Anaerobic digestion biomethane “gas to grid” (Biomethane Gas-Main Injection in England) has since 2017 become a lot more popular (for new biogas plant installations) than the previous favourite of “electricity to grid” installations.

We predict that the trend of new biogas plants to move away from being “biogas electricity generators” to “biogas upgraders” (producing high purity biomethane) will continue and that gas to grid AD plants will soon also be operating in Scotland and Northern Ireland.

The Renewable Energy Transition

The transition to renewable energy sources is imperative for reducing carbon emissions and combating climate change. Severn Trent's Minworth Biogas project exemplifies this shift by harnessing anaerobic digestion to produce biomethane, a renewable substitute for natural gas.

By successfully injecting biomethane into the UK’s natural gas grid, Minworth Biogas not only showcases technological innovation but also underscores the viability of biomethane as a cornerstone of the UK's energy strategy.

It's easy to forget that gas grid connections were pioneered as recently as 2015 in the UK as they seem to be commonplace now. The earliest agricultural biogas plant, that we are aware of, to start injecting their biomethane into the natural gas grid was that operated by Wyke Farms.

Anaerobic Digestion Gas to Grid – Biomethane Gas-Main Injection in England

Severn Trent's Minworth Biogas facility marks a significant milestone in the UK's renewable energy landscape as the first project to inject renewable biomethane directly into the national gas grid. This groundbreaking initiative leverages anaerobic digestion technology to convert organic waste into clean energy, setting a precedent for sustainable energy solutions across the nation.

What is Anaerobic Digestion?

Anaerobic digestion (AD) is a biological process through which microorganisms break down organic material in the absence of oxygen. This process occurs in specially designed digesters and results in the production of biogas, a mixture predominantly composed of methane and carbon dioxide.

Key Stages of Anaerobic Digestion:

- Hydrolysis: Complex organic molecules are broken down into simpler soluble compounds.

- Acidogenesis: These compounds are further decomposed into volatile fatty acids.

- Acetogenesis: Acetic acid is produced, which is a precursor for methane generation.

- Methanogenesis: Methane-producing bacteria convert the acids into methane and carbon dioxide.

“The history and technology of biogas …” from www.skylineenergy.ca and used with no modifications.

Biomethane and Its Importance

Biomethane, also known as renewable natural gas (RNG), is a high-quality energy source derived from biogas through purification processes that remove impurities and excess carbon dioxide. Biomethane is chemically identical to fossil-based natural gas, making it a versatile and sustainable alternative.

Benefits of Biomethane:

- Carbon Neutral: Biomethane production and usage emit no net greenhouse gases.

- Energy Security: Diversifies the energy supply and reduces dependence on fossil fuels.

- Waste Management: Converts organic waste into valuable energy, addressing waste disposal challenges.

Insert Table: Comparison of Biomethane and Natural Gas

Severn Trent's Minworth Biogas Facility

Located in Minworth, the Severn Trent Biogas facility stands as a pioneering project in the UK's renewable energy sector. As the first plant to inject biomethane into the national gas grid, Minworth Biogas sets a benchmark for future anaerobic digestion projects.

Key Features of Minworth Biogas:

- Capacity: Capable of processing significant quantities of organic waste to produce substantial amounts of biomethane.

- Technology: Utilizes advanced AD technology to maximize biogas yield and efficiency.

- Sustainability: Designed with minimal environmental impact, incorporating energy-efficient systems and sustainable practices.

Process of Biomethane Production at Minworth

The production of biomethane at the Minworth facility involves several meticulous steps to ensure the quality and purity of the gas injected into the grid.

- Feedstock Collection: Organic waste, including agricultural residues, food waste, and sewage sludge, is collected and transported to the facility.

- Pre-treatment: The collected waste undergoes screening and sorting to remove non-organic materials.

- Anaerobic Digestion: The pre-treated waste enters anaerobic digesters where microorganisms facilitate the breakdown of organic matter, producing biogas.

- Biogas Upgrading: The raw biogas is purified to remove impurities, resulting in high-purity biomethane suitable for grid injection.

- Injection into the Gas Grid: The purified biomethane is securely injected into the national gas grid, integrated seamlessly with existing natural gas supplies.

“Sewage Sludge at Minworth STW …

Injection into the UK Natural Gas Grid

Injecting biomethane into the national gas grid involves stringent quality standards to ensure safety and compatibility with existing infrastructure. Minworth Biogas adheres to these standards through meticulous monitoring and control systems.

Key Steps in Gas Grid Injection:

- Quality Assurance: Continuous testing for gas purity and composition to meet regulatory requirements.

- Metering and Monitoring: Real-time data collection on gas flow and pressure to maintain optimal injection conditions.

- Integration: Coordination with national grid operators to manage supply and demand dynamics effectively.

“Pipeline Injection Of Biomethane In …” from www.biocycle.net and used with no modifications.

Diagram: The process of injecting biomethane into the gas grid

Environmental and Economic Benefits

The Minworth Biogas project delivers a multitude of environmental and economic advantages, reinforcing its role as a sustainable energy solution.

Environmental Benefits:

- Reduction in Greenhouse Gas Emissions: Biomethane replacing natural gas lowers the carbon footprint.

- Waste Diversion: Significant reduction in organic waste sent to landfills, mitigating methane emissions from decomposition.

- Renewable Energy Production: Contributes to the UK's renewable energy targets and enhances energy resilience.

Economic Benefits:

- Job Creation: Generates employment opportunities in biogas production, maintenance, and management.

- Local Economy Support: Stimulates economic growth through local sourcing of organic waste and energy distribution.

- Energy Cost Savings: Provides a cost-effective alternative to fossil fuels, potentially lowering energy prices for consumers.

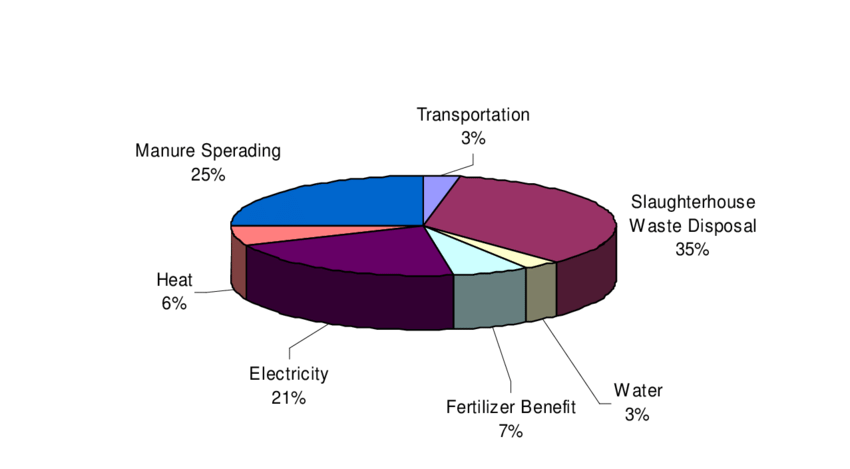

“economic benefit from the biogas plant …” from www.researchgate.net and used with no modifications.

Future of Biomethane in the UK's Energy Mix

The success of the Minworth Biogas facility paves the way for widespread adoption of biomethane across the UK. Future developments are likely to focus on scaling up production, enhancing technology, and expanding the range of feedstocks to further boost biomethane availability.

Prospects for Biomethane:

- Increased Production Capacity: Expansion of existing facilities and establishment of new plants to meet growing demand.

- Technological Advancements: Innovations in AD technology to improve efficiency and reduce costs.

- Policy Support: Government initiatives and incentives promoting renewable natural gas adoption.

Insert Image: Conceptual map of national biomethane expansion

How to Get Involved

Severn Trent invites stakeholders, communities, and businesses to participate in the journey towards a sustainable energy future. Whether through investment, collaboration, or adopting biomethane in your energy portfolio, there are numerous opportunities to contribute.

Ways to Engage:

- Invest in Biomethane Projects: Support the development and expansion of renewable energy infrastructure.

- Collaborate on Waste Management: Partner with Severn Trent to supply organic waste for biogas production.

- Adopt Renewable Energy Solutions: Transition to biomethane for heating and energy needs in residential and commercial settings.

Learn More About Investing in Biomethane

Anaerobic Digestion Gas to Grid – Biomethane Gas-Main Injection in England

Conclusion

Severn Trent's pioneering Minworth Biogas facility demonstrates the transformative potential of anaerobic digestion and biomethane in the UK's energy landscape. By successfully injecting renewable biomethane into the national gas grid, Minworth Biogas sets a vital example of sustainable innovation, paving the way for a greener, more resilient energy future.

Embracing such initiatives is essential for achieving national and global climate goals, reducing reliance on fossil fuels, and fostering a sustainable economy. As the first of its kind in the UK, Minworth Biogas not only highlights the feasibility of biomethane production but also inspires confidence in the widespread adoption of renewable natural gas as a key component of the UK's energy strategy.

Insert Image: Team at Minworth Biogas celebrating the grid injection milestone

Join Severn Trent in revolutionizing energy with biomethane. Together, we can create a sustainable and prosperous future for generations to come.

Our original post on this subject which we originally published in December 2016 follows:

Anaerobic Digestion Gas to Grid – Severn Trent Minworth Biogas 1st in the UK

In a move toward sustainability, Britain now has its first Anaerobic Digestion Gas to Grid project up and running, with the Severn Trent Minworth Biogas plant being the nation's first to inject biomethane into the UK's natural gas grid.

This is a major development. Severn Trent Water, are a major water and waste utility situated in the middle of the UK. They are now very much a leader when it comes to delivering Anaerobic Digestion gas to the grid. They run their operation from the Midlands. They serve the area around Birmingham, and also out into Wales.

A major part of their business that they're growing at the moment is renewable energy production. They have a number of UK anaerobic digestion plant sites.

These total around about 35, and are installed across the UK Midlands where they treat sewage sludge. They utilize the sludge to create electrical power by making use of Combined Heat and Power (CHP) engines. The engines generate electricity from the biomethane which their anaerobic digestion plants produce by upgrading their biogas output.

50 Years of Anaerobic Digestion

At their site in Minworth, they have been generating biogas for about 50 years from anaerobic digestion of their water treatment works sludge. However, nowadays they use the digestion processes on-site to produce biogas that is further purified and compressed so that it can be directly injected into the UK's national natural gas grid.

The technique is called “Anaerobic Digestion gas to grid” and it is greening the UK natural gas grid with gas consumers able to buy this “Renewable Natural Gas”.

For many years they have actually fed the biogas out into CHP engines that have actually allowed them to generate electrical power. This was previously only used to power the wastewater treatment site itself, and feed the regional electrical energy grid with the surplus power.

However, since 2011 they have established a better (more efficient and more sustainable) alternative to this and started by looking at updating their biogas systems and injecting it out into the National Grid.

The gas to-grid injection is done through the nearby natural gas main in the road outside the AD Plant.

Minworth UK First to Upgrade to Anaerobic Digestion Gas to Grid

The Severn Trent site at Minworth was the first to upgrade biogas from sewage treatment works, to provide Renewable Natural Gas (RNG) to the gas grid. They do not have a great level of control over their feedstock and exactly what's entering the Wastewater Treatment site. The result of that is that the biogas contains some substances which are impurities, and these cannot be injected into the natural gas main.

So they have a number of procedural actions that they've put in place to treat that gas and create the maximum effectiveness. In the primary step, they will look at removing a lot of the unstable natural compounds that they have in the gas that's coming off their digestion plant.

The anaerobic digestion plant is quite old. It's a basic mesophilic digester. It produces biogas that can consist of impurities. One unwanted compound is low quantities of siloxanes which trigger problems for combustion plants.

Impurities Must be Removed to Produce Anaerobic Digestion Gas to Grid

These cannot be allowed to go into the gas supply network, with other substances from deodorants that they might find in hair shampoos or shower gels that could cause an impact on the gas as it moves through the system and is used. Severn Trent Water engineers eliminate these impurities with an activated carbon treatment system at the front of the procedure. That means that they can proceed with the real task of upgrading the biogas.

This is done, as elsewhere at the growing number of other anaerobic digestion gas to grid (biomethane) wastewater treatment (sewage works) sites around the UK. At Minworth, they have decided to make use of a water scrubbing plant. They have done this since they've seen it running on a variety of anaerobic digestion gas to grid sites on the continent where they were able to see the sewage sludge being bio digested. They were also able to see it being upgraded in volume, at the flows and the quantities that they desired.

There are a variety of innovations that biogas digester operators can use, but because of the irregularity of the quality of their feedstock and the variability of the biogas that they produce, the water scrubber is the most resilient technology to use to clean up their biogas. It has worked well, and they have found it to be an excellent addition to their portfolio.

At Minworth Wastewater Treatment Works they were also the very first site in the UK that injected “anaerobic digestion gas to grid”. It is injected into the regional transmission system. That implies that the gas must be pressurised to the National Grid's somewhat higher pressure system of in-between 15 and 20 bar gauge pressure.

Upping the Pressure to Push the Biogas to Grid

What that needed was for them to introduce new compression plants onto the site and brand-new gas quality monitoring equipment was also added to keep a check on the biogas (biomethane) quality achieved. Once they've cleaned that biogas and they've got it to around 97/98% methane, they then compress it before they pump it out into the National Grid.

This gas is now 100% ready to enter into the grid and they have the necessary gas quality monitoring system where they run some checks and keep track of the quality of that gas continuously. They must be absolutely certain of the high quality of that biomethane prior to passing it under the roadway into the local transmission system.

National Grid take it away from there for usage in the domestic network, so they now get a considerably higher performance as far as energy efficiency and sustainability than they've had the ability to attain previously.

The biomethane upgrading process has actually been an exceptionally successful addition to their energy portfolio. At the time of writing (recording their video), they had run it for nine months with very few problems subsequent to completing commissioning. In fact, they report that they have injected around about 40GW hrs of eco-friendly biomethane gas.

This gas is roughly enough to heat 3,000 UK houses, but exactly what they utilize it for is reducing their gas usage as a company and they now intend to be entirely self-adequate in the gas that they utilize to run their entire utility service every day.

[Originally published in December 2016. Updated October 2021 and May 2025.]