As the world shifts towards sustainable energy solutions, renewable natural gas (RNG) stands out as a pivotal player in transforming the transportation sector. At the heart of RNG is biogas, a versatile and eco-friendly fuel that is revolutionizing vehicle fleets worldwide. This article delves into how biogas is making transport renewable, the benefits of biomethane, and the substantial carbon reduction it offers for transportation fleets.

This fuel (known as RNG or rCNG (Renewable Compressed Natural Gas), rLNG (Renewable Liquified Natural Gas), when compressed in cylinders) is as sustainable as it is possible to get today in 2025, and is truly “green” when distributed for use as fuel for natural gas transport use.

Understanding Renewable Natural Gas (RNG)

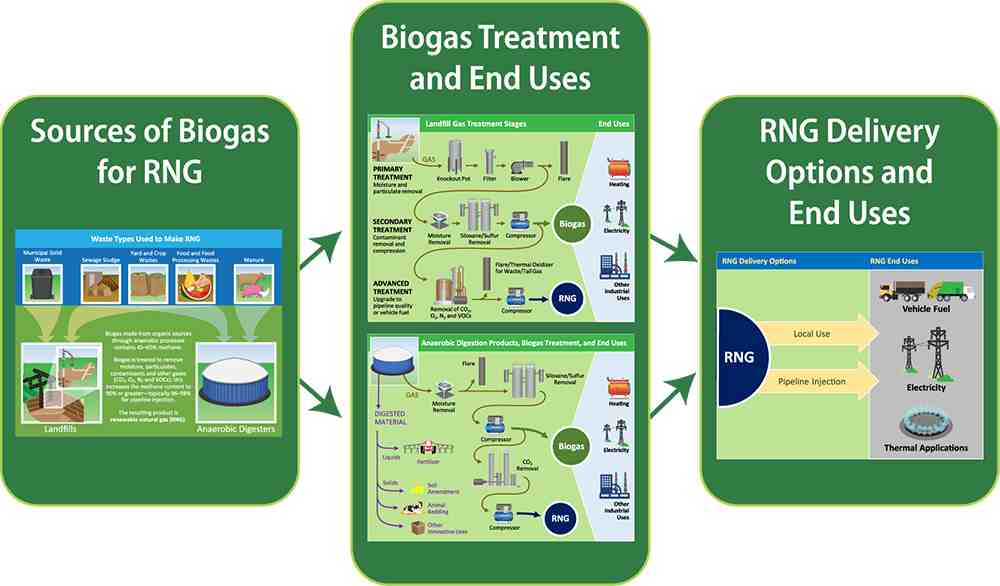

Renewable Natural Gas, often referred to as biomethane, is a clean-burning gas derived from organic waste materials. Unlike traditional fossil fuels, RNG is produced through the decomposition of organic matter, such as agricultural residues, manure, municipal solid waste, and wastewater. This sustainable process not only generates energy but also mitigates greenhouse gas emissions, making RNG a cornerstone in the fight against climate change.

There are many benefits in the use of renewable natural gas transport using biomethane from the anaerobic digestion process.

Rather than deliberately extracting unsustainable fossil-fuel natural gas trapped in the ground, this green gas makes use of resources already present in our surroundings. RNG is produced from current resources using advanced biogas clean-up technology, resulting in a green gas that can be pumped into existing natural gas pipes.

But, before we discuss those, let's define what we mean by renewable natural gas:

What is Renewable Natural Gas?

Renewable natural gas (RNG) is a pipeline-quality gas that may be used in natural gas cars since it is entirely interchangeable with conventional natural gas.

RNG is simply biogas (methane – the gaseous byproduct of organic matter breakdown) that has been purified. RNG, like conventional natural gas, may be utilised as a transportation fuel in the same way as compressed natural gas (CNG) or liquefied natural gas (LNG) (LNG). The “Renewable Fuel Standard” classifies RNG as an advanced biofuel.

Another name for this refined pipeline-quality fuel is biomethane, which refers to biogas that has also been cleaned and conditioned to eliminate or decrease non-methane components. Instead of being used in automotive applications, this processed biogas is used as a replacement for regular natural gas to create combined electricity and heating for power plants.

What is Biogas Conditioning or “Upgrading”?

Conditioning or upgrading refers to the removal of water, carbon dioxide, hydrogen sulphide, and other trace components. The resultant renewable natural gas RNG, or biomethane, contains more methane than raw biogas, making it similar to ordinary natural gas and therefore a useful energy source in all uses requiring pipeline-quality gas.

The Production of Biogas

Biogas production involves several stages, each crucial to ensuring the quality and purity of the final product. The process begins with the collection of organic waste, which is then subjected to anaerobic digestion—a biological process that breaks down the material in the absence of oxygen. This results in the generation of biogas, primarily composed of methane (CH₄) and carbon dioxide (CO₂).

Key Steps from Biogas Production to Vehicle Fuel:

- Feedstock Collection: Gathering organic waste from various sources.

- Anaerobic Digestion: Breaking down the waste in a controlled environment.

- Biogas Purification: Removing impurities to produce high-quality biomethane.

- Compression and Distribution: Preparing the biomethane for use as vehicle fuel.

Benefits of Using Biogas for Vehicle Fuel

Environmental Advantages

Biogas as a vehicle fuel offers significant environmental benefits, making it an attractive alternative to conventional fossil fuels.

- Carbon Neutrality: The carbon dioxide emitted during the combustion of biomethane is offset by the carbon dioxide absorbed during the growth of the organic feedstock, resulting in a balanced carbon footprint.

- Reduced Greenhouse Gas Emissions: Utilizing biogas prevents methane, a potent greenhouse gas, from being released into the atmosphere.

- Air Quality Improvement: Biomethane burns cleaner than diesel or gasoline, leading to lower emissions of pollutants such as nitrogen oxides (NOx) and particulate matter (PM).

Economic Advantages

Adopting biogas as a vehicle fuel can offer economic benefits for fleets and businesses.

- Cost Savings: In many regions, RNG can be more cost-effective than traditional fossil fuels, especially when considering long-term price stability.

- Energy Security: By relying on locally produced biogas, regions can reduce their dependence on imported fuels, enhancing energy security.

- Incentives and Rebates: Governments often provide financial incentives for the adoption of renewable fuels, helping to offset initial setup costs.

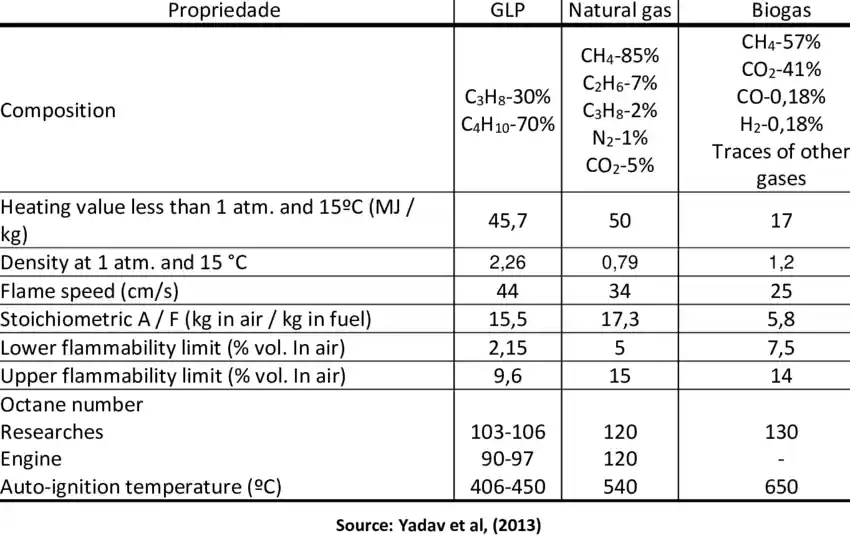

Table: Comparative analysis of LPG (Read “GLP”) Natural Gas and Raw Biogas

“LPG, natural gas and biogas …” from www.researchgate.net and used with no modifications.

Note: Renewable Natural Gas closely resembles natural gas as shown above.

Implementing Biogas in Transportation Fleets

Transitioning to biogas-powered vehicles involves careful planning and collaboration. Here’s how fleets can integrate RNG into their operations seamlessly:

- Fleet Assessment: Evaluate the current fleet’s fuel consumption and identify suitable vehicles for conversion or replacement with biogas-compatible models.

- Infrastructure Development: Establish refueling stations equipped to handle biomethane. This may involve retrofitting existing facilities or building new ones.

- Vehicle Conversion: Convert existing vehicles to run on biogas or invest in new, purpose-built biomethane vehicles.

- Supplier Partnerships: Partner with reliable biogas suppliers to ensure a steady and high-quality fuel supply.

- Training and Support: Provide training for drivers and maintenance staff to handle biogas vehicles efficiently.

“New refuelling station helps CNG fleet …” from www.fleetpoint.org and used with no modifications.

A fleet vehicle being refueled with biomethane at a refueling station

Case Studies: Success Stories in Biogas Adoption

Several forward-thinking companies have successfully integrated biogas into their transportation fleets, reaping both environmental and economic benefits.

Example 1: GreenTransit Logistics

GreenTransit Logistics revamped its fleet by transitioning to biogas-powered trucks. This shift resulted in a 30% reduction in greenhouse gas emissions and significant fuel cost savings. The company also highlighted improved public perception and compliance with increasingly stringent environmental regulations.

Example 2: EcoCity Buses

A metropolitan transit authority introduced biogas-powered buses into its public transportation system. The initiative not only enhanced air quality in the city but also secured grants and incentives that supported the project's financial viability. Ridership increased as the public recognized the commitment to sustainability.

Image: Biogas-powered buses in operation within an urban setting

Carbon Reduction Benefits for Transportation Fleets

Adopting biogas as a vehicle fuel is a powerful strategy for reducing carbon emissions. Here’s how it contributes to a greener future:

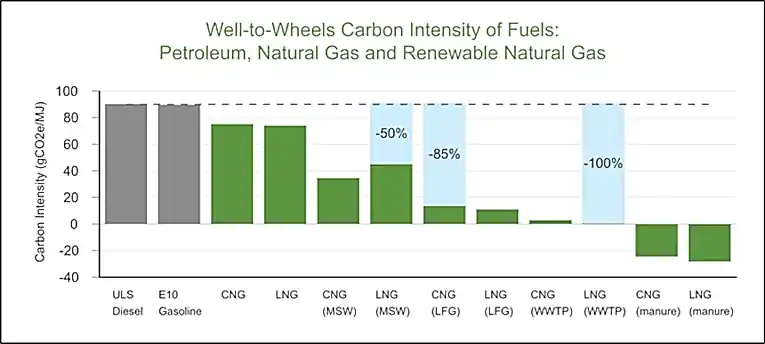

- Lifecycle Emissions Reduction: From production to combustion, biogas pathways typically result in lower lifecycle emissions compared to fossil fuels.

- Methane Mitigation: Capturing methane from waste sources for energy use prevents its potent greenhouse effects in the atmosphere.

- Sustainable Resource Use: Biogas production supports circular economy principles by turning waste into valuable energy, promoting resource efficiency.

Carbon emission reductions achieved by fleets using biogas

“Well to Wheels Carbon Intensity of Fuels” from www.sec.gov and used with no modifications.

Supporting a Sustainable Future

Transitioning to renewable natural gas is more than just a business decision; it’s a commitment to sustainability and environmental stewardship. By choosing biogas, transportation fleets can lead the way in combating climate change, enhancing air quality, and promoting a resilient energy system.

Oil Giants Support Renewable Natural Gas Transport

According to a March 18, 2021 announcement, BP is partnering with Aria Energy in a project to convert methane from California dairy farm waste into renewable natural gas.

This will increase its participation in the RNG transportation fuel industry as it strives to become a net-zero corporation by 2050 at the latest.

According to the announcement, BP will provide “the RNG to the transportation sector under a 20-year offtake deal negotiated by its low carbon trading company.”

According to a US Department of Energy research, RNG-powered cars emit up to 95% less pollution than gasoline or diesel-powered vehicles during their lifetime.

Because of its reduced carbon intensity, RNG is an appealing fuel for corporations with large fleets of cars looking to reduce their carbon impact.

The Path Forward: Embracing Biogas for a Greener Tomorrow

The transportation sector is a significant contributor to global greenhouse gas emissions, but it also offers immense potential for positive change. By embracing renewable natural gas, fleets can make substantial strides towards sustainability while enjoying economic and operational benefits.

Key Steps to Get Started:

- Evaluate Your Fleet’s Potential: Assess how biogas can fit into your current and future operations.

- Engage with Experts: Partner with specialists who can guide you through the transition process.

- Secure Funding and Incentives: Take advantage of available financial support to minimize upfront costs.

- Implement and Optimize: Roll out biogas solutions in phases, ensuring smooth integration and continuous improvement.

Frequently Asked Questions

1. What is the difference between biogas and biomethane? Biogas is the raw gaseous product from anaerobic digestion, primarily composed of methane and carbon dioxide. Biomethane is the purified form of biogas, with most impurities removed, making it suitable for use as a vehicle fuel.

2. How does biomethane compare to traditional natural gas?Biomethane and traditional natural gas are chemically similar, allowing biomethane to be utilized in existing natural gas infrastructure. However, biomethane has a lower carbon footprint and is sourced from renewable materials.

3. What types of vehicles can run on biomethane? A wide range of vehicles can operate on biomethane, including passenger cars, buses, trucks, and even trains. Specialized engines or conversion kits may be needed to ensure compatibility.

4. Are there any government incentives for adopting biogas? Many governments offer incentives such as grants, tax credits, and rebates to encourage the adoption of renewable fuels like biomethane. These can significantly offset the costs of transitioning to biogas.

5. How reliable is the supply of biomethane? With increasing investments in biogas production facilities and infrastructure, the supply of biomethane is becoming more reliable and widespread, ensuring that fleets can depend on a steady fuel source.

Join the Renewable Revolution

Adopting renewable natural gas is a forward-thinking decision that benefits not only your fleet but also the planet. By leveraging biogas, you can achieve significant carbon reductions, enhance operational efficiency, and position your organization as a leader in sustainability.

Take the first step towards a greener future. Contact us today to explore how biogas can transform your transportation fleet.

of human-related methane emissions in the United States (EPA).

Because the digestion process takes occur in the earth rather than an anaerobic digester, biogas from landfills is also known as landfill gas (LFG).

According to the EPA, there were around 564 operating LFG projects in the United States as of June 2020. However, the majority of those use biogas to generate electricity rather than renewable natural gas vehicles.

[Original article posted May 2016. Updated September 2021. Rewritten May 2025.]

Hi! This is not new in Sweden. You guys should go over there. They’ve been using biogas to power their buses for possibly more than 10 years, possibly even trains as well.

Could they also catch the CO2 that is produced throughout the process and store it in a container or pump it into Biochar, which they might then spread on the ground where plants could benefit from it?