Increasingly Anaerobic Digestion Processes are being applied to treat Municipal Solid Waste (MSW), but how are they doing it? Biogas process are renowned for the production of biogas as a renewable energy source, and also for Waste Diversion.

Anaerobic Digestion Process First and Foremost Provides Organic Waste Diversion

“Waste diversion” in this context means the diversion of waste (especially organic waste) away from landfills.

Anaerobic Digestion of Municipal Solid Waste (MSW)

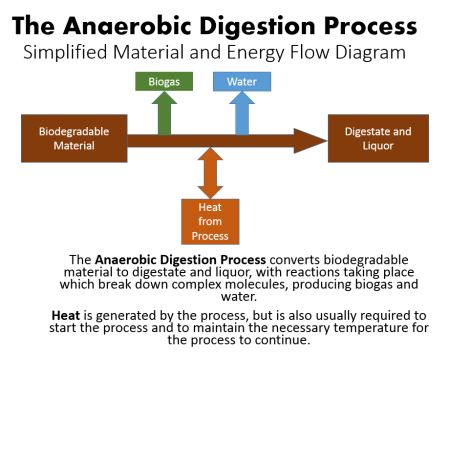

Anaerobic digestion (AD) is an increasingly popular waste management technology that processes organic matter found in Municipal Solid Waste (MSW). By breaking down waste in the absence of oxygen, anaerobic digestion produces biogas (a renewable energy source) and digestate, which can be used as fertilizer or soil conditioner. With the growing focus on sustainability, resource recovery, and reducing greenhouse gas emissions, anaerobic digestion offers municipalities and industries a greener alternative to traditional waste disposal methods like landfilling or incineration.

This article explores the core principles of anaerobic digestion, its relevance for managing MSW, and whether it is the right solution for your waste management challenges. We will dive into the different types of anaerobic digestion designs, the role of temperature and pH, and present comparison tables of various AD systems.

Key Takeaways

- What it is: Anaerobic digestion (AD) is a biological process that breaks down organic matter without oxygen, resulting in biogas and digestate.

- Why consider it: AD reduces landfill waste, cuts methane emissions, generates renewable energy, and creates nutrient-rich digestate for agricultural use.

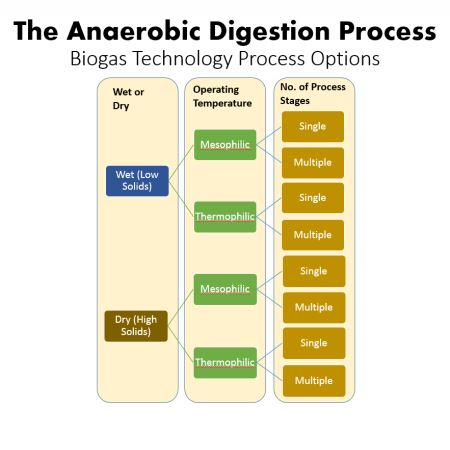

- Types of AD: There are several types of AD systems, categorized by process design, temperature ranges, and operational mode.

- pH and Temperature Importance: Temperature and pH significantly affect microbial activity and the efficiency of the AD process.

- Is it right for you: AD is ideal for waste streams rich in organic material, such as food waste, green waste, and other biodegradable materials.

What is Anaerobic Digestion (AD)?

Anaerobic digestion is a biological process where microorganisms break down organic matter (such as food waste, manure, or sewage) in the absence of oxygen. This process occurs naturally in environments like wetlands, and in engineered systems like anaerobic digesters.

The Products of Anaerobic Digestion

- Biogas: A mixture of methane (CH₄), carbon dioxide (CO₂), and small amounts of other gases. Biogas can be used to generate heat, electricity, or be upgraded to biomethane for use as a vehicle fuel.

- Digestate: A nutrient-rich slurry remaining after digestion. It can be separated into solid and liquid components and used as a fertilizer or soil amendment.

Is Anaerobic Digestion the Right Solution for Your Waste Management Problem?

Determining whether anaerobic digestion is suitable for your municipal solid waste (MSW) depends on several factors:

Waste Composition

AD is most effective for waste streams high in organic material. If your MSW contains a significant amount of biodegradable waste (food waste, green waste, paper, etc.), AD may be a viable solution.

However, if your waste stream is dominated by non-organic materials (plastics, metals, etc.), other waste management technologies like mechanical-biological treatment (MBT) or incineration might be better suited.

Sustainability Goals

AD aligns with sustainability goals by:

- Reducing methane emissions from landfills.

- Diverting organic waste from landfills or incinerators.

- Generating renewable energy from biogas.

- Producing organic fertilizer from digestate.

Economic Considerations

The economic feasibility of an AD plant depends on:

- Capital costs for construction.

- Operational costs for maintenance and labor.

- Revenue generation from biogas sales, digestate, or renewable energy credits.

- Gate fees or waste processing fees from municipalities or businesses.

For municipal authorities in nations where landfill taxes are high a strong financial incentive for anaerobic digestion lies in the avoidance of landfill tax. For the full benefit the output will need to pass all local regulations to be sold as a product and no longer classified as a waste.

How to Use Anaerobic Digestion for MSW Management

Successfully using anaerobic digestion for MSW requires proper design, waste sorting, and process management of the incoming residual waste (so called “black bag” waste):

- Waste Sorting and Pre-treatment: MSW must be pre-treated to remove contaminants like plastics, metals, and glass. Sorting systems can include mechanical, manual, or automated methods, including magnets, trommels, and eddy current separators.

- Feedstock Composition: The organic fraction of MSW should be rich in biodegradable material, including food waste, yard trimmings, and paper products.

- System Design and Type Selection: Choose an AD system that aligns with the composition and volume of your waste stream (covered below).

- Post-Digestion Processing: After digestion, the biogas can be upgraded for energy, and digestate can be dewatered and processed into compost or biofertilizer.

The Main Types of Anaerobic Digestion Process Designs

1. Wet Anaerobic Digestion

- Overview: In wet AD, the feedstock is mixed with water to form a slurry, which is easier to pump and process.

- Best For: Liquid-rich organic wastes such as food waste, sewage sludge, and manure.

- Advantages: Efficient mixing, easier biogas extraction.

- Challenges: Higher water consumption, potential for large quantities of liquid digestate.

2. Dry Anaerobic Digestion

- Overview: Dry AD processes waste with lower moisture content (20-40%).

- Best For: Solid organic wastes like municipal green waste, agricultural residues.

- Advantages: Lower water consumption, smaller digester footprint.

- Challenges: More difficult to mix and manage feedstock, may require specialized equipment.

3. Batch vs. Continuous Flow Systems

- Batch: In batch systems, waste is loaded into the digester and allowed to digest over time. The entire contents are then removed after digestion.

- Advantages: Simpler operation, minimal equipment.

- Disadvantages: Lower biogas yields, longer digestion periods.

- Continuous Flow: In continuous systems, waste is fed into the digester regularly, and digested material is removed continuously.

- Advantages: Consistent biogas production, more efficient operation.

- Disadvantages: More complex systems, higher operational costs.

4. Single-Stage vs. Multi-Stage Digesters

- Single-Stage: The entire digestion process occurs in a single tank.

- Advantages: Lower capital cost, simpler operation.

- Disadvantages: Less control over digestion phases, less efficient.

- Multi-Stage: Digestion occurs in multiple tanks, with each stage optimized for a specific microbial population or process.

- Advantages: Higher efficiency, greater control over the process.

- Disadvantages: More expensive and complex to operate.

Anaerobic Digestion Temperature Ranges

Temperature plays a crucial role in AD efficiency, influencing microbial activity and the rate of organic matter breakdown. There are three main temperature ranges for anaerobic digestion:

- Psychrophilic Range (0–20°C):

- Description: Digestion occurs at cooler temperatures.

- Advantages: Lower energy input for heating.

- Disadvantages: Slower digestion rates, longer retention times, lower biogas production.

- Mesophilic Range (20–45°C):

- Description: Most common temperature range for AD.

- Advantages: Moderate digestion rate, stable microbial activity, lower energy requirements than thermophilic systems.

- Disadvantages: Slower than thermophilic digestion.

- Thermophilic Range (45–70°C):

- Description: High-temperature digestion.

- Advantages: Faster digestion rates, pathogen reduction, higher biogas yields.

- Disadvantages: Higher energy demand for heating, more difficult to maintain microbial stability.

pH Aspects of AD Plant Design

The pH level within an anaerobic digester significantly impacts the survival and efficiency of the microbial communities responsible for biogas production. Maintaining the appropriate pH balance throughout the AD process is critical:

- Optimal pH Range: 6.5–7.5

- Methanogens, the microbes responsible for methane production, thrive in this neutral pH range.

- Acidogenesis Concerns: During the early stages of digestion (acidogenesis), volatile fatty acids (VFAs) are produced, which can lower the pH and inhibit methanogenesis if not properly managed.

- Buffering Agents: Alkaline substances like sodium bicarbonate, lime, or, in rare circumstances, ammonia can be added to the digester to neutralize excessive acidity.

Comparison of AD Systems for MSW

| AD System Type | Best For | Advantages | Disadvantages |

|---|---|---|---|

| Wet AD | Liquid-rich organic waste | Efficient mixing, biogas extraction | High water consumption |

| Dry AD | Solid organic waste | Low water use, compact footprint | More complex feedstock handling |

| Batch AD | Small-scale operations | Simpler operation, minimal equipment | Lower biogas yields, longer cycles |

| Continuous Flow AD | Large-scale operations | Consistent biogas production | Higher complexity, operational costs |

| Single-Stage | Low-cost, small operations | Lower cost, simpler design | Less control over the process |

| Multi-Stage | Large-scale, high efficiency | Greater control, higher efficiency | Expensive and complex |

Organic Fraction of Municipal Solid Waste as a Feedstock

Currently, the only biological route for recycling matter and nutrients from the organic fraction of mixed municipal solid waste is through treatment processes such as anaerobic digestion and composting (MSW). The organic content of MSW becomes the feedstock for the Anerobic Digestion process.

Anaerobic digestion has been shown to be a viable option for managing and stabilising the biodegradable fraction of those wastes. It usually results in about a 50% reduction in organic matter (volatile solids).

The degree of conversion varies with the feedstock and is comparable to that obtained by aerobic composting at comparable residence times. The big advantage which AD has over composting is that it produces a renewable energy source – the biogas!

Advantages of the AD Process

It is the organic fraction after sorting and separation of municipal solid waste (MSW) in an MRF or MBT facility which is used as the feedstock for the anaerobic digestion (AD) process.

Municipal solid waste (MSW) contains a large fraction of biodegradable organic materials. When disposed of in landfills, these materials can cause adverse environmental impacts due to gaseous emissions and leachate generation. Taking out the organic materials and applying the AD process drastically reduces the potential for those very damaging impacts.

One economic benefit of using MSW is that the feedstock is almost always provided free of charge after it is collected by waste management companies. In most developed nations the alternative is landfill which can be expensive. The charges for landfill tipping in many countries are driven by landfill taxation. In others, the disposal of organic materials in landfills may even soon be banned.

Therefore, MSW is a rising source for biogas generation.

What Happens in an MSW Digester

There is no big mystery to using the AD process. It is a natural process that breaks feedstock into renewable fuel (here biogas) and digestate by a microbial consortium of organisms in the absence of oxygen.

The main distinction between anaerobic digestion (AD) technologies for the treatment of municipal and industrial biodegradable wastes is the operating process requires optimizing for the solid nature of the feed.

Wet AD systems operate at low total solids (TS) and dry AD systems at much higher TS. For that reason, the dry AD process is often used.

The decision of whether to use a wet or a dry AD system is assessed by considering:

- technical operation (footprint, capacity, feedstock characteristics, pretreatment and post-treatment, retention time, water usage),

- energy balance (biogas productivity, parasitic energy,

- methane [CH4] content,

- utilization of biogas and the produced energy),

- digestate management and

- economic performance (capital and operational costs, revenues, specific capital costs [per t of waste and per m3 biogas]).

When using a Wet AD Process for MSW the organic material is mixed with water to a preset solids content. This increases the volume, all of which becomes digestate, some of which will need to be removed and disposed of daily. A percentage of the water/ digestate cannot be recirculated and this often needs expensive disposal.

That's why many operators like to do no more than thoroughly wet it. They add much less water and manhandle the material with front-end loaders and conveyors. This is the big difference to any wet process where the materials are all pumped.

Dry anaerobic digestion of the organic fraction of municipal solid waste

The traditional Dry AD process is a batch process in which sealed tunnels are filled with organic municipal solid waste. The doors are closed, and the batch is sprayed with previously collected liquid digestate fluid from the previous batches.

Methanogens grow once all the air and oxygen has been consumed by the process. They produce biogas and after a set period of time when the majority of activity has occurred the batch is removed from the tunnel. The digestate (solid and liquid) is usually taken for disposal. The solid material may still be landfilled but the weight has been drastically reduced as has the potential for further biological activity in the landfill.

MSW Plug Flow Digestion Process

A continuous plug flow biogas digestion process in some of the most recent digestion technologies accepts high solids organic feedstock that has been pre-processed to remove physical contaminants. Anaerobic treatment systems, supplied with clean feedstock can then maximise the production of biogas. Not only that! The residuals from the process, are suitable for a wide range of applications as products and requirements for a circular economy are met.

Effectively separating the biodegradable materials from a mechanical biological treatment (MBT) facility and treating them in well-controlled anaerobic digesters for biogas production. Requires specialist equipment and an operator with well-trained staff.

One such technique is to use a dry AD system, based upon a rotary drum reactor (RDR) process.

This should not be confused with the common use of trommel drums for the initial separation of the organic content. separating and preparing the biodegradable materials in MSW to be used as feedstock for anaerobic digestion.

In addition to trommel screening, there are now a number of additional methods used for separating out the organic matter from mixed (“black bag”) household waste.

Mesophilic AD is usually used. Thermophilic anaerobic digestion of municipal solid wastes (MSW) is conducted at only a few locations globally.

Anaerobic Digestion Processes for the Food Waste in MSW

Food waste is a major constituent in municipal solid wastes and its accumulation or disposal of in landfills is problematic, causing environmental issues.

Food waste digestion generates a highly desirable value of methane potential. According to studies, the methane yield from anaerobic digestion ranges between 350 and 435 mL/g VSadded, depending on:

- hydraulic retention time (HRT),

- operational conditions,

- reactor type, and

- input food waste composition.

Biogas production from food waste, along with other renewable organic sources such as agricultural waste, has been proposed as an ideal solution for waste management and energy recovery in the coming decades due to the benefits in terms of energy savings, environmental aspects, and waste management.

The weight of solids produced from wastewater treatment can be reduced through anaerobic digestion, which in turn reduces the costs associated with their disposal.

How Anaerobic Digestion Processes Treat Municipal Solid Waste for Biogas and Waste Diversion

Anaerobic digestion of the organic fraction of waste is an environmentally sustainable waste conversion or processing method that produces methane and digested material that can then be used as a soil amendment.

AD processes can be single-step processes where all the waste is placed into a single digestion stage (biogas reactor tank) or multiple-step processes.

Multiple-step processes usually include a separate hydrolysis stage, which can be either aerobic or anaerobic. Hydrolysis (heating to a high temperature and raising the pressure) is used to optimise the breakdown of complex organic material into soluble compounds. This is most often followed by a high-rate AD process for biogas production.

However, there may be significant advantages in using two stages in the digestion stage as well.

The AD process can take place in a number of vessels, or just one, but normally two are employed, one as a hydrolysis vessel and the second as the digester.

An example would be to use thermal hydrolysis of the organic content of MSW followed by anaerobic digestion to produce biogas that is burnt in an engine electricity generator set. The reason for using a hydrolyser is the addition of this process stage results in more of the degradable material in the feed being converted into biogas, rather than just passing through and emerging in the digestate.

The key process stages which would be seen in the waste processing plant (MBT Plant or MRF) include an MSW reception area, shredding, and a form of wet separator, where the biodegradable material is separated from the inert and reject (sometimes called “contrary”) material.

Anaerobic Digestion of the Organic Fraction of MSW in a Two-Stage Process

Two-stage mesophilic digesters have been shown to provide an improved volatile solids and volatile suspended solids destruction efficiency over a single-stage system (at the same total solids retention time [SRT]).

However, early plants constructed on the basis of two-stage digestion systems apparently failed to meet expectations and the company offering the 2-stage design is no longer trading.

Anaerobic Digestion Processes – Commonly Considered Process Options

Anaerobic digestion of MSW: Energy and carbon emission footprint

Managing the ever-increasing load of municipal solid waste (MSW) with its large organic content is one of the biggest challenges for municipalities all over the world.

Due to its ability to generate methane and a semi-stabilized digestate, which can be further processed as a substitute for inorganic fertilisers, anaerobic digestion (AD) has become a popular technique for MSW management.

According to World Bank reports, global MSW production per year is expected to reach 2. 2 billion tonnes by 2025.

The organic fraction of municipal solid waste (MSW) accounts for more than 40% of the total MSW generated.

Digester Tanks

The digestion process takes place in sealed tanks (digesters) that are normally mixed thoroughly. This is often done by using externally mounted pumps that pull the liquor out into the pump.

While returning it into the digester tank ejects it at speed again into the tank, often also close to the stirring blades, to maximise contact between microbes and waste.

Mixing can also be achieved using the methane gas by pumping it out from the reservoir above the digester reactor into the tank and allowing it to bubble up to the surface to create a mixing effect.

Thermal Hydrolysis

A thermal hydrolysis stage is a feature of many MSW biogas process systems, followed by a one-stage anaerobic digestion process.

The AD plant utilizes the biogas produced is often used to power an engine, which powers a generator, with waste heat recovery that delivers the steam and heat to the hydrolyser and digesters.

It is accepted by many AD professionals that the rate-controlling step in the anaerobic digestion of MSW is the hydrolysis of complex materials such as cellulose, in paper and leaves etc. in the waste.

The process converts the waste into small soluble molecules such as glucose, which can then be easily digested by the biogas producing microbes. In the commercially available process, this conversion is accelerated by heating the material under pressure to around 150°C.

This results in substantially more of the biodegradable material being made available for conversion into gas and ensures the feed material is also sterilized, as required by the EU Animal By-Products Regulations.

After this initial anaerobic composting period (when there is biogas production) the raw compost is placed in windrows (often out in the open) to mature for an additional 5-6 weeks, in the same way as for aerobic composting treatment. The matured compost is then passed through a trommel screen to remove any plastics.

In a final processing step to produce a digestate product for sale, the compost can be blended with additives (e.g. sand, brick dust). Plus, Nitrogen, Phosphorus and Potassium) can be added to meet different specifications from wholesale and retail sellers, and bagged if required.

FAQs

1. What types of waste can anaerobic digestion process?

Anaerobic digestion works best for organic materials such as food waste, green waste, agricultural residues, and sewage sludge. Non-biodegradable materials like plastics and metals must be removed before digestion.

2. How long does the anaerobic digestion process take?

The retention time can vary depending on the type of system and temperature. Psychrophilic systems can take several months, while thermophilic systems can complete the process in 10-20 days.

3. What happens to the biogas produced?

Biogas can be used for generating heat, electricity, or upgraded to biomethane for use as vehicle fuel. It can also be injected into the natural gas grid.

4. Can anaerobic digestion be profitable?

Yes, AD can be economically viable through the sale of biogas, energy generation, digestate as fertilizer, and potential tipping fees for waste disposal. However, profitability depends on factors such as plant size, location, and energy market conditions.

5. Is anaerobic digestion environmentally friendly?

Anaerobic digestion significantly reduces methane emissions from waste and generates renewable energy, making it a more sustainable waste management option compared to landfilling or incineration.

Conclusion – Anaerobic Digestion Processes

The anaerobic digestion process (AD) offers an efficient, sustainable solution for managing the organic fraction of municipal solid waste.

With the right waste stream composition, design, and operational considerations, AD can reduce landfill dependency, produce renewable energy, and create valuable by-products. While not suitable for every waste management scenario, it is a key technology for those focused on circular economy principles and environmental sustainability.

[Article first uploaded in February 2014. Updated July 2021. Latest update September 2024.]

I’m curious to find out what blog platform you have been working with?

I’m experiencing some minor security problems with my latest blog

and I’d like to find something more safeguarded.

Do you have any suggestions?

I am sure this article is well read. How many Council Waste Management Centers use this method? Plus do you know that prospects are bright for alternative usage such as microalgal cultivation, biofuel and bioethanol production.

Where can we get a list of Municipal Solid Waste Centres which are using this technology (Europe)? We would like to contact them.

Municipal solid waste is what we put in the wheelie bin and put out for the bin men. Cut the jargon and tell it in plain language.

I like it whenever people come together and share thoughts. 100% waste diversion for our municipal solid waste is what I favor. Great blog, continue the good work!

I have been doing surveys & research in this field for over 10 years now & find it to be extremely fascinating to use these methods to come to the ‘ Zero Waste ‘ status.

All-in-All, Anaerobic Digestion plus other Renewable Energies would create full independence of a community ……

I do hope my ‘ Green @ Eco Sustainable Society ‘ in a near future would become a good example for this so chaotic spaceship, Earth to combat Global Warming & Climate Change.

DO WISH ME LUCK! from ‘ The City of Angel ‘, Bangkok.

Is this actually lowering emissions of carbon dioxide? It’s probably safe to assume that the trucks are powered by diesel, right?