Here we explain how to Eliminate CO2 from Biogas, (or CO2 Scrubbing). Biogas can be upgraded to pipeline natural gas quality (biomethane) for use as a renewable natural gas, but as part of the upgrading process, it will be necessary to remove the carbon dioxide (CO2) from the biogas. This upgraded gas may also be used for residential heating and as vehicle fuel. So there are many good reasons for removing the CO2.

[boomdevs_toc]

CO2 will always be found in biogas due to the fact that during anaerobic digestion, (i.e. degradation in the absence of oxygen), organic material is decomposed by bacteria forming a mixture of CO2 and CH4 with trace amounts of H2S and water vapour at saturation pressure.

Common methods used to eliminate CO2 from biogas are:

- water scrubbing (for example by using iron wool – see below.)

- membrane systems

- pressure swing adsorption (PSA) (see -below)

- chemical CO2 absorption

- amine gas treatment

- CO2 by cooling and recovering dry ice.

These systems also generally reduce the H2S and H2O content. Biogas treatment systems, also need to include feed compression on the un-pressurized raw biogas.

Trace components that are often present in biogas are water vapour, hydrogen sulfide, siloxanes, hydrocarbons, ammonia, oxygen, carbon monoxide, and nitrogen.

The most widely used technologies for biogas upgrading are water scrubbing, PSA, membrane and chemical scrubbing. Out of these technologies, water scrubbing and PSA are considered to be most appropriate at a small scale due to their low cost and easy maintenance. via IIT

Water scrubbing is used to remove carbon dioxide but also hydrogen sulphide from biogas since these gases are more soluble in water than methane. The absorption process is purely physical. Usually, the biogas is pressurized and fed to the bottom of a packed column where water is fed on the top… via BioEnergy Consult

In more detail, the typical scrubbing system consists of a Water scrubber with an iron-wool-packed bed connected to a 500-litre water tank, and two tyre tubes which are used in storing the pre-scrubbed (raw) biogas and the scrubbed (purified) biogas. The water scrubber has an inlet for the entry of the raw biogas and a discharge for the exit of the scrubbed biogas. via E-Journal

Biogas upgrading is a vital step to producing high-quality fuel called biomethane with above 90% methane (CH4). Among the various technologies available for biomethane production, water scrubbing is the most extensively implemented technology around the world. via Factors methane

The presence of H2S in biogas can cause corrosion to the equipment, in addition to this, H2S is also dangerous for human and animal health. CO2 contained in Biogas can cause corrosion. Small quantities of H2S contained in biogas are also an impurity that can accumulate and cause corrosion. So the purification process needs to be done in order to qualify biogas as a natural gas substitute which is environmentally friendly and safe for health.

The basic ingredient of biogas purification using water scrubbers is water, which flows in a pressurized or unpressurised biogas purification column from the top to the bottom, of the column in order to absorb CO2 and H2S gases as it does so. The result of purification by using this method was that the levels of H2S in biogas were reduced by 32.8 % while the CO2 content decreased by 21.2 %. via Removal of Carbon Dioxide.

Water wash gas scrubber technology increases the CH4 content of biogas produced with anaerobic digesters. Water wash gas scrubber technology consists of the following main components: Absorption column and desorption column, compressor, blower, cooler and a subsequent dryer unit.

Before biogas meets the water wash gas scrubber, hydrogen sulfur levels should be reduced and most of the water should be taken out. via www.renewable

The Use of an Iron Wool Carbon Dioxide Scrubber

For home-size systems, an easy solution for getting CO2 from biogas is an Iron Wool Carbon Dioxide Scrubber Device, which is one which absorbs carbon dioxide from circulated gas.

A carbon dioxide scrubber is a device which absorbs carbon dioxide (CO2). It is used to treat exhaust gases from an industrial plant. via Wikipedia.

An effective and efficient technology used in purifying raw biogas generated from the prototypic biogas production plant; this technology is otherwise known as Water Scrubbing technology.

Combined Water Scrubbing of Biogas with Iron Wool Packed Bed

The Scrubbing system consists of a water scrubber, with an iron wool packed bed, connected to a 500 litre water tank, as well as two tyre tubes used to store pre-scrubbed (raw) biogas and scrubbed (purified) biogas.

The water scrubber is equipped with an inlet for raw biogas and an outlet for scrubbed biogas. The raw biogas from the plant was collected in a tyre tube and fed directly into the Water scrubber housing the iron wool-packed bed, while the purified biogas from the exit was collected in another tyre tube.

Samples of the gas mixture were taken before and after scrubbing and analyzed with the Pascal Manometric Glass Tube technique.

Results indicated that the methane content of the scrubbed/ purified biogas was raised from 58% to 82% due to the reduction of Carbon dioxide and Hydrogen Sulphide. CO2 was reduced from 31% to 14% while H2S was reduced from 1% to 0.4%.

The corresponding Energy content of the purified biogas was evaluated to be 41MJ/kg which is higher than that of the raw biogas which was evaluated to be 29MJ/kg. via Fundamentals of Renewable Energy

Biogas CO2 from Biogas and Hydrogen Sulphide Scrubbing

Is this how to remove Carbon Dioxide from biogas? Read on!

Put a section of 4″ PVC about a foot long in the line. Fill this with steel wool, the type used for scrubbing pots.

This will rust away similar to the metal above. It is very efficient because of the high amount of surface area presented by the steel wool.

Threaded connections make it easy to replace the wool. The easiest way to determine when to replace the wool is when you can smell the hydrogen sulfide at the burners.

For a farm-sized system, probably the best thing to use is a pair of old 200-litre/44-gallon drums.

Fill the drums with steel turnings or bashed-up rusty tin cans or anything that is iron or steel. The easiest way to do that is to chop out the 3/4″ bung in the top and weld in a 4″ or larger pipe fitting.

The 2″ bung on the other side should have a length of the largest size of steel pipe that you can fit inside a 2″ pipe nipple, and that goes nearly to the bottom of the drum and that is the gas inlet from the gas bag.

The new and larger bung should be the gas outlet from the top of the drum with a 2″ reduction to plastic pipe, with which everything is connected. The wet biogas will flow slowly through the drum and the metallic iron and the rust will react with the Hydrogen sulfide.

You should have two of these drums made up and rotate them at suitable intervals to make sure that no H2S gas is getting through the system, or your intermediate gas compressor for Biogas CO2 Scrubbing will not last for very long. via Appropedia

Pressure Swing Adsorption (PSA) Systems for CO2 and Hydrogen Sulphide Scrubbing

Pressure swing adsorption (PSA) systems, can be thought of as being molecular sieves for carbon. PSA has been described are the second most commonly used biogas upgrading technology in Europe, after water scrubbing which is most likely the most popular. A typical system is composed of four vessels in series that are filled with adsorbent media which is capable of removing not only the CO2 but also water vapour, N2, and O2 from the biogas flow.

Typically in order to eliminate CO2 from biogas, the PSA upgrading takes place over 4 phases: pressure build-up, adsorption, depressurization and regeneration. The pressure build-up occurs by equilibrating pressure with a vessel at the depressurization stage. Final pressure build-up occurs by injecting raw biogas. During adsorption, CO2, N2, and O2 are adsorbed by the media and the purified gas discharges as pure methane to a quality which will be far less corrosive and has a higher calorific value.

Recently developed gas-liquid membranes have been introduced, which operate at atmospheric pressures thereby reducing the energy consumption of compression. The use of specific solvent solutions allows the separation and recovery of the H2S and CO2.

Dry Ice

Another approach to improving the economics of gas upgrading has been to recover the CO2 by cooling and recovering dry ice. This can then be sold as an industrial gas whilst the biogas is either used in its more concentrated form (80-90% CH4) or further refined to vehicle quality standard (>96% CH4).

Membrane Separation

An example of the use of a membrane for the elimination of CO2 from Biogas follows:

“Silicone (PDMS) has a very high permeability to CO2 compared to methane. This difference in permeability facilitates the transfer of CO2 preferentially over methane, thus enabling the removal of CO2 from a natural gas stream. Similarly other contaminants such as hydrogen sulfide (H2S) and water (H2O) can be readily removed from methane. The separation factor for CO2/CH4 is approximately 3 for a 50/50 gas mix, indicating that the ratio of the mass fraction of CO2 to CH4 in the feed/retentate is three times smaller than the ratio in the permeate.

Natural Gas purification is simple and straightforward as shown in the figure below. The feed gas is supplied to one side of the membrane though the feed port, and depending on the feed pressure, a vacuum supply to the opposite side of the membrane may be necessary at the permeate ports. The contaminants with higher permeability than natural gas will permeate the membrane much faster than the methane, thereby stripping the feed from these contaminants. The high purity natural gas will exit at the permeate port. The permeate can be vented or flared as necessary.”

Mongabay News, Pre-Combustion CO2 Capture [Link no longer available.]

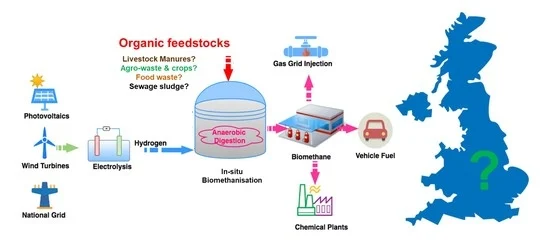

2022 Update: Think Laterally and Consider Biomethanisation by Hydrogenation

Instead of removing CO2, in which the sale of the CO2 may be of limited value. Why not convert it to additional methane?

The sale of CO2 from raw biogas can be difficult. This occurs due to concerns about its use as a waste-based product with the potential for the presence of impurities which make it unpalatable for its use in food production.

Converting the carbon dioxide within a digester into methane by injecting hydrogen was a new idea at the 2022 Biogas Expo, and the word is that it is being done successfully in trials at several digester locations in the UK.

A paper published in June 2022 on the “Potential for Biomethanisation of CO2 from Anaerobic Digestion of Organic Wastes in the United Kingdom [Ref: 1], concludes as follows:

“Based on the available UK data, … significant increases in biomethane productivity could potentially be achieved, ranging from 38–68% for different feedstock types and equivalent to an overall uplift in the contribution of AD to UK bioenergy from 15 to 22%.

Again, there are many issues to consider: the current survey only looked at data on the highest level, and for realistic assessments of the potential scale and impact of technology application it will be necessary to take into account both the end-uses of biomethane and techno-economic viability on individual sites. The potential contribution from CO2 biomethanisation of organic wastes is large enough, however, to warrant consideration in both short and long-term planning.”

The following flow chart shows the hydrogen injection concept:

It appears that equipment, such as the GasMix Digester Tank Mixer systems supplied by Landia which normally re-inject biogas to aid mixing, is being modified to inject pure hydrogen generated on-site from solar cells.

Rumour has it that a remarkably higher biomethane output can be achieved possibly as high as quoted in the above paper “ranging from 38–68%”!

At the same time, the CO2 concentration is drastically reduced, and the resulting quality of the biogas is rumoured to be close to gas grid injection quality.

Why Is It “Green” to Eliminate CO2 from Biogas?

The purification of biogas for higher-value applications, such as vehicle use or pipeline quality, is established to be in general a more sustainable and environmentally friendly option than conversion of the energy to electricity as the energy losses from power generation and the transmission losses for electricity are in general higher than for direct uses of the gas as fuel.

Also, the AD Process is uniquely able to produce transport fuels, whereas other renewable energy sources such as wind turbines, and hydro-power don't, which suggests that it is best utilized to meet the demand for transport fuels.

The energy efficiency for transport fuel use of upgraded biogas (biomethane) is particularly good where the upgraded gas is used to fuel vehicles working in the same facility, or operating from the location.

In more and more nations the natural gas grid is operated independently from the gas producers. If so, and a market exists whereby the gas can be bought nominally from any supplier's source, it becomes highly efficient for buyers to purchase biomethane, even from a very remote digester.

The biomethane (natural gas substitute – Renewable Natural Gas (RNG)) is injected at the remote location and an equivalent amount is drawn off from any other location on the gas grid. The buyer purchases RNG but actually draws it locally from the gas main.

The technology for biogas upgrading really only started to gain traction in 2017. So it is relatively new and improvements to the upgrading processes are ongoing to reduce methane losses and improve energy efficiency.

We hope you found this article on how to eliminate CO2 from biogas useful, we also have another article here, about “Biogas Upgrading Technologies and the Cost of Biomethane Production”.

Frequently Asked Questions

What is the purpose of removing CO2 from biogas?

Removing CO2 from biogas upgrades it to pipeline natural gas quality (biomethane), making it suitable for use as a renewable natural gas. The fully upgraded gas with quality control applied can be sold as high-value biomethane for residential heating and as vehicle fuel, making the removal of CO2 an essential part of the profitable operation of the anaerobic digestion process.

However, for many small-to-medium-scale biogas plant operators using basic wire-wool scrubbing with no quality control applied can be very worthwhile to improve the biogas quality and reduce its corrosivity.

What are the common methods of eliminating CO2 from biogas?

Common methods include water scrubbing, membrane systems, pressure swing adsorption (PSA), chemical CO2 absorption, amine gas treatment, and CO2 removal by cooling and recovering dry ice. These systems generally also reduce the H2S and H2O content.

What does a water scrubbing system consist of?

The typical scrubbing system consists of a water scrubber with an iron-wool-packed bed connected to a 500-litre water tank, and two tyre tubes which are used to store the pre-scrubbed (raw) biogas and the scrubbed (purified) biogas.

What is the effect of water scrubbing on the methane content of biogas?

Water scrubbing raises the methane content of the purified biogas due to the reduction of Carbon dioxide and Hydrogen Sulphide. For example, methane content can be raised from 58% to 82%.

What is the use of an Iron Wool Carbon Dioxide Scrubber?

An Iron Wool Carbon Dioxide Scrubber is a device which absorbs carbon dioxide from circulated gas. It is used to treat exhaust gases from an industrial plant and can be particularly effective in purifying raw biogas.

How does Pressure Swing Adsorption (PSA) work?

PSA works like a molecular sieve for carbon. It removes not only CO2 but also water vapour, N2, and O2 from the biogas flow. It involves four phases: pressure build-up, adsorption, depressurization and regeneration.

Can CO2 from biogas be converted into additional methane instead of being removed?

Yes, instead of removing CO2 from biogas, which may have limited value, it can be converted to additional methane. This is done by injecting hydrogen into a digester, converting the carbon dioxide within it into methane.

Why is it beneficial to eliminate CO2 from biogas?

Eliminating CO2 from biogas allows it to be purified for higher-value applications, such as vehicle use or pipeline quality, making the process more sustainable. Additionally, it reduces the environmental impact of biogas usage.

Reference:

- Bywater, A.; Heaven, S.; Zhang, Y.; Banks, C.J. Potential for Biomethanisation of CO2 from Anaerobic Digestion of Organic Wastes in the United Kingdom. Processes 2022, 10, 1202. https://doi.org/10.3390/pr10061202

[Originally published: September 20018. Article Updated: July 2022. FAQs Added August 2023.]

So cool to learn from this site. I now understand more about CO2 removal but will be glad if I can know how to seperate the whole unwanted gas.

how to remove carbon dioxide, hydrogen sulfide from bio gas

i AM INTERESTED TO KNOW THE REMOVAL OF UNWANTED GAS FRO BIO GAS

Thank you for this great knowledge, it is impressive but yet I you dint put up some equations to validate your statements. over all it is good

Natural Gas upgrading is simple and straightforward as shown in the figure below. A pressurized feed gas is supplied to one side of the membrane though the feed port, and depending on the feed pressure, a vacuum supply to the opposite side of the membrane may be necessary at the permeate ports. The contaminants with higher permeability compared to natural gas will permeate the membrane much faster than the methane, thereby stripping the feed from these contaminants. A higher purity natural gas will exit at the permeate port. The permeate can be vented or flared as necessary. we explain it all at http://permselect.com

We are familiar with the user of dry-ice for the stage performances. This is the same? Yes? Gracias tenga un buen día

Murray Wynn New Zealand

Very interested in what you have to offer.

Hi, I have built a home Biogas digester system and its producing gas, however, it is not burnable gas. I have tested the produced gas and I’m detecting O2 level =20, co2 level= 20, and h2s level=0. ( I have observed whenever I poured fresh warm water in the system the gas reading numbers decreased from high to low, example, oxygen level would be dropped down from 20 to 1.2 and as the pouring slowed down the oxygen level started to come back up).

My quest is can anyone tell me how do I eliminate all the above gases I mentioned and to have just pure burnable Methane? Please send an email to sophett@gmail.com or I’ll keep checking back on this site.

Thank you.

How long has your digester been set-up for? Has it been inoculated with dung, or something similar to be sure you have introduced anaerobic organisms? My guess is that you need to be patient, but if you have air in the system you certainly need to minimize it, the gas collector needs to start off deflated or depending on the design, filled with water/ substrate. If you are adding fresh warm water you are introducing dissolved oxygen, which is being consumed by the oxygen-loving bacteria to produce the CO2 you see. I don’t know why the oxygen would rise again though. Why add water? You will just delay the production of methane, surely? Check whether air is getting into the system somewhere. Only after the oxygen process acetogenesis has consumed the air present at the start, will the methanogens start to grow. That can take some time to take place, depending on the reactor temperature and many other factors.

And i’m glad reading your article. But want to remark on few general things.

AirScience Technologies offers several processes to separate and remove carbon dioxide (CO2) from biogas and natural gas.

Vacuum Pressure Swing Adsorption (VPSA) Process

Vacuum Swing Adsorption (VSA) Process

Amine Scrubbing Process.

Take a look at their website:

https://www.airscience.ca/purification-by-co2-removal

Your website style is great, the articles is really great : D.

I like your website. Useful page.

Your blog is very informative. Here you explain that how to eliminate the CO2 from biogas. This information is very useful.

Thanks for sharing thios information.

It was the exact information that I was looking for relating to eliminating CO2 from Biogas. Thank you for sharing such useful information. Now I understood the whole concept.

I’m extremely interested in finding out how much these tech devices will cost.