Key Takeaways

- Denmark's biogas cooperative model has transformed agricultural waste into a renewable energy source that now supplies 11% of the nation's gas consumption.

- Cooperative ownership structures allow farmers to share investment costs while creating new revenue streams from what was once considered waste material.

- The Danish government's consistent bipartisan support through favourable policies and subsidies has been crucial to the sector's growth.

- Standardised plant designs and economies of scale have driven down costs, making biogas increasingly competitive with traditional energy sources.

- Beyond energy production, biogas cooperatives provide substantial agricultural benefit,s including improved nutrient management and reduced environmental impact of farming.

Denmark's Biogas Revolution: How Farmers Are Powering the Nation

Denmark has quietly engineered one of the world's most successful biogas energy systems. In just over a decade, the country has transformed from having a handful of small-scale biogas facilities to boasting approximately 160 plants that now supply 11% of its national gas consumption. This remarkable achievement stems from a unique combination of cooperative business structures, farmer engagement, and consistent government support that has turned agricultural waste into a valuable energy resource.

At the heart of this transformation is a cooperative model that brings together farmers, energy companies, and local communities. These partnerships have proven particularly effective in Denmark, where there is a strong cultural tradition of cooperative enterprises dating back over a century. BioEnergy Consult, a leading renewable energy advisory firm, highlights Denmark's approach as exemplary for nations seeking to develop sustainable bioenergy systems that benefit both agricultural communities and energy consumers.

What makes the Danish model so compelling is not just its scale but its integration into both agricultural practices and the national energy infrastructure. Unlike many renewable energy projects that exist in isolation from traditional systems, Danish biogas is fully incorporated into the existing natural gas grid, providing a flexible, storable form of renewable energy that complements wind and solar power generation.

The Danish Biogas Model: Farm Waste to Clean Energy

Denmark's biogas revolution represents a perfect marriage between agricultural necessity and renewable energy innovation. The country's intensive livestock production creates significant amounts of manure and slurry – materials that once presented waste management challenges but now serve as the foundation of a thriving energy sector. To understand how this transformation occurs, it's essential to explore what an anaerobic digester is and how it plays a crucial role in converting waste into clean energy.

“Deep Dive Into Danish Biogas | BioCycle” from www.biocycle.net and used with no modifications.

How Agricultural Waste Becomes Renewable Energy

The biogas production process begins at the farm level, where animal manure – primarily from Denmark's substantial pig and cattle operations – forms the base feedstock. This agricultural waste is collected and transported to centralised biogas facilities, where it's combined with other organic materials like food waste, agricultural residues, and dedicated energy crops. Inside large, temperature-controlled digestion tanks, naturally occurring microorganisms break down this organic matter in the absence of oxygen. This anaerobic digestion process releases biogas – a mixture of primarily methane (50-70%) and carbon dioxide (30-50%) – which is captured and then processed further.

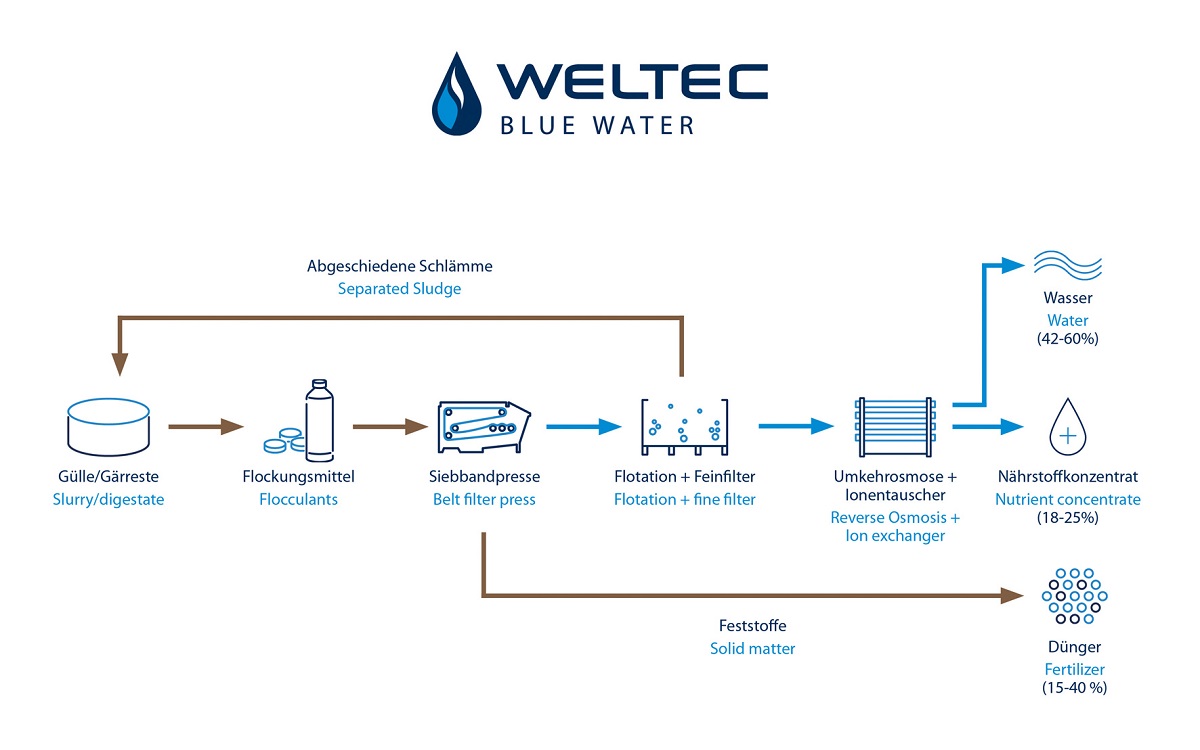

The resulting biogas undergoes purification to remove impurities and increase the methane concentration, creating biomethane that's chemically identical to natural gas. This upgraded gas is then injected directly into Denmark's existing natural gas infrastructure, where it can be distributed to homes, businesses, and industries across the country. Meanwhile, the remaining digestate – the nutrient-rich material left after digestion – is returned to farms as an improved fertiliser, completing a circular economic model.

![]()

“Biogas: Converting Waste to Energy …” from www.eesi.org and used with no modifications.

The Co-operative Ownership Structure

What truly distinguishes the Danish approach is its cooperative ownership model. Rather than single-entity ownership, many Danish biogas plants operate as cooperatives with multiple stakeholders. Farmers typically form the core membership, pooling resources to fund facilities that would be prohibitively expensive for individual operations. This shared investment model distributes both costs and benefits among members, creating economies of scale that improve financial viability. For those interested in the environmental impact, you can explore how anaerobic digestion benefits the environment.

The cooperative structure extends beyond just shared ownership to create integrated supply chains. Member farmers commit to supplying specific volumes of feedstock (primarily manure) to the biogas plant while receiving digestate in return. This arrangement ensures steady input for the biogas facility while providing farmers with improved fertiliser that offers better nutrient availability and reduced odour compared to raw manure. Many cooperatives also include local municipalities, energy companies, and even citizen investors, creating broad community engagement and support.

Government Support That Made It Possible

Denmark's biogas success story would not have been possible without consistent, bipartisan government support spanning decades. The sector's development has been guided by thoughtful policy frameworks that addressed both environmental challenges and energy security concerns. Unlike the boom-and-bust cycles seen in renewable energy development in many countries, Denmark maintained steady support that allowed the industry to mature gradually. For more details on the development of biogas in Denmark, you can explore this comprehensive resource.

- Feed-in tariffs and premiums that guaranteed favourable prices for biogas-generated electricity and biomethane

- Investment grants covering up to 30% of construction costs for new facilities

- Mandates requiring gas grid operators to accept biomethane meeting quality standards

- Tax exemptions for biogas used in heat and power generation

- Research and development funding to improve technologies and reduce costs

This policy consistency created investor confidence that spurred private capital investment. As early as 1995, the Danish Energy Agency formally recognised biogas as an element of the national energy supply in its planning documents. By 2002, government analysis identified biogas as a cost-effective resource for decarbonising the country's energy system, setting the stage for more ambitious development.

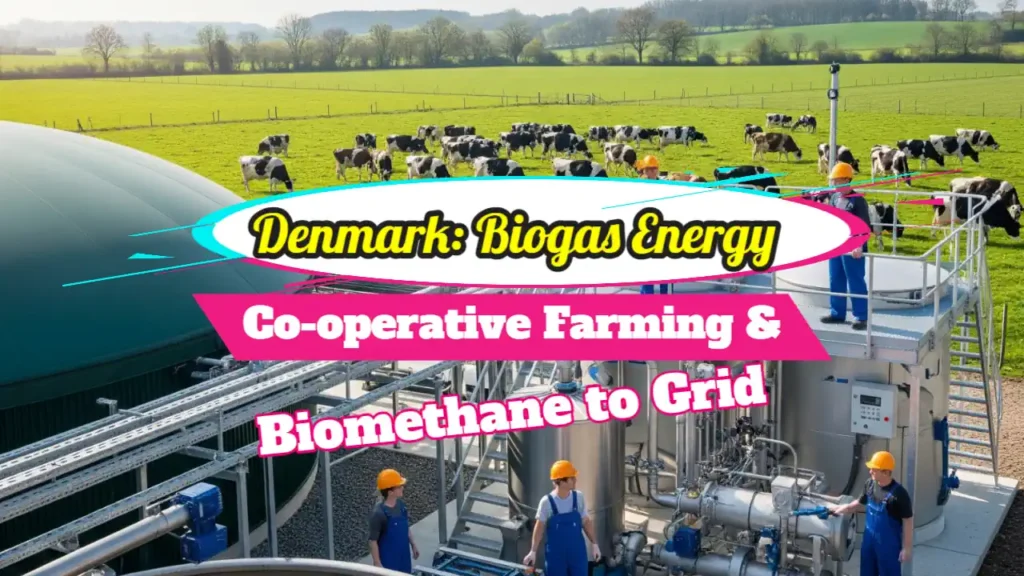

A pivotal moment came with the “Green Growth” political agreement that established an objective of utilising 50% of Denmark's agricultural waste for biogas production. This clear target, backed by supportive policies, accelerated industry growth and attracted larger-scale investment beyond the initial farmer cooperatives.

“Denmark's Green Tax Reform: G20 …” from www.cepweb.org and used with no modifications.

Inside a Danish Biogas Co-operative

The practical operation of Danish biogas cooperatives reveals a sophisticated balance between agricultural expertise and energy production knowledge. These facilities have evolved from small farm-based operations into professional energy enterprises while maintaining their agricultural roots and community connections. For more insights, you can explore a deep dive into Danish biogas practices.

Who Owns the Facilities?

Ownership structures of Danish biogas facilities have diversified as the industry has matured. The earliest plants were typically owned directly by individual farmers or small farmer cooperatives seeking solutions for manure management. Today, ownership models range from traditional farmer cooperatives to hybrid structures involving professional energy companies, municipalities, and institutional investors. Many of the newer and larger facilities represent partnerships between agricultural producers and energy companies like Nature Energy, which brings capital and technical expertise while farmers provide feedstock and land.

A typical mid-sized cooperative might include 15-30 farmer members who collectively own a majority stake in the facility, with additional minority investment from local municipalities or energy utilities. This distributed ownership ensures that value creation remains rooted in the agricultural community while accessing the expertise and capital of energy sector partners. Decision-making typically follows democratic principles, with voting rights proportional to feedstock contribution or capital investment, depending on the specific cooperative's structure. For those interested in the technical aspects of these facilities, understanding what an anaerobic digester is can provide valuable insights.

How Farmers Benefit Financially

The financial benefits for farmer members of biogas cooperatives extend far beyond simple dividend payments. Farmers typically receive multiple revenue streams from their participation, creating a compelling economic case even in challenging agricultural markets. Primary among these benefits is payment for the manure and other biomass materials supplied to the facility. What was once a waste management cost becomes a revenue source, with farmers receiving either direct payment or credits toward their cooperative membership obligations.

Equally important is the return of digestate – the nutrient-rich byproduct of the anaerobic digestion process. This material offers significant advantages over raw manure as a fertiliser, including more plant-available nutrients, reduced odour, and improved consistency for application. Many farmers report fertiliser cost savings of 15-30% after incorporating digestate into their nutrient management practices. Additional benefits include reduced greenhouse gas emissions from manure storage, which can generate carbon credits in some programs, and protection from increasingly strict environmental regulations around manure management.

“Slurry and digestate treatment now …” from gwf-wasser.de and used with no modifications.

Daily Operations and Management

Modern Danish biogas facilities operate as professional energy production plants with sophisticated monitoring systems and dedicated staff. A typical mid-sized cooperative plant processing 200,000-300,000 tons of biomass annually employs 5-10 full-time staff, including plant managers, process engineers, laboratory technicians, and maintenance personnel. Many facilities operate continuously, 24 hours a day, with advanced automation systems monitoring critical parameters like temperature, gas production, and biomass composition.

Feedstock logistics represent a critical operational challenge, with careful scheduling of deliveries to maintain optimal digester performance. Most cooperatives establish detailed delivery schedules for farmer members based on their livestock operations and storage capacity. The largest facilities may receive 30-50 truckloads of biomass daily, requiring sophisticated receiving and pre-treatment systems. Quality control is paramount, with regular laboratory testing of incoming feedstocks and ongoing monitoring of the digestion process to maximise biogas yield and ensure gas quality standards are met. For more insights into biogas production, explore this deep dive on Danish biogas.

Case Study: Nature Energy Månsson Plant

Located in Brande, central Jutland, the Nature Energy Månsson plant exemplifies the evolution of Danish biogas cooperatives toward larger-scale operations with professional management. Opened in 2019, this facility processes approximately 300,000 tons of biomass annually, producing enough biomethane to supply 6,000 households. The plant operates as a partnership between Nature Energy, one of Denmark's leading biogas developers, and a cooperative of 17 local farmers who supply most of the facility's feedstock.

What distinguishes this facility is its integrated approach to agricultural waste management and energy production. Beyond standard manure processing, the plant incorporates sophisticated pre-treatment technologies that allow it to process challenging materials like deep litter from poultry operations and straw-rich cattle bedding. These innovations have increased biogas yields by approximately 15% compared to earlier generation plants.

Biomethane to Grid: The Technical Process

From Raw Biogas to Grid-Quality Biomethane

The transformation of raw biogas into grid-quality biomethane involves several sophisticated technical processes designed to achieve natural gas quality standards. Raw biogas from the digestion tanks typically contains 50-70% methane, 30-50% carbon dioxide, and trace amounts of hydrogen sulfide, ammonia, and water vapour – all of which must be addressed before grid injection. The purification process begins with basic cleaning to remove particulates and reduce hydrogen sulfide levels, often using biological desulfurization methods that are both cost-effective and environmentally friendly.

The critical step is upgrading – separating methane from carbon dioxide to increase energy content. Danish facilities predominantly use water scrubbing or membrane separation technologies, with the latter gaining popularity for its energy efficiency and scalability. These upgrading systems typically achieve 98-99% methane purity, meeting or exceeding the Danish standard of 97% methane content for grid injection. The captured CO₂ isn't wasted – many newer facilities are incorporating carbon capture systems that purify this CO₂ for use in industrial applications or greenhouse cultivation, further improving the environmental profile and economics of biogas production.

Infrastructure Requirements

Denmark's success in integrating biomethane into its energy system stems from strategic infrastructure investments that connected biogas facilities to the existing natural gas grid. Most Danish biogas plants are purposefully located within reasonable proximity to gas grid connection points, typically requiring less than 10 kilometres of dedicated pipeline. The infrastructure includes not just connecting pipelines but also compression stations that increase gas pressure to match grid requirements, quality monitoring equipment that continuously analyses gas composition, and injection stations where the biomethane enters the main distribution network. For a deeper understanding, you can explore more about Danish biogas.

The Danish gas grid operator, Energinet, has played a pivotal role by establishing clear technical standards for biomethane and creating streamlined connection processes. Importantly, Denmark implemented a “right to inject” policy that requires grid operators to accept biomethane meeting quality standards, removing a potential barrier to market access. The costs of grid connection are typically shared between the biogas producer and the grid operator according to established formulas, creating transparency and predictability for project developers. This infrastructure-focused approach has allowed Denmark to achieve biomethane injection rates that lead Europe, with minimal disruption to existing gas supply chains. For more information on biogas systems, you can explore biogas grit removal systems.

Storage Solutions in the Existing Gas Network

One of biomethane's greatest advantages is its compatibility with existing natural gas infrastructure, allowing seasonal storage that addresses the intermittency challenges common to many renewable energy sources. Denmark leverages its gas network as an enormous energy storage system, with biogas production remaining relatively constant year-round while consumption follows seasonal patterns with winter heating demand peaks. During summer months when gas demand is lower, the biomethane production essentially charges this national-scale “battery,” which is then discharged during winter when energy demand increases – a perfect complement to wind power, which typically has higher production in winter months.

Real-World Results: Denmark's Biogas Success Story

The Danish biogas sector has evolved from a niche agricultural waste management solution into a cornerstone of the country's renewable energy strategy. This transformation represents one of the most successful integrations of agricultural and energy systems globally, delivering multiple environmental and economic benefits while advancing Denmark's ambitious climate goals. The sector's growth has accelerated dramatically in recent years, transforming from approximately 50 operating plants in 2012 to approximately 160 facilities in 2023, with production continuing to expand.

11% of National Gas Consumption (and Growing)

Denmark has achieved what many energy experts once considered impossible – replacing a significant portion of its fossil natural gas consumption with renewable biomethane from agricultural waste. As of 2023, biogas-derived biomethane accounts for approximately 11% of Denmark's total gas consumption, up from just 3% in 2015. This remarkable growth trajectory continues, with projections suggesting biomethane could supply 30-40% of Denmark's gas needs by 2030 as production expands and overall gas consumption decreases through electrification and efficiency improvements. The majority of this production comes from approximately 50 large-scale plants that inject directly into the gas grid, with the remainder used for local combined heat and power generation at smaller facilities. For more information on biogas in Denmark, visit the Energistyrelsen website.

Carbon Reduction Achievements

The climate impact of Denmark's biogas sector extends far beyond simply replacing fossil fuels with renewable alternatives. By capturing methane emissions that would otherwise be released from conventional manure storage and management, biogas production delivers a double climate benefit. The Danish Energy Agency estimates that each cubic meter of biomethane produced provides greenhouse gas reductions equivalent to 2-3 cubic meters of natural gas when accounting for these avoided agricultural emissions. In 2022 alone, Danish biogas production reduced national greenhouse gas emissions by approximately 1.7 million tonnes of CO₂ equivalent, representing nearly 3% of the country's total emissions and a significant contribution to Denmark's goal of 70% emissions reduction by 2030.

Agricultural Benefits Beyond Energy

- Improved nutrient management with digestate provides more precise fertilisation capabilities than raw manure

- Significant odour reduction in both storage and field application of processed manure

- Reduction in weed seeds and pathogens through the anaerobic digestion process

- Decreased chemical fertiliser requirements, reducing both costs and environmental impacts

- Creation of new revenue streams for farmers facing challenging agricultural economics

Beyond these direct benefits, the biogas sector has created approximately 2,500 full-time jobs in rural Denmark, primarily in areas facing population decline and economic challenges. The industry has spawned a robust supply chain of technology providers, consultants, and service companies that now export Danish biogas expertise globally. This rural economic development aspect has been particularly important in maintaining political support for the sector across changing governments and economic conditions.

The environmental benefits extend to water quality protection as well. The improved nutrient management capabilities of digestate versus raw manure have helped farmers comply with increasingly strict regulations regarding nitrogen and phosphorus application. Studies show reduced nutrient runoff from fields fertilised with digestate compared to those using raw manure, contributing to Denmark's efforts to protect coastal waters and comply with the EU Water Framework Directive requirements.

Perhaps most remarkably, the biogas sector has transformed perceptions of agricultural waste. What was once viewed primarily as an environmental liability is now recognised as a valuable renewable resource. This conceptual shift has implications beyond energy production, contributing to broader circular economy thinking throughout the agricultural sector and inspiring innovations in resource recovery and utilisation.

The Economics of Danish Biogas Co-operatives

The financial underpinnings of Denmark's biogas success story reflect a careful balance between public support mechanisms and private investment. Unlike many renewable energy technologies that rely primarily on one revenue stream, biogas cooperatives typically develop multiple value propositions spanning energy production, waste management services, and agricultural benefits. This diversified approach has proven more resilient to policy changes and market fluctuations than single-purpose renewable energy installations.

The Economics of Danish Biogas Co-operatives

The financial underpinnings of Denmark's biogas success story reflect a careful balance between public support mechanisms and private investment. Unlike many renewable energy technologies that rely primarily on one revenue stream, biogas cooperatives typically develop multiple value propositions spanning energy production, waste management services, and agricultural benefits. This diversified approach has proven more resilient to policy changes and market fluctuations than single-purpose renewable energy installations.

Initial Investment Costs

Establishing a modern, grid-connected biogas facility in Denmark represents a significant capital investment. For a typical cooperative plant processing 300,000 tons of biomass annually, total investment costs range from €15-25 million (approximately $16-27 million), depending on location, feedstock types, and upgrading technology choices. These costs encompass the anaerobic digestion system, gas upgrading equipment, grid connection infrastructure, biomass receiving and pre-treatment facilities, and digestate handling systems. The capital intensity of biogas facilities historically presented a barrier to widespread adoption, particularly for farmer-led initiatives with limited access to financing.

Denmark addressed this challenge through targeted investment support programs that reduced upfront capital requirements. During the sector's early growth phase, government grants covered up to 30% of eligible investment costs for qualifying projects. As the industry matured and technologies standardised, these direct subsidies have gradually reduced, replaced by more market-based support mechanisms. Many newer projects now utilise public-private partnership models that bring together agricultural cooperatives with institutional investors and energy companies, creating more sophisticated financing structures that distribute risk and leverage each partner's expertise.

Revenue Streams for Co-operative Members

The economic sustainability of Danish biogas cooperatives stems from their ability to generate multiple revenue streams across the energy, agricultural, and environmental sectors. Primary among these is energy sales, with most facilities receiving both the market value of the biomethane produced and additional premiums for its renewable attributes. The Danish support system has evolved from fixed feed-in tariffs to a more flexible premium model that adjusts based on natural gas prices, providing price stability while maintaining market connection. These energy payments typically account for 60-75% of a facility's total revenue.

Beyond energy sales, many cooperatives generate significant income from gate fees for processing organic wastes from food processing, municipalities, and industries. These materials not only provide tipping fee revenue but also often boost biogas yields due to their high energy content. Farmers benefit from reduced fertiliser costs through digestate utilisation, with many reporting 15-30% savings on their fertiliser budgets. Some cooperatives have developed additional revenue streams through carbon credit generation, heat recovery systems, and specialised organic fertiliser products created from processed digestate. This diversity of income sources has proven crucial to maintaining economic viability through fluctuating energy markets and policy environments.

Payback Periods and Long-term Profitability

The economic performance of Danish biogas cooperatives has improved substantially as the sector has matured, with greater operational efficiency and economies of scale driving better returns. Early facilities often struggled with 12-15 year payback periods that challenged financial viability, but modern plants utilising current technology and operating at optimal scale typically achieve payback within 7-10 years. This improvement reflects both technological advances and accumulated operational expertise that has reduced both capital and operating costs while increasing biogas yields.

Long-term profitability depends heavily on operational excellence, particularly in feedstock management and process optimisation. The most successful cooperatives maintain detailed monitoring of all biological processes, optimise feedstock mixtures to maximise methane yields, and implement preventative maintenance programs that minimise downtime. Many facilities report internal rates of return between 8-12% after the initial payback period, creating sustainable business models that continue to attract investment. Perhaps most importantly, the integrated nature of these cooperatives distributes benefits across multiple stakeholders – from farmers receiving improved fertiliser and waste management solutions to energy consumers accessing renewable gas, and local communities benefiting from reduced environmental impacts and economic development.

Challenges and Solutions in the Danish Model

Despite its impressive achievements, Denmark's biogas sector has navigated significant challenges throughout its development. Understanding these obstacles and the solutions that emerged provides valuable insights for other regions seeking to replicate this success. Rather than undermining the model, these challenges have ultimately strengthened the sector by driving innovation, improving operational practices, and building broader stakeholder support.

Odour Management Strategies

Odour concerns presented one of the earliest and most persistent challenges to biogas facility development, particularly for plants located near residential areas. Early facilities sometimes faced community opposition due to both real and perceived odour impacts from transportation, storage, and processing of manure and other organic materials. The industry responded with comprehensive odour management strategies that have largely resolved these issues and established biogas plants as good neighbours within their communities.

Modern Danish facilities incorporate multiple odour control systems, beginning with enclosed receiving areas that operate under negative pressure to prevent fugitive emissions. All high-odour processes occur within buildings equipped with advanced biofilter systems that remove 95-99% of odorous compounds before air is released. Transportation logistics have been optimised with sealed tanker trucks, scheduled deliveries to avoid peak community activity times, and designated route planning to minimise residential exposure. Perhaps most importantly, the anaerobic digestion process itself significantly reduces odour compounds in the digestate compared to raw manure, creating an overall net reduction in agricultural odour impacts when the full system is considered.

“Carbon filtration helps Middelfart …” from www.camfil.com and used with no modifications.

Digestate Utilisation Innovations

Managing the digestate output from biogas production initially presented logistical and agronomic challenges. The liquid digestate, while valuable as fertiliser, required substantial storage capacity and had seasonal application limitations. Danish farmers and biogas operators have developed innovative approaches to maximise digestate value while addressing these constraints, transforming what could have been a limitation into an additional benefit stream. For more insights, explore how dairy digesters boost farm income through biogas plant integration.

Advanced nutrient recovery systems now separate digestate into liquid and solid fractions, allowing more precise application based on crop needs. The phosphorus-rich solid fraction can be transported longer distances economically, enabling better nutrient distribution beyond the immediate vicinity of the biogas plant.

Several cooperatives have invested in digestate processing facilities that create specialised organic fertiliser products tailored to specific crops and growing conditions, commanding premium prices in organic farming markets. Perhaps most innovative are the closed-loop systems where digestate nutrients support greenhouse production of vegetables or algae cultivation, creating additional high-value products while recycling nutrients in a controlled environment.

Scaling to Meet National Goals

As Denmark's climate ambitions have expanded, the biogas sector faces the challenge of scaling production substantially while maintaining its agricultural integration and environmental benefits. The most accessible agricultural feedstocks are already largely utilised in existing plants, requiring new approaches to sustain growth. The industry is responding through several parallel strategies that promise to maintain momentum while preserving the core benefits of the Danish model.

Technological innovations are expanding the range of viable feedstocks, with advanced pre-treatment systems now enabling efficient digestion of straw, deep litter, and other previously challenging agricultural residues. Several facilities are pioneering sustainable energy crop integration, using cover crops and perennial grasses grown on marginal lands to supplement manure-based feedstocks without competing with food production. Industry consolidation is creating larger, more efficient plants that can justify sophisticated gas processing and by-product recovery systems.

Perhaps most significant is the emerging integration with other renewable energy systems, particularly using excess wind energy for power-to-gas applications that can increase biomethane output through biological methanation processes – effectively storing wind energy in the gas grid and demonstrating how biogas can help solve intermittency challenges in high-renewable energy systems.

From Denmark to the World: Adapting Their Success

Denmark's biogas cooperative model offers valuable lessons for countries worldwide seeking to develop sustainable bioenergy systems that benefit both agricultural communities and energy consumers. The Danish experience demonstrates that with appropriate policy frameworks, technological expertise, and stakeholder engagement, agricultural biogas can scale from niche applications to significant contributions within national energy systems. In 2018, the Danish Trade Council, INBIOM/Agro Business Park, and the Danish Energy Agency formed “Biogas Go Global,” a partnership specifically aimed at sharing Danish biogas expertise internationally, particularly targeting the United States market, where agricultural scale and waste volumes offer enormous potential.

The transferability of the Danish model depends on adapting core principles to local agricultural systems, energy markets, and policy environments rather than direct replication. The cooperative ownership structure can be modified to accommodate different legal frameworks while maintaining the essential principle of distributed benefits among agricultural producers. The technical systems developed in Denmark for feedstock handling, digestion optimisation, and gas upgrading can be adapted to different climates and agricultural waste streams. Perhaps most importantly, the policy approach of stable, long-term support frameworks with a clear connection to both environmental and energy objectives can be implemented in various regulatory contexts. Success stories are already emerging in countries like France, Italy, and parts of North America, where adaptations of the Danish cooperative model are enabling agricultural communities to participate in renewable energy production while addressing waste management challenges.

Frequently Asked Questions

As interest in biogas cooperatives grows internationally, many stakeholders seek specific information about Denmark's experience. The following questions address the most common inquiries from farmers, policymakers, and renewable energy developers exploring similar models in their regions.

These insights from Denmark's pioneering work can help guide development while recognising that each implementation will require adaptation to local conditions and opportunities.

How much of Denmark's gas supply comes from biogas?

As of 2023, biogas-derived biomethane accounts for approximately 11% of Denmark's total gas consumption, up from just 3% in 2015. This percentage continues to grow rapidly, with projections suggesting biomethane could supply 30-40% of Denmark's gas needs by 2030. This growth reflects both increasing production capacity and declining overall gas consumption as Denmark shifts toward electrification in many sectors. During certain periods of low demand (typically summer months), biomethane has briefly supplied over 30% of the gas in parts of the Danish distribution network, demonstrating the potential for very high renewable gas penetration rates.

Do Danish farmers make money from biogas co-operatives?

Yes, Danish farmers typically realise multiple revenue streams from biogas cooperative participation. Most directly, they receive payment for the manure and other biomass materials supplied to the facility – converting what was previously a waste management cost into income. As cooperative members, they also receive dividends from the facility's energy sales and waste processing operations. Equally significant are the agricultural benefits, including receiving digestate that reduces fertiliser costs by 15-30% for most operations while improving nutrient utilisation efficiency. Many farmers report that these combined benefits improve their overall farm profitability by 5-10%, providing important diversification in an industry with traditionally narrow profit margins. For more on how biogas compares with other renewable energy options, see biogas vs. solar vs. wind for farms.

What feedstocks do Danish biogas plants use?

Danish biogas plants utilise a diverse mix of organic materials, with animal manure forming the foundation at 60-70% of total volume. Cattle and pig slurry dominate, supplemented by deep litter from poultry and cattle bedding. Industrial food processing wastes contribute 10-15%, including residues from slaughterhouses, dairies, breweries, and vegetable processing. Municipal organic waste collections provide approximately 5-10% of feedstock volume, while dedicated energy crops like maize and sugar beets have declined to less than 5% as sustainability concerns have shifted focus toward waste materials. An emerging feedstock category is agricultural residues like straw and cover crops, which currently contribute 5-10% but are expected to increase as pre-treatment technologies improve, offering significant growth potential without competing with food production.

How long does it take to build a biogas co-operative?

The development timeline for a Danish biogas cooperative typically spans 2-4 years from initial concept to operational facility. The process begins with a feasibility assessment and formation of the cooperative structure, generally requiring 6-9 months to analyse feedstock availability, secure member commitments, and develop preliminary business plans. Permitting and regulatory approval represent the most variable timeframe, typically requiring 9-18 months depending on location, scale, and local conditions. The actual construction phase usually takes 12-15 months for a mid-sized facility, followed by a 3-6 month commissioning period during which operations are gradually scaled up to full capacity. Projects led by established developers with previous biogas experience typically progress more quickly, while first-time cooperatives often require additional time for member education and organisational development.

Is the Danish biogas model transferable to other countries?

The core principles of the Danish biogas cooperative model are transferable internationally, though successful implementation requires adaptation to local agricultural systems, energy markets, and regulatory frameworks. The collaborative structure bringing together multiple farmers to achieve economic scale is applicable in most agricultural regions, though specific ownership models may need modification to accommodate different legal traditions. For more insights on how biogas can benefit farms, explore biogas vs solar vs wind for farms.