supports the circular economy by recycling nutrients back into the soil. Waste management professionals can see this firsthand at many facilities around the country.

The output doesn’t just help farms; it also reduces landfill waste and lowers greenhouse gas emissions. It’s win-win for both agriculture and our environment!

Renewable natural gas (RNG), also known as Biomethane

Renewable natural gas (RNG) sits at the intersection of waste management and energy innovation. This clean fuel emerges from biogas after upgrading it to pipeline-quality biomethane. 15 Wastewater treatment facilities, agricultural operations, and landfills often generate this resource through anaerobic digestion.

Used in natural gas vehicles, RNG proves versatile for various applications. It can serve as a direct replacement for conventional natural gas, which makes it a great option for industries aiming to reduce their carbon footprint. 15 Greenhouse gases from organic waste turn into valuable resources while improving air quality. Energy cost savings and carbon credit payments make RNG an economically wise choice, too.

Environmental and Economic Benefits

Anaerobic digesters offer great perks for businesses and the environment. They help manage waste while cutting costs and reducing harmful emissions.

Organic Waste Management for Sustainable Regenerative Farms

Organic waste management plays a vital role in sustainable regenerative farms. These farms convert organic materials into valuable resources. Anaerobic digestion transforms this waste, producing biogas for energy and digestate as nutrient-rich fertiliser.

This process supports the circular economy by turning waste into useful products. 16

Farmers benefit from reduced greenhouse gas emissions through anaerobic digestion. They turn food scraps, animal manure, and crop residues into energy. Methane generation during digestions reduces reliance on fossil fuels, providing clean power while decreasing pollution.

In my experience working with various facilities, effective organic waste management increases soil health significantly. Farmers who use digestate often report improved crop yields; thus boosting their productivity sustainably.

Embracing these practices fosters resilience within farming systems while promoting responsible resource recovery and environmental stewardship.

Greenhouse gas reduction

Anaerobic digesters play a crucial role in reducing greenhouse gas emissions. 17 They break down livestock manure, which is a significant source of methane. This process cuts methane output considerably, assisting in the fight against climate change effectively.

Incorporating these systems into federal policies enhances their potential impact on greenhouse gas reduction.

Waste management professionals focusing on sustainability can leverage the benefits of anaerobic digestion for resource use efficiency and renewable energy production. Digesters convert waste into biogas, while also producing organic fertiliser as a valuable by-product.

The positive effects extend beyond individual operations; they contribute to the broader goal of lowering overall emissions in our environment.

Resource use efficiency via the circular economy

The circular economy enhances resource use efficiency. It minimises waste and maximises recovery of valuable materials. Anaerobic digesters play a key role in this process by treating organic waste, such as food scraps and agricultural remnants.

These digesters convert that waste into biogas and organic fertilisers. 18

This shift assists with energy generation and addresses environmental challenges, such as microplastic biodegradation. 18 Waste management professionals recognise genuine value in turning discarded items into resources.

The outcome? Greater sustainability and reduced operational costs for facilities focused on the circular economy.

Energy cost savings

Resource use efficiency via the circular economy directly leads to energy cost savings. Anaerobic digesters produce biogas, which serves as an economical source for heating and electricity generation. 12 This process reduces reliance on conventional fuels. As a result, many facilities enjoy significant long-term savings.

Biogas can power machinery or heat buildings. Facilities save money that would otherwise go to purchasing fossil fuels. Some operators even inject renewable natural gas into existing networks; this practice helps reduce costs further and contributes positively to environmental goals.

The digestate produced acts as an organic fertiliser too, cutting down commercial fertiliser expenses. Waste management professionals find these benefits crucial in their operations; they help improve bottom lines while advancing sustainability in waste treatment processes.

Climate change mitigation, including carbon capture (CCS)

Climate change poses a significant threat to our planet. Carbon capture and storage (CCS) technologies offer a way to tackle this problem directly. These solutions capture carbon dioxide emissions before they enter the atmosphere, helping reduce greenhouse gas levels.

Biogenic CO2 has a lower climate impact than fossil fuels, making its management crucial for long-term sustainability. 19

Waste management professionals play a key role in implementing CCS practices. They can collect biogenic waste materials, process them in anaerobic digesters, and then use CCS technologies effectively.

This approach reduces greenhouse gases and also helps companies earn carbon credits by lowering their emissions. By sharing insights and experiences from successful projects, waste managers can encourage others to adopt these methods.

As we consider further benefits of anaerobic digestion, it becomes clear that addressing challenges such as operational costs and feedstock contamination remains essential for success in this field. 17

Carbon credit payments (e.g. EU ETS)

Carbon credit payments attract interest in the waste management industry. The European Union Emissions Trading System (EU ETS) offers financial incentives for reducing greenhouse gas emissions, including those from anaerobic digestion systems. 20 Companies that successfully reduce their carbon output receive Verified Carbon Units (VCUs). Each unit translates into potential revenue.

These credits arise from compliance and voluntary markets, assisting businesses with environmental regulations while enhancing profits. Firms can earn cash by participating in carbon credit schemes.

This strategy supports sustainability and promotes a circular economy within organic waste management practices.

Challenges in Anaerobic Digestion

Anaerobic digestion poses several challenges. Operating this process requires specific skills. Contaminated feedstocks complicate matters, as they can contain unwanted materials like metals and plastics.

These contaminants can hinder efficiency and increase costs. Proper management is crucial to running a successful digester. Want to learn more about overcoming these obstacles?

Operational skills needed to operate a complex biological process

Operating an anaerobic digester requires specific skills. Waste management professionals must understand complex biological processes like hydrolysis, acidogenesis, acetogenesis, and methanogenesis. 21 Each of these stages involves unique conditions that affect microbial health and overall digestion efficiency. For instance, maintaining optimal temperature and pH levels is crucial to ensure active microorganisms thrive.

Skills also include monitoring key parameters such as organic loading rate (OLR) and hydraulic retention time (HRT). A professional might find themselves checking the carbon/nitrogen ratio regularly to promote a balanced environment for microbes.

Mismanagement can lead to contamination from inert materials or plastics in feedstocks, disrupting the delicate balance needed for effective digestion.

Experience in running digesters shows that operational costs can rise if you lack proper training or knowledge about process stability. Understanding these dynamics ensures successful digestion and maximises outputs like biogas and digestate.

Balancing environmental factors becomes essential for sustainable waste treatment solutions too; it directly impacts energy generation and resource recovery at water resource recovery facilities.

Contamination of feedstocks (inert materials to metals and plastics/ microplastics)

Operational skills needed to run anaerobic digesters play a significant role in managing contamination of feedstocks. Inert materials, metals, and plastics can infiltrate the digestion process.

These contaminants harm biogas production and disrupt microbial dynamics. 23

Microplastics often find their way into digesters through sewage sludge and organic waste. This mishap affects both the performance of the digester and the quality of the end product, known as digestate.

Advanced separation methods like magnetic micro-submarines help mitigate this issue by effectively removing contaminants before they enter the digester. 22

The long-term effects of microplastics in digestate require more research for better understanding. Waste management professionals must stay alert to these challenges; any oversight can result in significant operational setbacks and increased costs down the line. 22

Operational costs

Anaerobic digestion can be costly to run, especially with high solid anaerobic digestion (HSAD). 24 The expenses rise when methane production rates stay low. Factors such as insufficient moisture and poor mixing contribute to this issue.

Operators face challenges in maintaining the right conditions for optimal production.

High operational costs often stem from needing skilled staff to manage these complex processes effectively. Contamination of feedstocks also adds another layer of difficulty. Inert materials, plastics, and microplastics complicate matters further and may increase costs even more.

Finding solutions is vital for efficient waste management practices that maximise outputs while keeping expenses in check.

Conclusion

Understanding anaerobic digesters opens a window to smarter waste management. These remarkable systems turn organic waste into valuable resources like biogas and digestate. Wastewater treatment facilities, farms, and even homes can benefit from this technology.

By reducing landfill use, these digesters help protect our environment while producing renewable energy. What’s not to love about turning trash into treasure?

FAQs

1. What is an anaerobic digester and how does it work?

An anaerobic digester uses bacteria to break down organic matter, like food waste or manure, without oxygen. It produces biogas that can be combusted for energy. The process also creates organic fertiliser and water vapor as by-products.

2. Can anaerobic digesters help with water resource recovery?

Yes, many water treatment facilities use these units to treat sewage sludge. They speed up the breakdown of solids using cofermentation methods and improve kinetics for better nitrite removal.

3. Do digesters play a role in making bioplastics?

Absolutely, some systems harvest compounds from the digestion process, which are then used to make bioplastics instead of traditional plastics made from oil.

4. How do chemicals like NO3 − affect digestion inside the tank?

Chemicals such as NO3

− (nitrate) and nitrite influence bacterial activity during processing. Managing their levels helps maintain efficient gas production and keeps the system running smoothly; think of it as keeping all ducks in a row so nothing goes pear-shaped!

References

- ^ https://www.biogen.co.uk/anaerobic-digestion/what-is-anaerobic-digestion/

- ^ https://en.wikipedia.org/wiki/Anaerobic_digestion

- ^ https://www.renergon-biogas.com/en/anaerobic-digestion-explained/

- ^ https://pmc.ncbi.nlm.nih.gov/articles/PMC3950365/

- ^ https://www.sciencedirect.com/science/article/pii/S0043135421005960

- ^ https://www.tn.gov/environment/program-areas/sw-mm-organics/anaerobic-digestion.html

- ^ https://www.sciencedirect.com/science/article/pii/S1075996424001082?dgcid=rss_sd_all

- ^ https://farm-energy.extension.org/types-of-anaerobic-digesters/

- ^ https://www.epa.gov/anaerobic-digestion/types-anaerobic-digesters

- ^ https://www.sciencedirect.com/science/article/pii/S1364032123000643

- ^ https://pmc.ncbi.nlm.nih.gov/articles/PMC7355771/

- ^ https://www.epa.gov/agstar/how-does-anaerobic-digestion-work

- ^ https://anaerobic-digestion.com/anaerobic-digestion-wastewater-treatment/

- ^ https://www.sciencedirect.com/science/article/pii/S0961953423002908

- ^ https://afdc.energy.gov/fuels/natural-gas-renewable

- ^ https://link.springer.com/article/10.1007/s10311-024-01789-1

- ^ https://pmc.ncbi.nlm.nih.gov/articles/PMC3155279/

- ^ https://www.awa.asn.au/resources/latest-news/technology/trends/anaerobic-digestion-circular-economy

- ^ https://anaerobic-digestion.com/biogenic-co2-from-anaerobic-digestion/

- ^ https://www.the-innovation.org/data/article/energy/preview/pdf/XINNENERGY-2024-0101.pdf

- ^ https://www.degruyterbrill.com/document/doi/10.1515/psr-2021-0068/html?lang=en&srsltid=AfmBOoqpjQBoAFmRmcyDuNpk8v01pOEW-TVrfjZ6RgjiQCvKRku8Vwnr

- ^ https://pubmed.ncbi.nlm.nih.gov/39464825/

- ^ https://pollution.sustainability-directory.com/term/anaerobic-digestion-residue/

- ^ https://www.sciencedirect.com/science/article/pii/S235218641500036X