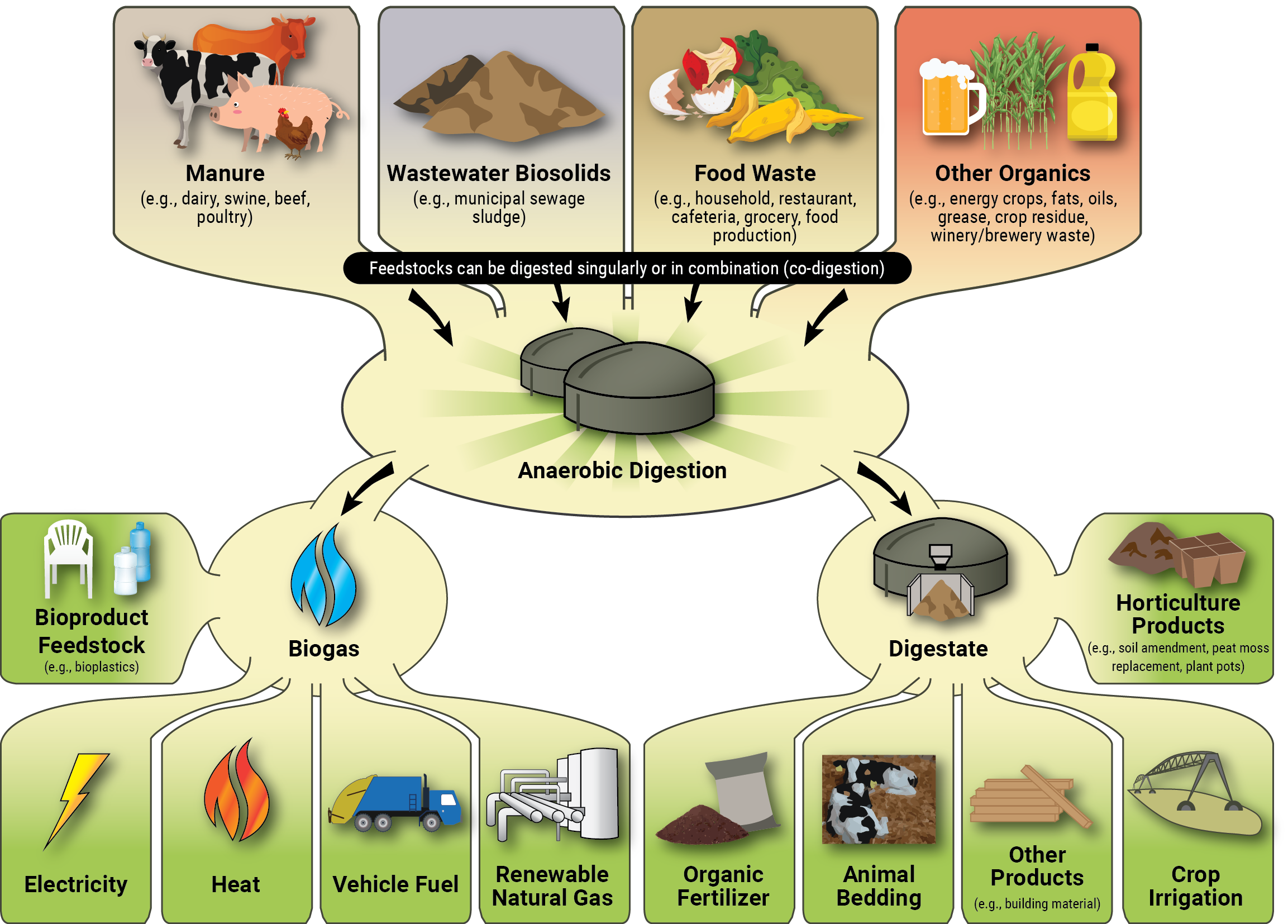

Anaerobic digestion, in which microorganisms break down organic matter without oxygen, can be used to make biogas from food waste. Biogas, a combination of carbon dioxide and methane, is released during this process and can be utilised for heating, cooking, and even producing power. Digestate, the leftover substance, is a fertiliser that is high in nutrients.

Key Takeaways

- Commercial biogas production can reduce greenhouse gas emissions by up to 90% compared to landfill disposal of food waste while generating renewable energy.

- Both commercial and home-scale biogas systems operate on the same anaerobic digestion principles, with feasible options for implementation at any scale.

- The optimal food waste for biogas production contains high levels of fats and carbohydrates, with a proper carbon-to-nitrogen ratio of 20-30:1.

- Commercial biogas facilities can process between 10,000-100,000+ tons of food waste annually, creating revenue through energy generation and tipping fees.

- Home biogas systems can reduce household energy bills while providing nutrient-rich fertiliser as a valuable byproduct.

Turn Your Food Waste Into Clean Energy Today

Food waste represents an untapped energy goldmine sitting in your kitchen scraps and commercial refuse. Every banana peel, coffee ground, and spoiled vegetable can generate clean, renewable energy through biogas production.

With global food waste exceeding 1.3 billion tons annually, we're literally throwing away one of our most accessible renewable energy sources.

Converting this waste into biogas not only addresses waste management challenges but creates a sustainable energy loop that benefits both the environment and your bottom line.

Homebiogas, a leading provider of biogas solutions, offers innovative systems that make this conversion process accessible to both commercial operations and households alike.

What is Biogas and Why Food Waste Makes Perfect Fuel

Biogas is a naturally occurring mixture of gases—primarily methane (50-75%) and carbon dioxide (25-50%)—produced when organic matter breaks down in oxygen-free environments. This renewable energy source can be used just like natural gas for cooking, heating, electricity generation, and even vehicle fuel. Unlike fossil fuels that take millions of years to form, biogas can be produced in weeks, making it one of the most rapidly renewable energy sources available.

Food waste stands out as an ideal feedstock for biogas production due to its high energy content and consistent availability. The carbohydrates, proteins, and fats in food waste break down readily in anaerobic conditions, releasing energy-rich methane in the process. While agricultural residues might yield 50-200 cubic meters of biogas per ton, food waste can generate an impressive 300-600 cubic meters per ton, making it significantly more efficient as a biogas source.

“How Does Anaerobic Digestion Work? | US EPA” from www.epa.gov and used with no modifications.

The Science Behind Anaerobic Digestion

Anaerobic digestion is nature's way of recycling organic matter in oxygen-deprived environments, and it's the cornerstone of biogas production. The process unfolds in four distinct biological stages, each facilitated by specialised microorganisms.

During hydrolysis, complex organic compounds are broken down into simpler molecules like amino acids, sugars, and fatty acids.

Acidogenic bacteria then convert these compounds into volatile fatty acids, alcohols, hydrogen, and carbon dioxide. In the acetogenesis phase, these intermediate products are transformed into acetic acid, hydrogen, and carbon dioxide. Finally, methanogenic microorganisms convert these substances into biogas—primarily methane and carbon dioxide.

Self-sustaining Process

The beauty of this process lies in its self-sustaining nature. Once initiated, the microbial communities maintain themselves as long as fresh organic material is added and optimal conditions are maintained.

Temperature plays a crucial role, with most commercial systems operating in either the mesophilic range (95-105°F or 35-40°C) or the thermophilic range (125-135°F or 52-57°C). The higher temperatures of thermophilic digestion accelerate the process but require more precise control.

- Hydrolysis: Complex organics break down into simple compounds

- Acidogenesis: Simple compounds convert to organic acids

- Acetogenesis: Organic acids transform into acetic acid and hydrogen

- Methanogenesis: Acetic acid and hydrogen convert to methane and CO₂

Environmental Benefits of Converting Food Waste to Biogas

The environmental advantages of biogas production from food waste are both immediate and far-reaching. When food waste decomposes in landfills, it releases methane—a greenhouse gas 25 times more potent than carbon dioxide—directly into the atmosphere.

By capturing this methane through controlled anaerobic digestion, biogas systems can reduce greenhouse gas emissions by up to 90% compared to conventional waste disposal methods. For each ton of food waste diverted to biogas production, approximately 0.5 tons of CO₂ equivalent emissions are avoided.

Beyond emissions reduction, biogas production creates a circular economy around waste. The process yields not only renewable energy but also nutrient-rich digestate that can replace synthetic fertilisers in agricultural applications.

Reduces the Energy-intensive Production of Chemical Fertilisers

This reduces the energy-intensive production of chemical fertilisers while returning valuable nutrients to the soil. Water quality also improves as less leachate from decomposing waste reaches groundwater and waterways.

The combined environmental benefits make biogas production one of the few technologies that simultaneously addresses waste management, renewable energy generation, and agricultural sustainability.

“Food waste-derived biogas represents one of the few renewable energy sources that actually removes more greenhouse gases from the atmosphere than it produces during operation, making it not just carbon-neutral but potentially carbon-negative when displacing fossil fuels.” — International Renewable Energy Agency

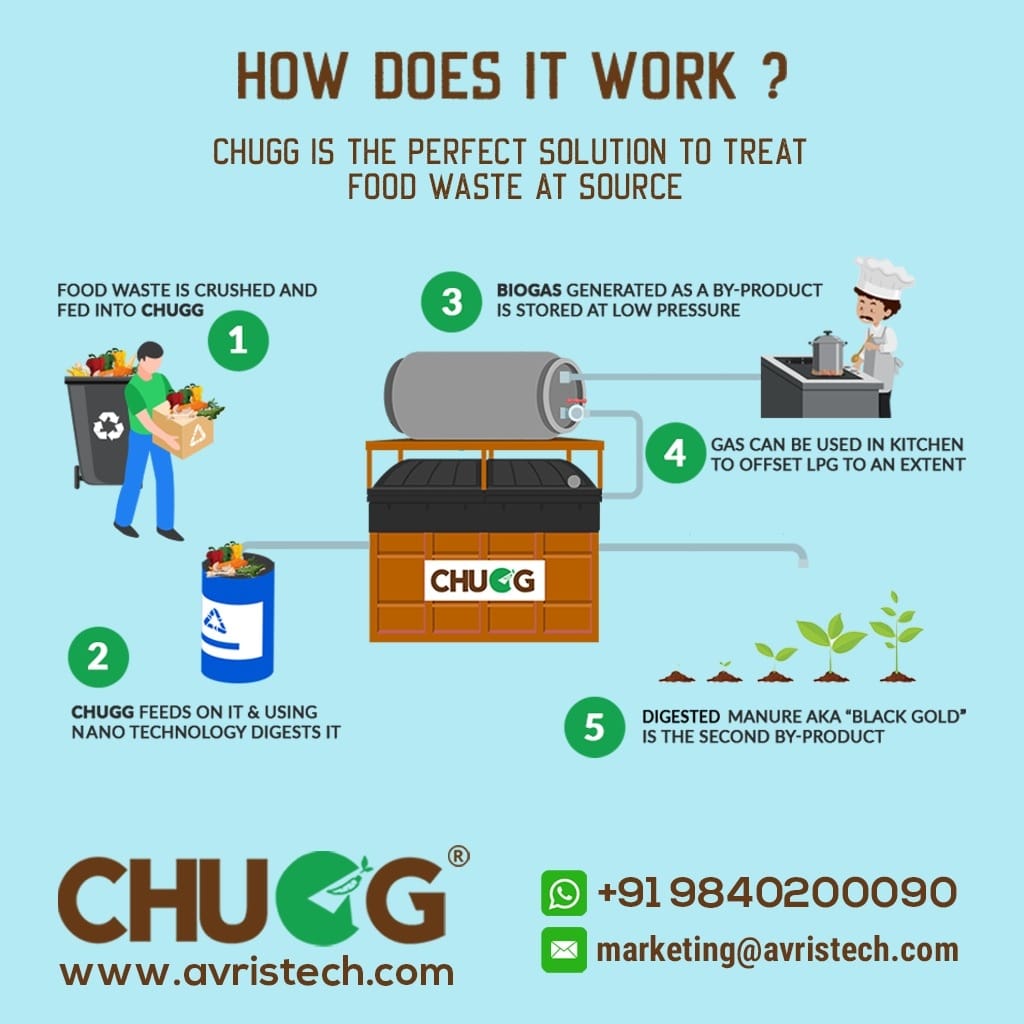

“Biodigesters: A solution for Food waste …” from avristech.com and used with no modifications.

Types of Food Waste That Work Best from Source Separated Council Collections to Food Processing Industry Food Waste, such as Out-of-Date Biscuits, etc

Not all food waste performs equally in biogas production. High-energy food waste containing substantial amounts of fats, oils, proteins, and carbohydrates generates the most methane.

Overripe fruits, vegetables, grains, dairy products, and oils are exceptional biogas producers, with fats yielding up to twice the biogas potential of carbohydrates. Commercial food processing waste—like outdated bakery products, brewery spent grains, and dairy processing residues—offers particularly consistent and energy-rich feedstock.

Source-Separated Collection Systems

Source-separated collection systems, whether municipal or commercial, provide cleaner, more homogeneous food waste streams that require less pre-processing and contamination removal.

Many commercial facilities prefer post-industrial food waste from food manufacturers and processors because it offers predictable composition and arrives in larger volumes.

Restaurant waste, though variable, typically has high energy content due to its fat and oil content. Grocery store waste, particularly from produce, meat, and bakery departments, provides diverse feedstock that can be blended to achieve optimal digestion conditions.

Building a Large-Scale Commercial Biogas System

Commercial biogas facilities operate on a dramatically larger scale than home systems, processing anywhere from 10,000 to 100,000+ tons of food waste annually. These facilities represent significant investments, typically ranging from $5-20 million, depending on capacity and technology sophistication.

However, they generate substantial returns through multiple revenue streams: tipping fees for waste acceptance, biogas energy sales, and digestate marketing. A well-designed commercial plant can achieve payback periods of 5-7 years with proper operations and favourable energy markets.

Essential Equipment for Large-Scale Operations

The heart of any commercial biogas facility is its digester system, but successful operations require comprehensive infrastructure from waste reception to gas utilisation. Receiving areas must include scales for weighing incoming waste, tipping floors for unloading, and sometimes temporary storage bunkers with odour control systems.

Pre-processing equipment typically includes:

- Depackaging machines that don't create microplastics

- Grinding or maceration systems – These are, unfortunately, still used despite creating microplastics.

- Pulpers, hydropulpers are also used for slurry creation, and

- Screening technologies to remove contaminants that, perversely, also create microplastics.

Commercial facilities also require sophisticated mixing systems—whether mechanical agitators, hydraulic recirculation, or gas injection systems—to maintain homogeneity within the digester.

Gas Handling Systems

Gas handling systems represent another critical equipment category, including gas storage (usually in double-membrane gas holders), compression systems, and cleaning technologies. Hydrogen sulfide removal systems, carbon dioxide scrubbers, and moisture removal equipment ensure the biogas meets specifications for its intended use.

If electricity generation is planned, combined heat and power (CHP) units with generating capacities ranging from hundreds of kilowatts to several megawatts will be necessary. Sophisticated automation, monitoring, and control systems tie these components together, allowing operators to maximise production while maintaining safety and compliance. For those interested in reducing greenhouse gas emissions, farm digesters offer a viable solution.

Collection and Pre-Processing Requirements

Successful commercial biogas operations begin with effective waste collection strategies. Collection containers should prevent contamination while minimising odours, often through specialised food waste bins with ventilation features and secure lids.

Collection frequencies must balance transportation costs against decomposition concerns, with most commercial operations preferring 2-3 times weekly collection in warmer months. Upon arrival at the facility, incoming waste undergoes thorough inspection and contamination removal before processing.

Pre-processing

Pre-processing transforms heterogeneous food waste into homogeneous feedstock suitable for digestion. This typically begins with size reduction through hammer mills, shredders, or grinders capable of processing several tons per hour.

Contaminant removal systems then extract non-digestible materials like plastics, metals, and packaging materials. Many facilities employ hydropulping systems that create a pumpable slurry while simultaneously removing contaminants through density separation.

Advanced facilities may incorporate pasteurisation systems (typically heating waste to 70°C for one hour) to eliminate pathogens and comply with regulations, particularly when processing animal byproducts.

Optimal Digester Design for Maximum Output

Digester design fundamentally influences system performance, with several configurations predominating in commercial applications. Continuously stirred tank reactors (CSTRs) remain the most common design for food waste, offering operational flexibility and reliable performance.

These vertically oriented tanks feature mechanical mixers that maintain uniform conditions and prevent stratification. For higher-solid food waste applications, plug-flow digesters create a horizontal flow pattern that moves material through treatment zones with minimal mixing, offering excellent pathogen reduction but requiring more consistent feedstock.

Important Design Parameters

Optimising digester performance requires careful attention to several design parameters. Hydraulic retention time—typically 20-30 days for food waste—must balance complete digestion against reactor volume costs. Organic loading rates (typically 3-4 kg volatile solids per cubic meter per day for food waste) determine the amount of digestible material added daily.

Temperature Control Systems

Temperature control systems, whether external heat exchangers or internal heating coils, maintain optimal biological conditions. Advanced designs often incorporate two-stage digestion with separate hydrolysis/acidification and methanogenesis phases, improving overall efficiency by optimising conditions for different microbial communities.

| Digester Type | Solid Content | Retention Time | Advantages | Limitations |

|---|---|---|---|---|

| CSTR (Continuously Stirred Tank Reactor) | 3-10% TS | 20-30 days | Excellent mixing, operational flexibility | Higher energy for mixing, dilution is required |

| Plug Flow | 11-13% TS | 15-25 days | Less mixing energy, good pathogen reduction | Less suitable for variable feedstocks |

| UASB (Upflow Anaerobic Sludge Blanket) | <3% TS | 1-5 days | Compact design, handles liquid wastes well | Not suitable for solid food waste |

| Two-Stage Systems | 3-15% TS | 15-25 days total | Optimised biology, higher methane yield | More complex operation, higher capital cost |

Biogas Purification and Storage Solutions

Raw biogas contains impurities that must be removed before utilisation, with hydrogen sulfide (H₂S) being particularly problematic due to its corrosive nature. Commercial facilities employ multiple purification methods, from biological oxidation using iron sponge media to advanced chemical scrubbing.

For electricity generation, moisture removal and minimal H₂S reduction may suffice, while biomethane production for grid injection requires more intensive purification to remove CO₂, achieving 95%+ methane content. Pressure swing adsorption, water scrubbing, and membrane separation technologies represent the most common upgrading approaches for commercial applications.

Storage

Storage solutions buffer production fluctuations while ensuring a consistent supply to end-use applications. Most facilities employ low-pressure (0.05-0.5 bar) flexible double-membrane gas holders mounted atop digesters or as separate units, with capacities typically sized to store 6-12 hours of production.

CSTR Gas Holders

These systems feature an outer weather-protection membrane and an inner gas-holding membrane that rises and falls with gas volume. For biomethane grid injection, high-pressure storage (250+ bar) in steel tanks may be required. Sophisticated monitoring systems track gas composition, pressure, and volume while safety systems detect leaks and prevent overpressure conditions.

Monitoring and Control Systems

Advanced instrumentation forms the backbone of efficient commercial biogas operations, providing real-time data on critical parameters and enabling process optimisation. Online gas analysers continuously monitor biogas composition (CH₄, CO₂, H₂S, and O₂), while flow meters track production volumes.

Within the digester, pH probes, temperature sensors, and volatile fatty acid monitoring systems alert operators to biological imbalances before they become problematic. Foam detection systems prevent overflow events, while pressure sensors ensure safe operating conditions throughout the system.

SCADA Integration

Modern facilities integrate these instruments into comprehensive SCADA (Supervisory Control and Data Acquisition) systems that provide centralised monitoring and control. These platforms allow operators to view historical trends, establish optimal operating parameters, and implement automated control strategies.

Smart Machine Learning Algorithms

Advanced systems employ machine learning algorithms that continuously optimise feeding rates and mixing strategies based on performance data. Remote monitoring capabilities enable off-site supervision and emergency alerts, reducing staffing requirements while improving safety. Well-designed control systems can increase biogas yields by 15-20% through process optimisation while significantly reducing operational risks.

Setting Up a Small Home Biogas Digester

Home biogas systems operate on the same biological principles as their commercial counterparts, but at a fraction of the scale and complexity. These systems can process 1-5 kg of food waste daily, generating 1-3 cubic meters of biogas—enough to provide 1-3 hours of cooking gas.

While commercial systems require million-dollar investments, home units can be built for $200-1,000 using locally available materials, or purchased as pre-fabricated units for $500-2,500. The beauty of home systems lies in their simplicity and accessibility, making biogas production feasible for households worldwide.

“Small Scale Biogas Design – Build a …” from www.build-a-biogas-plant.com and used with no modifications.

1. Choose the Right Location

Proper placement maximises both the safety and performance of your home biogas system. Select a location that receives at least 6 hours of direct sunlight daily to maintain optimal digestion temperatures, particularly in cooler climates.

The site should be level and stable, with good drainage to prevent flooding during heavy rains. Maintain minimum safety distances of 10 feet from living spaces and ignition sources to prevent fire hazards and odour issues. The ideal location balances convenience (being close enough to both the kitchen for easy feeding and the point of gas use) with safety considerations. For more detailed insights, explore this guide on digester tankage.

Importance of Access for Maintenance

Access for maintenance represents another crucial factor in site selection. Ensure sufficient clearance around the unit for cleaning, troubleshooting, and eventual emptying of digestate. In colder regions, consider partially burying the digester or incorporating greenhouse covering to maintain temperatures during the winter months.

If using the system year-round in seasonal climates, plan for insulation needs and possibly supplemental heating during colder periods. Remember that biogas production will naturally decrease as temperatures drop below 65°F (18°C).

2. Gather Your Materials

For a basic home biogas system, you'll need surprisingly common materials that can be sourced locally in most areas. The primary container typically consists of a food-grade plastic drum or IBC tank with 200-1000 litre capacity, depending on your household waste volume.

Gas collection requires a flexible membrane or inner tube that expands as biogas accumulates. Plumbing components include PVC pipes (minimum 2-inch diameter to prevent clogging), gas-rated tubing, valves, and connectors—ensure all are rated for gas applications to prevent leaks. A moisture trap, a hydrogen sulfide filter (often using iron filings or iron oxide), and a pressure gauge are essential for safe gas handling.

Importance of Insulation

Beyond these core components, several supplementary materials improve system performance. Insulation materials like foam boards, straw bales, or bubble wrap help maintain optimal temperatures in cooler climates.

A Simple Pressure Indicator and Safety Overpressure Release

A simple water manometer (U-shaped tube with water) serves as both a pressure indicator and a safety release valve. For enhanced functionality, consider adding a gas flow meter, pH testing kits, and thermometers to monitor system health. Remember that quality matters—particularly for gas-carrying components—so invest in proper materials rather than improvising with parts not rated for methane.

3. Build Your Basic Digester

Construction begins with preparing your main digestion chamber. For a barrel-based system, install inlet and outlet pipes at appropriate heights—the inlet approximately two-thirds up from the bottom and the outlet slightly lower to create a natural overflow for digestate removal.

inlet Pipe Orientation

The inlet pipe should extend into the tank and angle downward to deliver food waste below the liquid surface, preventing gas escape during feeding. The outlet should maintain the working liquid level while allowing excess liquid digestate to flow out.

Ensure all connections are watertight using appropriate sealants for plastic materials. For more information on tank construction, you might find this comparison of concrete vs steel biogas tanks helpful.

Slurry Mixture

The slurry mixture inside your digester provides the home for your microbial workforce. Fill the tank 70-80% with water, leaving headspace for gas collection. To kickstart the biological process, add an inoculum containing established anaerobic bacteria—options include cow manure (best source), existing digester material, or commercial inoculum.

Use approximately 20% inoculum to 80% water for initial filling. The first feeding should be modest, gradually increasing as gas production establishes.

Maintain a slightly alkaline pH (7.0-8.0) by adding agricultural lime if needed, as microorganisms perform best in this range.

4. Create the Gas Collection System

The gas collection system safely captures, stores, and delivers biogas to its point of use. Connect a gas outlet pipe to the highest point of your digester, incorporating a water trap to prevent backflow. This pipe feeds into your gas storage—typically an inverted container floating in water (floating drum design) or an expandable bag/balloon.

For floating drum systems, guide rails ensure vertical movement while maintaining a gas-tight seal. For bag systems, ensure the material is UV-resistant and specifically designed for biogas to prevent degradation and leakage. For more information on biogas systems, check out this digester tankage guide.

Gas Pressure Management

Pressure management represents a critical safety aspect of gas collection. Biogas typically operates at low pressure (0.5-3 kPa or 2-12 inches of water column), and exceeding safe limits can damage equipment or create hazards.

Water Column Pressure Relief Valve

A simple water column pressure relief valve provides essential protection—a U-shaped tube with one end connected to the gas line and the other open to the atmosphere, containing water to a depth corresponding to your maximum desired pressure.

This allows excess gas to bubble out if pressure becomes too high, preventing system damage while providing visual pressure indication. For more insights on biogas systems, explore the differences between concrete and steel biogas tanks.

5. Set Up Safe Usage Connections

Connecting your biogas system to cooking appliances requires careful attention to safety and efficiency. Standard natural gas or LPG stoves can be modified for biogas by increasing the jet orifice size by approximately 50%, as biogas has lower energy content.

Dedicated Biogas Stoves

Dedicated biogas stoves eliminate this modification while optimising combustion efficiency. The connection line should include a moisture trap at its lowest point to collect condensation that forms in the gas line. A simple flame arrestor—a fine metal mesh or water bubbler—installed near the point of use provides essential protection against flame flashback.

Avoid Leakage of Biogas!

All connections require appropriate biogas-rated tubing and secure clamping to prevent leaks. Before first use, test all connections with soapy water to detect bubbling that indicates leaks.

Incorporate a main shutoff valve near the digester and another at the point of use, allowing quick gas flow termination in emergencies.

For maximum safety at commercial biogas plants, install a methane detector near gas-using appliances, as biogas is odourless unless artificially odorised. Never use rubber tubing designed for water, as methane will degrade it over time, creating dangerous leak points.

Following the last 5 points will complete your set-up. Now it is time to start using it:

Feeding Your Digester: The Right Food Waste Mix

Proper feeding practices dramatically influence biogas production rates and system stability. Think of your digester as a living ecosystem with specific dietary preferences and limitations. For home systems, daily feeding provides better stability than irregular large batches.

The ideal feeding rate for most home systems is 1-2 litres of food waste per 100 litres of digester volume daily, or 0.7 and 2 kg Volatile Solids (VS) per cubic meter of digester volume per day. Exceed this consistently and you risk “indigestion”—acidification that inhibits methane-producing organisms.

Too little feeding results in reduced gas output, failing to utilise your system's full potential. For more insights on maintaining your digester, check out this guide on digester tankage.

Kitchen Scraps That Produce Most Biogas

Certain food wastes generate significantly more biogas than others due to their composition. Fat-rich waste like cooking oil, meat trimmings, and dairy products can yield twice the biogas of carbohydrate-rich materials, making them premium feedstock when available.

Fruit and vegetable scraps provide an excellent balance with their moderate biogas potential and good digestibility. Starchy foods like rice, pasta, and bread break down readily and produce consistent gas volumes. Coffee grounds, though common in household waste, contribute more to digestate quality than gas production due to their nitrogen content.

Other Kitchen Wastes

Some less obvious kitchen wastes can significantly boost production. Expired dairy products contain both fats and proteins that generate substantial methane. Aquaculture waste (fish cleaning scraps) provides exceptional gas yields but should be introduced gradually to prevent odour issues.

“Even stale beer… can be used”

Even stale beer and wine contribute well, though their liquid nature must be balanced with solid feedstocks. For optimal performance, aim for diversity in your feedstock rather than single-source materials, as varied inputs provide a more complete nutrient profile for your microbial community.

- High performers: Used cooking oil, cheese rinds, expired yoghurt, avocado pits, overripe bananas

- Moderate performers: Fruit peels, vegetable trimmings, stale bread, coffee grounds

- Low performers: Eggshells, citrus peels, onion skins, woody stems

Foods to Avoid

Some food wastes can disrupt digester performance or even harm the microbial community essential for biogas production.

Citrus

Citrus peels contain limonene, a natural antimicrobial that can inhibit methane-producing organisms when present in high concentrations.

Limit orange, lemon, and grapefruit peels to no more than 10% of your total feed.

Common Salt

Excessive salt similarly disrupts microbial activity—avoid adding heavily salted foods like pickles or cured meats in large quantities. Hard woody materials like nut shells, avocado pits, and corn cobs break down extremely slowly, potentially causing physical blockages in smaller systems.

Non-food Items that Should be Meticulously Removed

Non-food items sometimes mistakenly added to digesters can cause significant problems.

- Plastic bags,

- produce stickers,

- twist ties, and

- other packaging

should be meticulously removed before feeding.

Even “compostable” plastics typically require industrial composting conditions and usually won't break down in home digesters.

Beware the Effect of Antibacterial Soaps etc

Antibacterial soaps, cleaning solutions, and medications can kill beneficial bacteria, setting back production for weeks.

Finally, excessive quantities of:

- oils and

- fats can form floating layers that interfere with gas release

while they produce excellent biogas, they should be incorporated gradually and mixed well with other feedstocks.

Balancing Carbon and Nitrogen Ratios

The carbon-to-nitrogen (C:N) ratio fundamentally influences digester performance. Microbial communities require both elements—carbon provides energy while nitrogen builds cellular structures.

The optimal C:N ratio ranges from 20-30:1, balancing these nutritional needs.

Avoiding Ammonia Buildup

Too much nitrogen (low C:N ratio) leads to ammonia buildup that inhibits methane production. Excessive carbon (high C:N ratio) results in slow digestion and reduced gas yields. Most food waste naturally provides C:N ratios between 15-25:1, making it well-suited for digestion, particularly when mixed.

You can actively manage this balance by combining different waste streams. Nitrogen-rich materials include vegetable trimmings, coffee grounds, and legumes, while carbon-rich inputs include bread, rice, pasta, and paper products.

“Browns” and “Greens”

A simple approach for home systems is the “browns and greens” method borrowed from composting—mixing approximately two parts carbon-rich “browns” (bread, pasta, paper) with one part nitrogen-rich “greens” (vegetable scraps, coffee grounds). When digestate develops strong ammonia odours, increase carbon-rich inputs; when digestion seems sluggish, add more nitrogen-rich materials.

“The perfect C:N ratio is like finding the sweet spot on a violin string—when you hit it just right, the whole system resonates with efficiency. For most food waste digesters, maintaining a ratio between 25:1 and 30:1 maximizes methane production while minimizing ammonia inhibition.” — Dr. Anaerobic Digester Designer and Researcher

Proper Preparation Techniques

Preparation significantly impacts how quickly and completely your food waste converts to biogas. Size reduction dramatically increases surface area available to microbes, accelerating breakdown.

Blend, chop, or crush food waste before feeding, aiming for pieces smaller than 2 cm (approximately thumbnail-sized).

This preparation step alone can increase gas production by 15-25% by making materials more biologically accessible. For tough materials like corn cobs or melon rinds, smaller pieces become even more important.

Pre-fermentation

Pre-fermentation offers another powerful preparation technique. Allowing food waste to sit at room temperature for 24-48 hours before feeding initiates the hydrolysis and acidogenesis stages, jumpstarting the anaerobic digestion process.

This works particularly well for fruit scraps, which develop a slightly sour smell as fermentation begins. For systems accepting paper products, pre-soaking in warm water for several hours helps initiate the breakdown of cellulose fibres.

Finally, maintaining consistent moisture content—approximately like a wrung-out sponge—provides optimal conditions for microbial activity. Excessively dry feedstock slows digestion, while overly wet material dilutes the system.

Using Your Biogas: Practical Applications

The versatility of biogas allows it to replace conventional fuels in numerous household applications. Understanding the energy equivalence helps set realistic expectations—one cubic meter of biogas contains approximately 6 kWh of energy, equivalent to 0.6 litres of gasoline, 0.9 kg of wood, or 1.4 kWh of electricity.

A typical home system producing 1-2 cubic meters daily can therefore provide meaningful but partial energy replacement.

Prioritise applications where biogas offers the greatest practical benefit for your situation, typically starting with cooking before expanding to heating, electricity, or other uses.

For more information on how biogas systems can be integrated into home environments, explore our guide on biodigester toilet systems.

Cooking With Biogas

Cooking represents the most efficient direct use of biogas, with modern burners achieving 60% energy efficiency compared to 30-40% for electricity generation.

A standard biogas burner consumes 300-400 litres of gas per hour at full power, meaning a system producing 1,000 litres daily provides 2.5-3 hours of cooking time.

Purpose-built biogas stoves

Purpose-built biogas stoves optimise combustion with properly sized jets and air mixers, but modified LPG stoves work well with enlarged jets (typically 1.5× original diameter) to accommodate biogas's lower energy density. Look for a clear blue flame with minimal yellow tipping, indicating complete combustion.

Cooking Techniques

Cooking techniques can maximise your biogas supply. Simmering uses 40-60% less gas than high-heat cooking, making slow-cooked dishes particularly economical. Pressure cookers reduce cooking time by 50-70% for beans, rice, and tougher meats, significantly stretching your gas supply.

Use Retained Heat Cooking

Retained heat cooking—bringing food to a boil, then transferring to an insulated container to finish cooking—can reduce gas consumption by 80% for appropriate dishes.

Many successful biogas homes use a combination of these techniques, supplementing with conventional fuels only for high-consumption cooking like holiday meals or canning.

For more on how to maximize your biogas efficiency, explore maximizing methane production.

Heating Systems

Space and water heating provide excellent secondary applications for biogas, particularly when cooking needs are already satisfied. Simple biogas room heaters typically use ceramic radiants that glow red when heated by gas flames, providing radiant heat.

These units consume 400-800 litres per hour, depending on size, making them practical for small spaces or occasional use in moderate climates.

Biogas can also fuel modified conventional water heaters with proper burner adjustments, typically requiring 300-500 litres of gas to heat 100 litres of water by 30°C. But only fully qualified and experienced gas engineers should do this.

Hybrid Systems

For larger heating applications, consider hybrid systems that use biogas as a supplement rather than primary fuel. Solar water heating systems with biogas backup provide an excellent renewable energy pairing, with biogas supplying heat during cloudy periods.

Similarly, masonry heaters or rocket mass heaters can use periodic biogas firing to maintain temperatures while primarily running on solid biomass.

The lower flame temperature of biogas (approximately 870°C versus 1,950°C for natural gas) necessitates different heat exchanger designs with larger surface areas for efficient heat transfer.

Electricity Generation from Biogas

Generating electricity from biogas becomes feasible at larger scales, typically systems producing at least 2-3 cubic meters daily. Small internal combustion generators (1-3 kW) can be modified to run on biogas by installing a gas-air mixer between the carburettor and air filter.

These systems typically achieve 20-30% electrical efficiency, meaning one cubic meter of biogas generates 1.2-1.8 kWh of electricity.

The generator's cooling water and exhaust heat can be captured for heating applications, increasing overall system efficiency to 70-80% through a combined heat and power (CHP) configuration.

“Electricity generation makes more sense for periodic backup.”

For most home systems, electricity generation makes more sense for periodic backup than continuous production. Connect your biogas generator to critical circuits rather than the whole-house supply, prioritising refrigeration, communications, and minimal lighting.

Modern systems often incorporate battery storage to accumulate generated electricity for more efficient use. When selecting a generator for modification, four-stroke engines generally perform better than two-stroke designs, with lower maintenance requirements and better tolerance for biogas impurities.

Adequate gas filtering becomes especially important for electricity generation, as hydrogen sulfide can rapidly damage engine components.

Using Digestate as Fertiliser

Digestate—the liquid effluent from your biogas system—represents a valuable byproduct containing nearly all the nutrients from your original food waste in more plant-available forms. This nutrient-rich liquid contains readily available nitrogen, phosphorus, and potassium along with trace minerals and beneficial microorganisms.

Unlike raw food waste, digestate has minimal odour and pathogens are significantly reduced through the anaerobic process. Home systems typically produce 0.8-0.9 litres of digestate for each litre of food waste added, creating substantial fertiliser volumes over time.

Garden Fertiliser Application

For garden applications, dilute fresh digestate at a 1:10 ratio with water before applying to plants to prevent nutrient burn. This solution makes an excellent fertiliser for high-demand crops like corn, tomatoes, and leafy greens.

Digestate particularly excels as a growth promoter during the vegetative phase, with nitrogen predominantly in ammonium form for immediate plant uptake. For longer-term soil building, digestate can be composted with carbon-rich materials like leaves or straw, creating a balanced amendment that improves soil structure while providing nutrients.

Some gardeners use digestate in compost tea brewing, taking advantage of its microbial populations to create powerful liquid fertilisers.

Regular Maintenance Checks

Systematic maintenance prevents many safety issues before they develop into hazards. Establish a monthly inspection routine covering all system components, from the feeding inlet to the point of use.

- Check gas-carrying hoses and tubing for cracking, degradation, or physical damage, replacing any compromised sections immediately.

- Verify that pressure relief valves operate freely and release at designated pressures. Inspect gas filters, particularly hydrogen sulfide scrubbers, ensuring media hasn't been consumed or bypassed.

- Test safety systems regularly to confirm proper operation. Trigger methane detectors using test functions to verify alarms work correctly.

- Check flame arrestors for corrosion or debris accumulation that could restrict gas flow or compromise effectiveness.

- Exercise shutoff valves monthly to prevent seizure from corrosion or sediment buildup.

Annual comprehensive inspection should include dismantling and cleaning critical components like pressure regulators and burner assemblies, which can accumulate deposits over time.

Document all maintenance activities in a logbook, noting replacement dates for consumable components like filter media to establish appropriate service intervals.

Real Success Stories: From Waste to Watts

- HomeGas Initiative (Rwanda): Provided 3,000+ households with small-scale digesters, reducing firewood dependence by 60-80%

- Appropriate Rural Technology Institute (India): Deployed 200,000+ home biogas units, saving 400,000 tons of fuelwood annually

- SNV Domestic Biogas Program (Vietnam): Installed 250,000 biogas digesters, creating 5,000+ jobs in construction and maintenance

- European Biogas Association: Documented 18,000 biogas plants producing energy equivalent to 4% of natural gas consumption

These success stories demonstrate biogas adoption across economic and geographical contexts, from individual households to industrial operations. The technology's scalability allows implementation at virtually any level, with benefits proportional to the operation size.

Common Success Factors

What unites these diverse applications is their conversion of a problematic waste stream into valuable energy and fertilizer, creating environmental and economic benefits simultaneously. Each successful implementation builds technical knowledge and public acceptance, accelerating broader adoption.

Despite differing scales and contexts, successful biogas operations share common characteristics.

Effective systems incorporate locally available materials and skills for construction and maintenance, ensuring sustainability beyond initial installation.

Successful projects emphasize operator training and ongoing support rather than simply providing equipment.

The Value of Community Involvement

Community-based approaches often outperform individual installations by sharing knowledge, creating economies of scale for construction, and providing mutual troubleshooting assistance. Finally, the most successful implementations integrate biogas into broader waste management and agricultural systems rather than treating it as a standalone technology.

Rising Momentum Toward Biogas Systems Development

The growth trajectory of biogas technology shows acceleration as climate concerns intensify and waste management challenges grow. Starting from traditional fixed-dome digesters used for centuries in China, modern systems incorporate advanced monitoring, automatic feeding, and sophisticated gas utilisation technologies while maintaining the same biological principles.

Ancient Knowledge combined with Modern Engineering

This evolution demonstrates how ancient knowledge combined with modern engineering creates increasingly efficient and user-friendly systems accessible to wider populations.

As fossil fuel prices rise and carbon reduction incentives increase, biogas adoption continues to expand from early adopters to mainstream implementation.

Large Scale Dairy Farm Case Study

Meadowbrook Dairy transformed from an environmental liability to a community asset through biogas implementation. This 800-cow operation previously struggled with manure management, facing neighbor complaints about odors and environmental concerns about runoff.

In 2018, they installed a 500,000-gallon plug-flow digester processing both manure and food waste from local food processors. The system now generates 85 kW of continuous electricity (approximately 2,000 kWh daily) while producing heat for farm operations and high-quality liquid fertilizer.

By accepting food waste from local businesses, the farm created a new revenue stream through tipping fees while reducing waste management costs for area food manufacturers.

An Economic Transformation

The economic transformation proved even more significant than the environmental benefits.

The initial system cost of $650,000 was offset by a 30% renewable energy tax credit and USDA Rural Development grant, reducing the actual farm investment to $375,000.

Annual Revenue

Annual revenue from electricity sales ($70,000), tipping fees ($40,000), and reduced fertiliser purchases ($30,000) delivers approximately $140,000 yearly, providing a 2.7-year simple payback on their investment.

Additional Benefits

Additional benefits include virtual elimination of odour complaints, improved community relations, and reduced greenhouse gas emissions equivalent to removing 150 cars from the road.

The farm now conducts monthly tours for schools and community groups, becoming an educational resource while demonstrating sustainable agriculture practices.

Urban Restaurant Transformation

A Restaurant in Portland, Oregon, installed a commercial-scale biogas system processing food prep waste and plate scrapings from their farm-to-table operation.

Their modified shipping container system processes 250 pounds of food waste daily, generating approximately 40 cubic meters of biogas. This energy supplies 70% of their cooking fuel needs while the nutrient-rich digestate fertilises their one-acre urban garden that provides fresh produce for the restaurant.

A Business Advantage

What began as an environmental statement became a compelling business advantage, with the system's $35,000 cost recovered through reduced waste hauling fees and propane purchases within three years.

Beyond financial benefits, the visible biogas system became a powerful marketing tool and educational platform. The restaurant incorporated the “waste-to-energy loop” into their branding, attracting environmentally conscious diners and generating substantial media coverage.

Staff conduct brief biogas demonstrations during slower periods, explaining the circular economy concepts to interested customers.

Other Businesses Inspired to Follow

The restaurant's success has reportedly inspired four other establishments in their region to implement similar systems, creating an informal network sharing operational tips and troubleshooting assistance.

Their implementation demonstrates how biogas can function effectively even in space-constrained urban environments while providing both practical and marketing benefits.

Family Home Energy Independence

The Rodriguez family in suburban Albuquerque, New Mexico, achieved remarkable energy independence through their home biogas system. Their modified IBC tote design processes food scraps from their six-person household plus weekly lawn clippings, generating 1.5-2 cubic meters of biogas daily.

The Rodriguez implementation highlights several success factors relevant to home biogas adoption. They started small with a basic system focused only on cooking, gradually expanding capabilities as they gained experience. Rather than attempting complete energy independence initially, they identified cooking as their highest-value application and optimised their system accordingly.

A Cross-Generational Family Interest

They involved the entire family in system operation, making biogas production a household responsibility rather than a single person's project. Finally, they connected with online biogas communities for troubleshooting assistance and continuous improvement ideas.

Their experience also illustrates how biogas technology builds resilience beyond normal operations. During a three-day power outage following severe storms, the Rodriguez family maintained cooking capabilities, basic lighting, and refrigeration while neighbours relied on emergency services.

Conclusion – Turning Food Waste Into a Sustainable Future

Biogas production from food waste represents one of the most accessible paths to sustainable energy independence.

Unlike many renewable technologies requiring specialized equipment or specific geographical features, biogas works everywhere people generate organic waste—which means virtually everywhere humans live.

The scalability allows meaningful implementation from single households to industrial facilities, while the fundamentally biological process harnesses nature's own recycling system rather than fighting it. By transforming waste from liability to asset, biogas systems create virtuous cycles where environmental benefits align perfectly with economic advantages.

HomeBiogas provides complete biogas solutions that make this transformative technology accessible to everyone, from individual households to large commercial operations, helping you turn your food waste into clean, renewable energy while creating nutrient-rich fertilizer for growing more food.

Frequently Asked Questions (FAQ)

These questions address the most common concerns and information needs for those considering biogas systems. Whether you're planning a home-scale implementation or exploring commercial possibilities, understanding these practical aspects helps set realistic expectations and prepare for successful operation. Remember that biogas technology has been refined over decades of implementation worldwide, creating a substantial knowledge base for new adopters to draw upon.

How much biogas can I expect from my food waste?

Biogas yield varies significantly based on feedstock composition, with typical food waste generating 100-200 cubic meters per ton (or 0.1-0.2 cubic meters per kilogram). In practical terms, a typical family of four generating 2-3 kg of food waste daily can produce 0.3-0.6 cubic meters of biogas—sufficient for 30-60 minutes of cooking. Higher-fat waste like used cooking oil can double this yield, while fibrous vegetable matter produces somewhat less.

Temperature dramatically influences production rates, with systems operating at 35°C (95°F) generating gas approximately twice as quickly as those at 25°C (77°F). For more insights on managing food waste, explore our guide on London’s approach.

For planning purposes, consider these typical biogas yields by feedstock type: fruit and vegetable waste (0.25-0.5 m³/kg), starchy foods like bread and pasta (0.4-0.6 m³/kg), oils and fats (0.7-1.0 m³/kg), and protein-rich foods (0.5-0.7 m³/kg).

Commercial operations typically achieve higher efficiencies through temperature control, optimised feeding regimes, and professional management, with yields approaching the theoretical maximum of 0.8-0.9 cubic meters per kilogram of volatile solids.

Home systems generally operate at 50-70% of these optimal yields due to temperature fluctuations and less precise feeding practices. For more insights on improving biogas production, explore how maximising methane production can enhance efficiency.

Can biogas replace my entire energy needs?

Complete energy independence through biogas alone remains challenging for most households due to the volume of organic waste required. A typical American home consumes 30-40 kWh of electricity and 30-50 kWh equivalent in heating energy daily. Generating this entirely from biogas would require processing 150-200 kg of food waste daily—far beyond what typical households produce. More realistic expectations involve targeting specific high-value energy uses while maintaining conventional supplies for others. Cooking represents the most accessible complete replacement, as a family of four typically needs 0.5-1.0 cubic meters of biogas daily for cooking, achievable from their own food waste.

Partial energy replacement offers more practical benefits while maintaining reliable service. Many successful implementations follow a prioritised approach:

- Primary: Cooking fuel (highest value, most easily replaced, 100% substitution practical)

- Secondary: Water heating (consistent demand, moderate gas volume, 30-50% substitution practical)

- Tertiary: Space heating (seasonal, high volume demands, 10-30% supplementation practical)

- Limited: Electricity generation (lowest efficiency, highest technical complexity, 5-15% supplementation practical)

For those seeking greater energy independence, combining biogas with other renewable technologies creates more comprehensive solutions. Solar photovoltaic systems pair well with biogas, providing daytime electricity while biogas handles cooking and heating needs. Wind generation similarly complements biogas in suitable locations. The digestate byproduct supports growing energy crops like fast-rotation willows or miscanthus that provide solid biomass for heating, creating an integrated energy system. This diversified approach provides greater resilience than relying on any single technology.