Strategies for Decarbonization Using Biogas Renewable Energy

Key Takeaways

- Biogas technology can transform organic waste into renewable energy while reducing greenhouse gas emissions by up to 85%, making it one of the most effective decarbonization strategies available.

- Agricultural waste, particularly manure, offers the highest carbon reduction potential among biogas feedstocks, with potential savings of 90-120 gCO2e/MJ compared to fossil natural gas.

- A billion cubic meters of biomethane can lead to 2.33-4.37 MtCO2e savings, depending on feedstock mix and application, demonstrating significant climate impact at scale.

- Biogas systems create closed-loop energy cycles that support agricultural resilience while providing multiple revenue streams through energy production, carbon credits, and nutrient recovery.

- Energy Independence Systems provides comprehensive biogas implementation strategies that help organizations transition from fossil fuels to renewable energy while creating economic advantages.

What Makes Biogas a Powerful Tool for Decarbonization

Biogas stands out as a remarkably versatile renewable energy source that tackles multiple environmental challenges simultaneously. Unlike other renewable energy solutions that simply replace fossil fuels, biogas transforms problematic waste streams into valuable energy while preventing powerful greenhouse gases from entering the atmosphere.

This dual-action approach creates a unique opportunity where implementing biogas solutions can actually result in negative carbon emissions in certain applications, particularly when capturing methane that would otherwise be released during natural decomposition processes. Energy Independence Systems has pioneered methods that maximise this carbon-negative potential through optimised waste-to-energy pathways, making biogas an essential component of comprehensive decarbonization strategies.

The Organic Waste Problem Biogas Solves

Every year, billions of tons of organic waste decompose and release methane—a greenhouse gas at least 28 times more potent than carbon dioxide over a 100-year period.

Agricultural operations, food processing facilities, and municipal waste management systems all face the challenge of responsibly handling organic materials while minimising environmental impact. When left untreated in traditional systems, this waste creates significant methane emissions through anaerobic decomposition in landfills or open storage lagoons.

Biogas production intervenes in this process by capturing the methane before it reaches the atmosphere, converting a potential environmental liability into a valuable energy resource that displaces fossil fuels.

The scale of the opportunity is immense—virtually any operation that generates organic waste can potentially benefit from biogas technology. From small rural farms to massive urban waste treatment facilities, the decentralized nature of biogas production allows implementation across diverse settings and scales.

Additionally, by diverting organic waste from landfills, biogas systems reduce the burden on waste management infrastructure while extending the useful life of existing disposal facilities.

“Integration of biogas systems into a …” from link.springer.com and used with no modifications.

How Biogas Offers Decarbonization Strategies with Carbon-Negative Potential

The most compelling aspect of biogas as a decarbonization tool lies in its potential to achieve carbon-negative outcomes—actually removing more greenhouse gases than it produces.

This remarkable capability stems from biogas's unique position in capturing methane emissions that would otherwise enter the atmosphere during natural decomposition processes. When agricultural manure is processed through anaerobic digestion, for example, the methane that would have been released during conventional storage is instead captured and utilised, creating an emission reduction of 90-120 gCO2e/MJ compared to fossil natural gas.

This carbon-negative potential is most pronounced when processing agricultural waste, particularly manure from dairy and swine operations. Research from the California Air Resources Board demonstrates that renewable natural gas (RNG) produced from dairy manure can achieve carbon intensities as low as -250 to -300 gCO2e/MJ—far below the carbon intensity of any fossil fuel and even lower than most other renewable energy sources.

The negative values indicate that the process removes more greenhouse gases than it generates throughout its lifecycle, making it an extraordinarily powerful tool for organisations seeking aggressive decarbonization outcomes.

Beyond the direct carbon benefits, biogas systems create multiple positive environmental impacts through improved waste management practices.

By controlling the decomposition process, these systems reduce odors, prevent water contamination, and produce nutrient-rich digestate that can replace synthetic fertilisers—each contributing additional carbon reduction benefits that compound the already impressive climate performance.

How Biogas Compares to Other Decarbonization Strategies

When evaluating renewable energy options, biogas offers distinct advantages that complement other decarbonization strategies, such as solar, wind, and electrification. While solar and wind provide intermittent power based on weather conditions, biogas delivers consistent, on-demand energy that can be stored and dispatched when needed. This reliability makes biogas particularly valuable for industrial applications requiring continuous process heat or backup power generation capacity. Furthermore, biogas can be upgraded to biomethane (renewable natural gas) and injected into existing natural gas infrastructure, allowing organisations to leverage billions in existing assets rather than requiring completely new distribution systems.

The emissions profile of biogas also distinguishes it from other renewable strategies. Electrification only reduces emissions to the extent that the underlying electricity grid is decarbonised, while biogas can achieve immediate and substantial emission reductions regardless of grid mix. In transportation applications, biomethane can reduce emissions by 50-300% compared to diesel fuel, depending on the feedstock used. This exceptional performance explains why transportation companies with ambitious climate goals are increasingly turning to biomethane as a strategic component of their decarbonization plans.

![]()

“Biohydrogen with negative CO2 emissions …” from www.sciencedirect.com and used with no modifications.

5 Main Sources of Biogas Production with Global Decarbonization Potential

Biogas production can leverage diverse organic materials, each offering different carbon reduction potentials and implementation considerations. Understanding these feedstock options is crucial for organisations developing effective decarbonization strategies that maximise both environmental and economic benefits. The carbon intensity of biogas varies significantly based on feedstock source, with agricultural waste offering the most dramatic climate benefits and landfill gas providing more modest but still substantial emissions reductions.

1. Agricultural Waste and Manure

Agricultural waste, particularly animal manure, represents the biogas feedstock with the highest decarbonization potential. When manure is stored in conventional lagoons or pits, it naturally releases methane directly into the atmosphere. By capturing this methane through anaerobic digestion, agricultural biogas systems prevent these emissions while simultaneously producing renewable energy.

Dairy manure typically delivers the largest emission reduction due to the avoided methane emissions that would otherwise occur if the manure were not digested. Studies from Argonne National Laboratory demonstrate that dairy-derived renewable natural gas can achieve carbon intensity scores between -250 and -300 gCO2e/MJ, making it among the most carbon-negative energy sources available today.

2. Food Processing Byproducts

Food processing facilities generate substantial volumes of organic waste that make excellent biogas feedstock. These materials include fruit and vegetable trimmings, expired products, production wastewater, and various manufacturing byproducts.

Unlike manure, these feedstocks typically don't emit significant methane during conventional disposal, but they still offer impressive carbon reduction benefits when converted to biogas. Food waste-derived renewable natural gas typically achieves carbon intensities of 20-40 gCO2e/MJ, representing a 60-80% reduction compared to fossil natural gas.

The food and beverage industry has been quick to adopt biogas technology as part of its decarbonization strategies, recognising both the environmental benefits and the economic advantages of converting waste streams into energy.

Companies that implement on-site biogas systems can simultaneously reduce waste disposal costs, lower energy bills, and shrink their carbon footprint—creating a compelling triple-bottom-line case for investment. Additionally, using biogas derived from food processing waste creates a circular economy narrative that resonates with environmentally conscious consumers and stakeholders.

3. Municipal Solid Waste

The organic fraction of municipal solid waste represents a vast, largely untapped resource for biogas production. When diverted from landfills to anaerobic digesters, food scraps, yard waste, and other biodegradable materials can generate significant quantities of renewable energy while reducing methane emissions from landfills. Municipal waste-derived biogas typically achieves carbon intensities around 40-50 gCO2e/MJ, representing approximately a 50% reduction compared to fossil natural gas.

Cities and municipalities increasingly view biogas as a strategic component of sustainable waste management systems. By implementing source-separated organic collection programs and constructing biogas facilities, communities can reduce landfill volumes, cut greenhouse gas emissions, and generate renewable energy—all while creating local jobs and economic development opportunities. These systems demonstrate how thoughtful infrastructure planning can transform waste management from an environmental liability into a climate solution that generates both energy and economic value.

“Unlocking decarbonisation by 2030: Why …” from www.gasworld.com and used with no modifications.

4. Wastewater Treatment Plants

Wastewater treatment facilities have been early adopters of biogas technology, capturing methane from sewage sludge to power their operations. The organic matter in municipal and industrial wastewater provides a consistent, predictable feedstock for anaerobic digestion, making these facilities ideal candidates for biogas production. Wastewater-derived biogas typically achieves carbon intensities of 30-40 gCO2e/MJ, representing a significant improvement over fossil fuels while helping treatment plants reduce their operational costs and energy dependence.

The integration of biogas production into wastewater infrastructure exemplifies how essential public services can be reimagined to contribute to climate solutions. Forward-thinking utilities have transformed their treatment plants from energy consumers to energy producers by maximizing biogas production and installing efficient generation equipment. These projects demonstrate how existing infrastructure can be leveraged to advance decarbonization goals without requiring entirely new systems or technologies.

5. Landfill Gas Capture Systems

Landfills naturally generate methane as organic waste decomposes in anaerobic conditions beneath layers of trash. Landfill gas capture systems collect this methane through networks of wells and pipes, preventing its release to the atmosphere and enabling its use as an energy source.

While landfill gas offers the lowest carbon reduction potential among biogas sources (typically 50-60 gCO2e/MJ compared to 90-100 gCO2e/MJ for fossil natural gas), it still represents a significant improvement over allowing the methane to escape directly to the atmosphere.

The widespread implementation of landfill gas systems demonstrates how even modest infrastructure investments can yield substantial climate benefits when applied to large-scale emission sources. With thousands of active and closed landfills worldwide, this approach offers immediate decarbonization opportunities using proven technology and established project development models. Moreover, landfill gas projects often represent the most economically accessible biogas opportunity, providing an entry point for organisations beginning their journey toward more comprehensive renewable energy strategies.

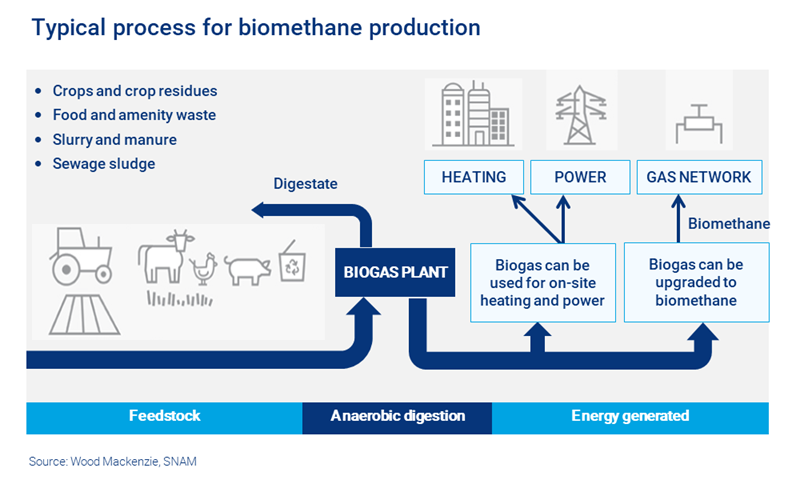

The Biogas-to-Energy Conversion Processes with Decarbonization Potential

Converting organic waste into usable energy involves several technological processes that can be optimized for specific applications and decarbonization objectives. Understanding these conversion pathways helps organizations identify the most appropriate biogas implementation strategy for their particular circumstances, whether prioritizing maximum carbon reduction, lowest cost, or specific energy outputs.

The flexibility of biogas systems allows customization to meet diverse organizational needs while delivering meaningful climate benefits.

Anaerobic Digestion: Breaking Down Organic Matter

At the heart of biogas production lies anaerobic digestion—a biological process where microorganisms break down organic materials in the absence of oxygen. This process occurs within sealed vessels called digesters, which maintain optimal conditions for the microbial communities that transform complex organic compounds into biogas.

Different digester designs accommodate various feedstocks and operating conditions, from simple covered lagoons for animal manure to sophisticated continuously stirred tank reactors for food waste and industrial byproducts.

The efficiency of anaerobic digestion directly impacts both the economic and environmental performance of biogas systems. Advanced digester designs can increase methane yields by 25-40% compared to basic systems, dramatically improving project economics while maximising carbon benefits.

Innovations in pre-treatment technologies further enhance performance by increasing the biodegradability of feedstocks, unlocking additional energy potential from recalcitrant materials like lignocellulosic biomass. These technological advances continually improve the cost-effectiveness of biogas as a decarbonization strategy.

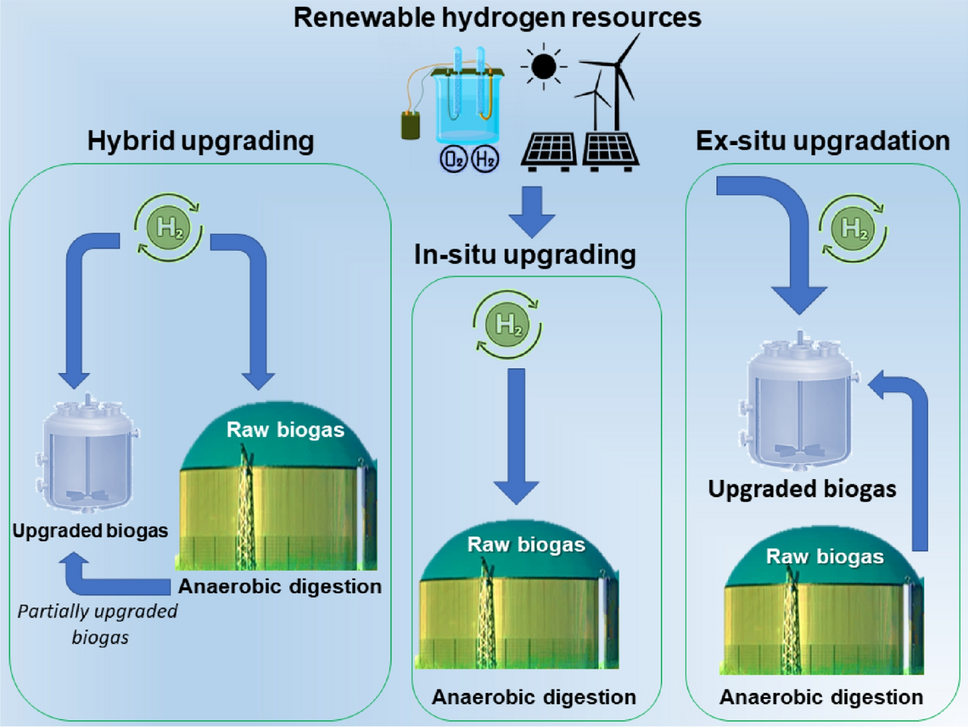

Biogas Cleaning and Upgrading to Biomethane

Raw biogas contains approximately 50-65% methane, with the remainder primarily being carbon dioxide, along with trace contaminants like hydrogen sulfide and siloxanes. For many applications, particularly pipeline injection or vehicle fuel, this biogas must be cleaned and upgraded to biomethane (also called renewable natural gas or RNG) with 95%+ methane content.

Multiple upgrading technologies exist, including water scrubbing, pressure swing adsorption, membrane separation, and chemical absorption, each offering different efficiency and cost profiles for specific project conditions.

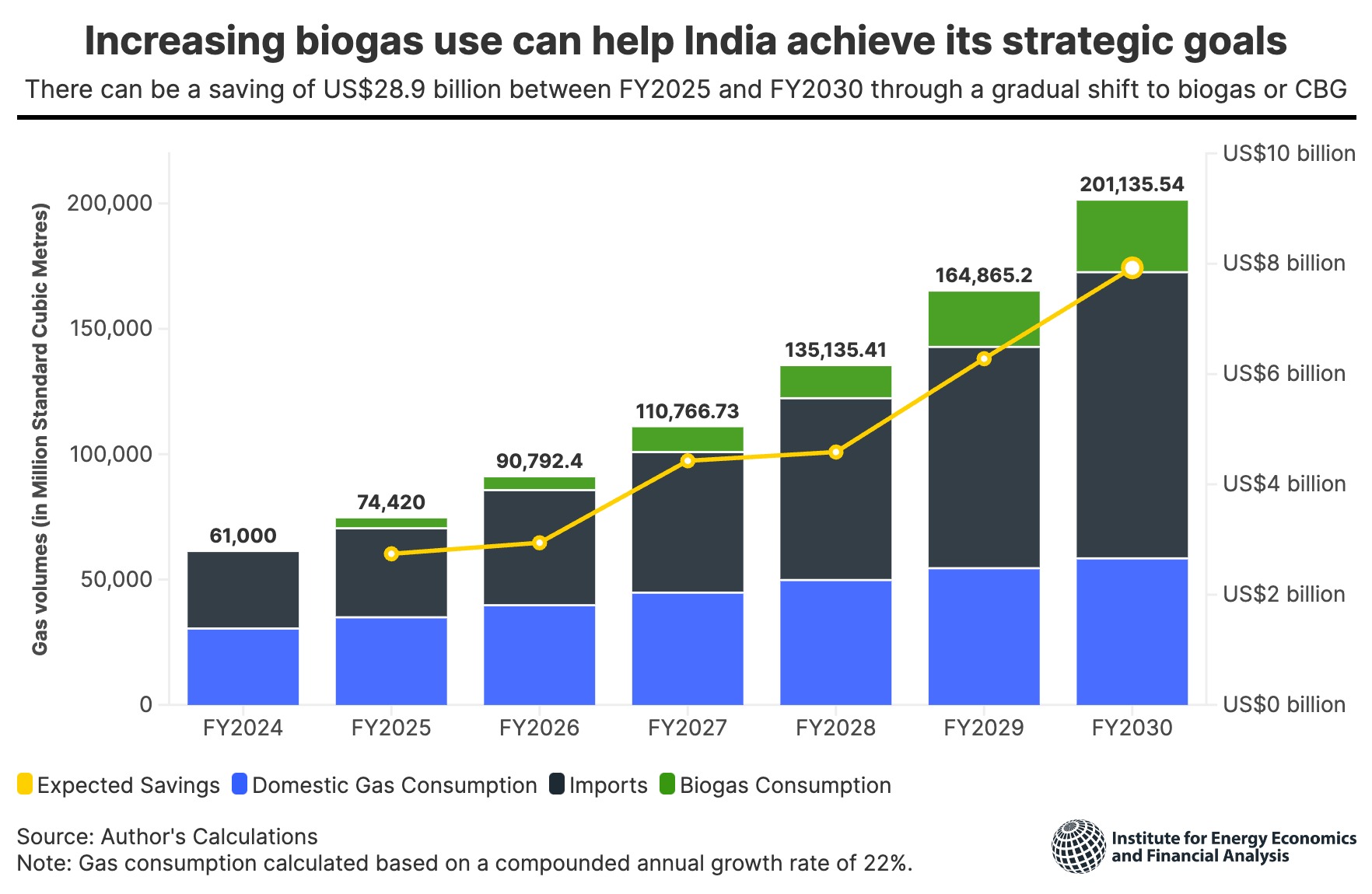

“Greater use of biogas can help India …” from ieefa.org and used with no modifications.

Biogas Cleaning and Upgrading to Biomethane

The upgrading process transforms raw biogas into biomethane by removing carbon dioxide and trace contaminants, creating a purified product that's completely interchangeable with conventional natural gas. This versatility allows biomethane to leverage existing natural gas infrastructure, including pipelines, storage facilities, and end-use equipment, without modification.

The carbon intensity of biomethane varies significantly based on feedstock source, with dairy manure-derived biomethane potentially achieving carbon intensities below -250 gCO2e/MJ, while landfill gas typically ranges from 50-60 gCO2e/MJ.

Upgrading technologies continue to advance, reducing both capital costs and energy requirements while improving methane recovery rates. Modern systems can achieve methane recoveries exceeding 99%, minimising both economic losses and fugitive methane emissions that could otherwise diminish climate benefits.

These technological improvements have helped reduce biomethane production costs by approximately 30% over the past decade, enhancing the economic case for biogas as a decarbonization strategy across more applications and markets.

Comparative Carbon Intensity of Energy Sources (gCO2e/MJ)

Dairy Manure Biomethane: -250 to -300

Food Waste Biomethane: 20-40

Wastewater Biomethane: 30-40

Landfill Gas Biomethane: 50-60

Conventional Natural Gas: 90-100

Diesel Fuel: 95-105

Combined Heat and Power Generation

One of the most efficient decarbonising applications for biogas is combined heat and power (CHP) generation, where the gas fuels an engine or turbine to produce electricity while capturing waste heat for thermal applications.

CHP systems can achieve overall efficiencies of 80-90%, significantly higher than separate heat and power generation. This exceptional efficiency translates directly to improved carbon performance, as more useful energy is extracted from each unit of biogas, maximising the displacement of fossil fuels and their associated emissions.

CHP systems are particularly valuable in industrial settings where both electricity and process heat are required, or in district energy systems serving multiple buildings or facilities. The reliability of biogas makes these systems ideal for continuous operation, providing baseload renewable energy that complements intermittent sources like solar and wind.

Modern CHP units offer remarkable flexibility, with rapid ramping capabilities that allow them to adjust output based on demand or to compensate for fluctuations in other renewable sources, creating a more resilient and balanced energy system.

Top Industrial Decarbonization Applications for Biogas

Industrial energy use accounts for approximately one-third of global greenhouse gas emissions, making it a critical frontier for decarbonization efforts. Many industrial processes require high-temperature heat that's challenging to electrify, creating a natural fit for biomethane as a low-carbon alternative to conventional natural gas.

The flexible nature of biogas systems allows customisation to meet specific industrial requirements, whether prioritising continuous heat production, electricity generation, or feedstock for chemical processes.

Forward-thinking companies are increasingly integrating biogas into their sustainability strategies, recognising both the immediate emission reductions and the potential for achieving carbon neutrality or even carbon negativity in certain applications.

The ability to produce renewable energy from waste streams creates powerful circularity narratives that resonate with consumers, investors, and other stakeholders increasingly focused on environmental performance and sustainable business practices.

Replacing Natural Gas in Manufacturing

Manufacturing processes that rely on natural gas for thermal energy represent prime opportunities for biomethane substitution and decarbonization. Food processing, beverage production, textile manufacturing, and ceramics all require substantial thermal inputs that can be readily supplied by upgraded biogas.

Since biomethane is chemically identical to conventional natural gas, this substitution requires no modifications to existing equipment or processes, allowing for seamless transition without disrupting operations.

The climate impact of this substitution varies based on the biomethane source, with potential emission reductions ranging from 50% to over 300% compared to fossil natural gas.

Manufacturers with ambitious sustainability goals increasingly seek agricultural waste-derived biomethane specifically for its carbon-negative profile, allowing them to make substantial progress toward net-zero targets without fundamental process changes.

This approach represents a pragmatic decarbonization pathway that balances immediate climate action with practical operational considerations and economic constraints.

On-Site Energy Generation for Factories

Factories that generate organic waste through their operations have unique opportunities to implement on-site biogas systems, creating closed-loop energy production that reduces both waste management costs and energy expenses.

Food and beverage producers, paper mills, and agricultural processors can capture value from what was previously a disposal challenge, generating electricity, heat, and even cooling through absorption chiller systems powered by biogas. These integrated systems enhance resilience by reducing dependence on external energy supplies while dramatically cutting carbon emissions. Learn more about biogas systems and their impact on sustainable energy solutions.

On-site systems also eliminate the carbon footprint associated with waste transport and processing, further improving environmental performance. Companies implementing these solutions frequently report payback periods of 3-7 years on their investments, with subsequent decades of reduced operating costs and enhanced sustainability metrics.

The visible nature of on-site biogas infrastructure also creates a tangible demonstration of sustainability commitment that resonates with visitors, employees, and community stakeholders.

“Can Biomethane Decarbonise Europe's Gas …” from www.woodmac.com and used with no modifications.

Biogas as Feedstock for Green Chemical Production

Beyond direct energy applications, biomethane can serve as a renewable feedstock for chemical manufacturing, replacing fossil natural gas in the production of hydrogen, methanol, and other industrial chemicals.

This approach enables decarbonization of chemical supply chains without requiring fundamental process redesigns or unproven technologies. The carbon reduction potential is particularly significant for hydrogen production, where biomethane reforming can achieve carbon intensities 50-300% lower than conventional natural gas reforming, depending on the biomethane source.

Chemical producers increasingly view biomethane as a strategic bridge technology that allows meaningful decarbonization using existing assets and expertise, while longer-term solutions like green hydrogen from electrolysis mature technically and economically.

This pragmatic approach maintains production capabilities and business continuity while steadily reducing environmental impact. As carbon pricing mechanisms and sustainable product certification schemes become more prevalent, the economic case for biomethane in chemical production continues to strengthen, accelerating adoption across the industry.

Transportation Sector Decarbonization with Biogas

The transportation sector presents unique decarbonization challenges, particularly for heavy-duty and long-distance applications where battery electrification faces significant hurdles.

Renewable natural gas (RNG) offers an immediate decarbonization pathway for these challenging segments, leveraging existing vehicle technologies and fueling infrastructure while delivering substantial emission reductions.

Research demonstrates that a billion cubic meters of biomethane can lead to 2.33-4.37 MtCO2e savings in transport applications, depending on the feedstock mix and specific use cases.

Renewable Natural Gas (RNG) for Vehicle Fleets

Fleet operators across multiple sectors have emerged as early adopters of RNG, recognising both the environmental benefits and the operational advantages of natural gas vehicles. Waste collection companies, municipal bus services, and delivery fleets increasingly power their operations with RNG, typically achieving 50-300% carbon reductions compared to diesel, depending on the biomethane source. These fleets benefit from stable fuel pricing, quieter vehicle operation, and significantly reduced emissions of both greenhouse gases and local air pollutants like particulate matter and nitrogen oxides.

The growing network of natural gas fueling infrastructure supports fleet transitions to RNG, with over 1,600 stations now operating across North America and continued expansion in Europe.

The minimal operational changes required when transitioning from diesel to natural gas vehicles, coupled with the dramatic carbon reductions possible with RNG, make this approach particularly attractive for organisations seeking substantial near-term climate progress.

Biomethane in Heavy Transport and Shipping

Heavy-duty trucking and maritime shipping represent particularly challenging decarbonization sectors where biomethane offers viable pathways to significant emission reductions.

Long-haul trucking operations have demonstrated successful transitions to compressed natural gas (CNG) and liquefied natural gas (LNG) vehicles fueled by RNG, achieving both operational reliability and environmental benefits.

When powered by dairy-derived RNG, these vehicles can achieve carbon intensities over 200% lower than their diesel counterparts, effectively making each mile driven carbon-negative.

In maritime applications, LNG has gained traction as a cleaner alternative to conventional bunker fuels, with biomethane offering a pathway to dramatically reduce the climate impact of this growing LNG fleet. Major shipping companies have begun incorporating biomethane into their fuel mix, typically through book-and-claim systems that match physical natural gas consumption with biomethane production elsewhere in the supply chain.

This approach allows immediate carbon reductions without requiring new vessel technologies or port infrastructure, creating a practical bridge to the industry's longer-term decarbonization ambitions.

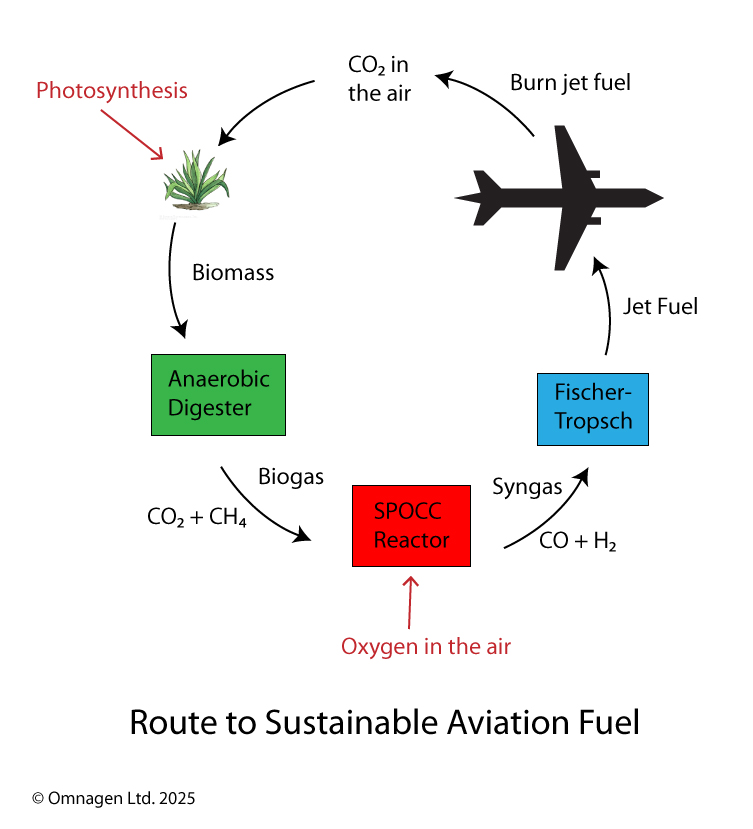

Aviation Fuel Alternatives from Biogas

While direct use of biogas in aviation remains limited, innovative pathways are emerging to convert biomethane into sustainable aviation fuels (SAF) compatible with existing aircraft and infrastructure.

These processes typically involve reforming biomethane into syngas, followed by Fischer-Tropsch synthesis to create liquid hydrocarbons suitable for jet engines. The carbon intensity of these fuels depends primarily on the biomethane source, with agricultural waste-derived pathways offering the most substantial climate benefits.

Airlines and fuel producers have begun exploring these biogas-to-SAF pathways as part of broader efforts to reduce aviation's climate impact. The ability to leverage existing biogas production infrastructure creates opportunities to scale SAF production more rapidly than alternatives requiring entirely new feedstock supply chains.

While still emerging, these technologies demonstrate how biogas can contribute to decarbonization even in sectors not directly equipped to use gaseous fuels, highlighting the versatility of this renewable energy source as part of comprehensive climate strategies.

“Sustainable Aviation Fuel” from clean-carbonenergy.com and used with no modifications.

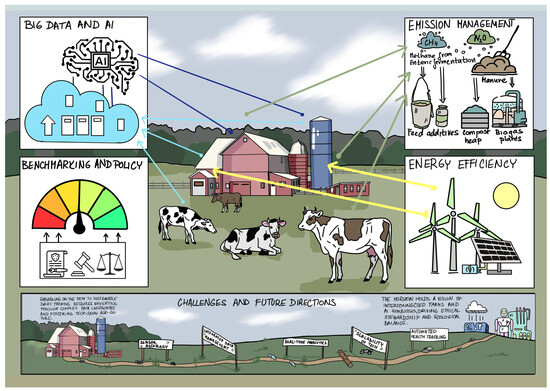

Agricultural Closed-Loop Systems: The Ultimate Carbon Reducer

Perhaps the most powerful application of biogas technology is in agricultural settings, where anaerobic digesters create truly circular energy and nutrient cycles. These systems capture methane from manure and other agricultural wastes, preventing powerful greenhouse gas emissions while producing renewable energy and nutrient-rich fertilizer.

The integrated nature of these systems delivers compound benefits across multiple dimensions—climate, energy, waste management, and agricultural productivity—creating some of the most compelling decarbonization opportunities available today.

Farm-Based Digesters Creating Energy Independence

Agricultural operations implementing biogas systems often achieve remarkable levels of energy independence, producing sufficient electricity and heat to power their entire operations with excess available for export to the grid.

This transformation from energy consumer to energy producer dramatically improves farm economics while reducing carbon footprints. Modern farm digesters incorporate sophisticated monitoring and control systems that optimize biological processes for maximum methane production, increasing energy yields while ensuring stable, reliable operation.

Beyond the direct energy benefits, farm-based biogas systems significantly improve waste management practices, reducing odours, pathogens, and potential water contamination issues associated with conventional manure handling.

These environmental improvements enhance community relations and often simplify regulatory compliance, providing valuable co-benefits alongside the core energy and climate advantages. The resilience provided by on-site energy production has proven particularly valuable during grid outages and extreme weather events, allowing agricultural operations to maintain critical functions even when external power supplies are compromised.

Nutrient Recovery from Digestate

The digestate byproduct from agricultural biogas systems contains valuable nutrients, including nitrogen, phosphorus, and potassium, in forms more readily available to plants than raw manure.

Advanced nutrient recovery systems can separate these elements into concentrated products that replace synthetic fertilisers, creating additional carbon benefits by avoiding the emissions associated with conventional fertiliser production. The improved nutrient management also reduces runoff risks, protecting local water resources while maintaining or enhancing crop yields.

Progressive agricultural operations increasingly view digesters not simply as energy production systems but as comprehensive nutrient management platforms that create multiple value streams from what was previously considered waste.

The ability to precisely apply recovered nutrients according to crop needs improves agricultural efficiency while reducing environmental impact. This holistic approach exemplifies how thoughtfully designed biogas systems can simultaneously address multiple sustainability challenges while creating economic advantages for their operators.

Carbon Credits and Additional Revenue Streams

Farm-based biogas systems often qualify for carbon credits, renewable energy certificates, and other environmental commodities that create significant additional revenue streams beyond energy sales and tipping fees.

In certain jurisdictions, the value of these environmental attributes can exceed the value of the energy itself, particularly for dairy manure projects with extremely negative carbon intensities. These market-based incentives recognise the substantial climate benefits these systems deliver, creating financial rewards that improve project economics and accelerate adoption.

The layering of multiple revenue streams—energy sales, avoided energy purchases, tipping fees, fertiliser value, and environmental credits—creates resilient business models that can withstand fluctuations in any single value stream.

This economic diversification, combined with the operational benefits of improved waste management and energy independence, makes agricultural biogas systems among the most financially sustainable renewable energy investments available.

As carbon markets mature and expand globally, the economic case for these systems will likely strengthen further, driving increased implementation across diverse agricultural settings.

Real-World Success Stories: Biogas Decarbonization in Action

Across the globe, organisations are implementing biogas systems that deliver remarkable decarbonization results while creating economic and operational benefits. These real-world examples demonstrate the practical viability of biogas as a decarbonization strategy across diverse sectors and scales. By examining successful implementations, organisations can identify applicable models and approaches for their own circumstances, accelerating the transition to renewable energy while avoiding common pitfalls and implementation challenges.

How a Dairy Farm Cut Emissions by 85%

A 5,000-cow dairy operation in California implemented a covered lagoon digester system that captures methane from manure and converts it to renewable electricity and pipeline-quality biomethane. This system prevents approximately 25,000 metric tons of CO2 equivalent emissions annually while generating enough renewable energy to power 1,200 homes. The project qualified for California's Low Carbon Fuel Standard program, generating credits that provide substantial ongoing revenue beyond direct energy sales.

Beyond the climate benefits, the system has significantly reduced odour issues that had previously created tension with neighbouring communities. The nutrient-rich digestate has replaced synthetic fertilisers on surrounding cropland, creating additional environmental benefits while reducing input costs. Farm operators report that the project achieved financial payback in less than five years when accounting for all revenue streams and operational benefits, demonstrating the economic viability of agricultural biogas systems when properly designed and implemented.

“Net Zero Dairy Farming—Advancing …” from www.mdpi.com and used with no modifications.

Municipal Waste Programs That Generate Revenue

A mid-sized city in Sweden implemented a comprehensive organic waste collection program that diverts food scraps and yard waste to an anaerobic digestion facility producing biomethane for the municipal bus fleet. This system processes approximately 40,000 tons of organic waste annually, generating enough fuel to replace 1.2 million liters of diesel while reducing the city's carbon footprint by approximately 3,200 metric tons CO2e per year. The integrated approach has transformed waste management from a cost center to a revenue generator through avoided disposal fees, reduced fuel purchases, and carbon credits.

The visible nature of the program—with clearly branded waste collection vehicles and buses prominently advertising their use of locally-produced renewable fuel—has created strong community support and high participation rates in the organic waste separation program. This success has inspired neighbouring communities to implement similar systems, creating regional-scale efficiencies in both waste collection and biomethane production. The municipality reports that this approach costs approximately 15% less than their previous waste management system while delivering substantial environmental benefits, demonstrating the economic advantages of thoughtfully designed biogas programs.

Food Manufacturers Achieving Carbon Neutrality

A large European food manufacturer installed an on-site anaerobic digestion system that processes wastewater and solid organic residues from production lines, generating biogas that provides approximately 70% of the facility's thermal energy needs.

This system reduces natural gas consumption by over 500,000 cubic meters annually while preventing approximately 12,000 metric tons of CO2e emissions. The avoided energy costs and waste disposal savings deliver annual operating benefits exceeding €1.2 million, creating a compelling financial case alongside the environmental advantages.

The company has leveraged this installation as a cornerstone of its carbon neutrality strategy, using the substantial emission reductions to offset remaining unavoidable emissions from operations and transportation.

The visible commitment to sustainability has strengthened relationships with retail partners increasingly focused on supply chain emissions, while creating marketing advantages with environmentally conscious consumers. This implementation demonstrates how biogas can serve as a practical pathway to meaningful climate action for food producers, creating business advantages while delivering substantial environmental benefits.

The Economic Case for Biogas Energy Systems

While environmental benefits drive many biogas implementations, the economic advantages often prove equally compelling. Well-designed biogas systems create multiple revenue streams and cost savings that combine to deliver attractive financial returns alongside their climate benefits. The economic case varies significantly based on project scale, feedstock availability, energy prices, and regulatory environment, but continues to strengthen as technology improves and carbon reduction becomes increasingly valued in the marketplace.

Installation Costs vs. Long-Term Savings

Initial capital costs for biogas systems typically range from $1,500-$5,000 per kW of installed capacity, with economies of scale favouring larger implementations. While these upfront investments exceed those for some conventional energy systems, the ongoing operational advantages create compelling long-term economics.

Modern biogas systems achieve operational lifespans exceeding 20 years, with proper maintenance ensuring reliable performance throughout this period. When evaluated on a lifecycle basis that accounts for all costs and benefits over this operational period, biogas frequently emerges as the most economically attractive energy solution for organisations with suitable organic waste streams.

The economics become particularly favourable when accounting for multiple value stream,s including energy production, waste management savings, carbon credits, and nutrient recovery. Projects that effectively monetise all these components typically achieve payback periods between 3-7 years, with subsequent decades of positive cash flow.

As carbon pricing mechanisms expand globally and fossil fuel costs face increasing volatility, the economic case for biogas continues to strengthen, accelerating adoption across diverse sectors and applications.

Frequently Asked Biogas Decarbonization Questions

As interest in biogas continues to grow, potential implementers naturally have questions about practical aspects of these systems and their performance in real-world conditions. The following responses address common inquiries based on operational experience and current market conditions, providing actionable insights for organizations considering biogas as part of their decarbonization strategies.

How much does a biogas system typically cost to install?

Biogas system costs vary significantly based on scale, technology, and application. Small farm-based systems processing manure from 500-1,000 cows typically require investments of $1-3 million, while large commercial facilities processing diverse feedstocks can exceed $20 million. On a unit basis, costs generally range from $1,500-$5,000 per kilowatt of installed electrical capacity or $3-10 per standard cubic foot of daily biogas production. Economies of scale significantly impact these figures, with larger systems generally achieving lower unit costs. Advanced features like biogas upgrading to biomethane add approximately 30-50% to base system costs but create additional value streams that often justify this investment.

Can small farms benefit from biogas technology?

Yes, though the approach differs from larger implementations. Farms with 200-500 animal units can implement appropriately scaled digester systems, particularly using covered lagoon or plug-flow designs that minimise capital costs.

Cooperative models where multiple small farms send material to a centralised digester have proven successful in many regions, allowing smaller operations to achieve the scale efficiencies that improve project economics.

Simplified designs specifically targeting smaller operations have entered the market in recent years, reducing both capital requirements and operational complexity while still delivering meaningful environmental and operational benefits.

What percentage of carbon emissions can biogas systems reduce?

Carbon reduction from biogas systems ranges from 50% to over 300% compared to fossil alternatives, depending primarily on feedstock source. Systems processing agricultural manure typically achieve the highest reduction percentages due to avoided methane emissions from conventional manure storage.

Food waste systems generally reduce emissions by 60-80% compared to fossil fuels, while landfill gas systems achieve approximately 50-60% reductions. These figures represent lifecycle assessments accounting for all emissions associated with feedstock collection, processing, and energy production, providing an accurate representation of real-world climate impacts.

How does biogas compare to solar and wind energy?

While solar and wind generate electricity with minimal ongoing emissions, biogas offers distinct advantages, including continuous availability, waste management benefits, and potential for carbon-negative performance with certain feedstocks.

Unlike intermittent renewables that depend on weather conditions, biogas provides dispatchable power that can be produced on demand, making it valuable for baseload energy needs and grid stability. The methane capture aspect of biogas systems can prevent potent greenhouse gas emissions that would otherwise occur during natural decomposition, creating climate benefits beyond simply displacing fossil fuels.

Rather than competing alternatives, biogas, solar, and wind represent complementary technologies that address different aspects of our energy system. Many organisations implement combinations of these renewables to create integrated systems that leverage the strengths of each approach. The specific mix depends on local resources, energy requirements, and operational considerations, with biogas particularly valuable where organic waste management aligns with energy needs.

Are there limitations to using biogas for decarbonization?

The primary limitation for biogas is feedstock availability, as production depends on accessible organic waste streams. While substantial untapped potential exists globally, biogas cannot completely replace current fossil fuel consumption due to finite sustainable feedstock supplies.

Geographic distribution of feedstocks also creates challenges, as transportation costs can undermine both economic and environmental performance if materials must travel long distances to processing facilities. To address these challenges, exploring anaerobic digestion feedstock pre-treatment methods can enhance the efficiency and viability of biogas production.

Operational complexity represents another consideration, as biogas systems require more active management than some other renewable technologies. Biological processes demand monitoring and occasional intervention to maintain optimal performance, particularly when processing variable feedstocks. This complexity necessitates either staff with appropriate training or service agreements with experienced providers who can ensure system stability and performance.

Capital intensity presents a barrier for some organisations, as biogas systems typically require larger initial investments than some alternative approaches. While lifecycle economics often prove favourable, the upfront costs can challenge organisations with limited capital budgets or competing investment priorities. Various financing mechanisms have emerged to address this limitation, including energy service agreements, build-own-operate models, and specialised biogas investment funds that reduce or eliminate upfront capital requirements.