In the evolving landscape of sustainable agriculture and waste management, digestate drying emerges as a promising solution. Digestate, the byproduct of anaerobic digestion processes, offers significant potential as a renewable fertilizer. However, the process of drying digestate demands considerable energy, primarily in the form of heat.

This raises a critical question:

Is digestate drying environmentally and economically justifiable?

The answer can be an emphatic; Yes! The main reason for drying digestate is that as it leaves the digester tank it is at least 90% water. Therefore, the fertiliser product, once dried is hugely cheaper to transport making it far more valuable. In addition there are high value applications for it once it has ben dried such as its use as a bedding material for livestock.

This comprehensive analysis delves into the environmental benefits and economic considerations of digestate drying, presenting a balanced view to help stakeholders make informed decisions.

Understanding Digestate and the Drying Process

What is Digestate?

Digestate is the residual material left after the anaerobic digestion of organic matter, such as agricultural waste, manure, and food scraps. It comprises both a solid fraction and a liquid fraction, rich in nutrients like nitrogen, phosphorus, and potassium, making it an excellent candidate for fertilizer application.

The Drying Process Explained

Drying digestate involves reducing its moisture content to create a more stable, concentrated fertilizer product. This process typically requires significant heat, which can be sourced from various energy types, including heat from the anaerobic digestion plant that produced the digestate, but also other renewable and non-renewable sources. The primary methods of drying include:

- Mechanical Drying: Utilizing equipment like rotary dryers or belt dryers to remove moisture.

- Thermal Drying: Applying heat through combustion or electrical means to evaporate water content.

- Solar Drying: Leveraging solar energy to naturally reduce moisture levels, though this method is less controlled and dependent on weather conditions.

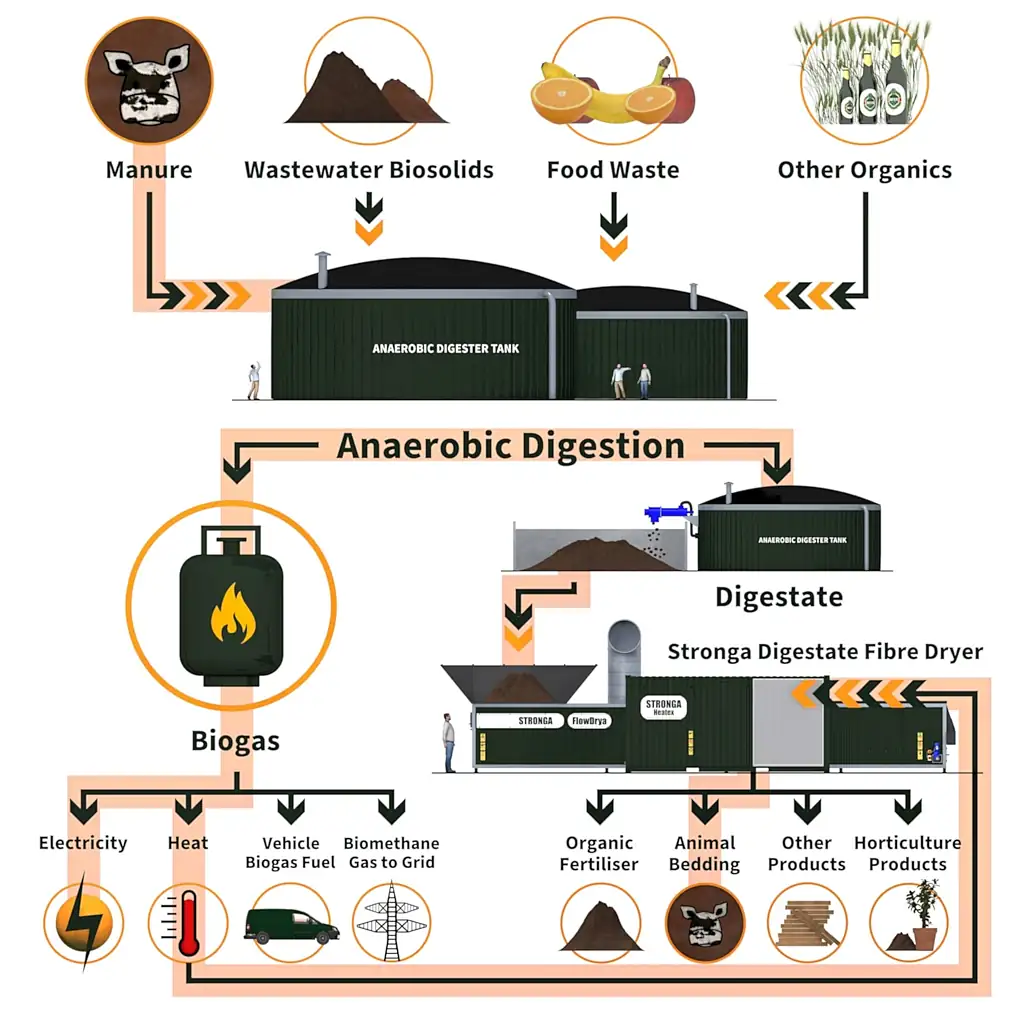

“Drying Digestate Fibre for Animal Bedding…” from stronga.com and used with no modifications.

Environmental Implications

Benefits of Digestate Drying

- Enhanced Nutrient Management: Drying concentrates nutrients, making it easier to transport and apply as fertilizer with precision, reducing nutrient runoff and environmental pollution.

- Waste Reduction: Converts organic waste into valuable products, minimizing the environmental footprint of waste disposal.

- Renewable Fertilizer Production: Promotes circular economy practices by turning waste into agricultural inputs, reducing dependency on synthetic fertilizers derived from finite resources.

Disadvantages of Digestate Drying

When digestate is dried along with the water that is emitted s humid air there will be a substantial emission of ammonia gas. This can be collected in wet scrubbing towers and becomes a useful basis for additional fertiliser production.

Unfortunately, we have seen a number of examples that don't appear to collect the ammonia gas, with that meaning that the local ecology will be likely to impacted.

Energy Consumption and Carbon Footprint

While the environmental benefits are substantial, the drying process itself is energy-intensive. The source of this energy plays a pivotal role in determining the overall environmental impact:

- Renewable Energy Sources: Utilizing biomass, solar, or wind energy can mitigate the carbon footprint associated with drying, enhancing the sustainability of the process.

- Non-Renewable Energy Sources: Dependence on fossil fuels for heat increases greenhouse gas emissions, potentially offsetting the environmental gains from using digestate as fertilizer.

Life Cycle Assessment (LCA)

A comprehensive LCA assesses the environmental impacts from cradle to grave. Studies indicate that when digestate drying is powered by renewable energy, the overall environmental benefits surpass the energy inputs. However, if non-renewable energy dominates, the benefits can be significantly reduced, necessitating careful energy sourcing.

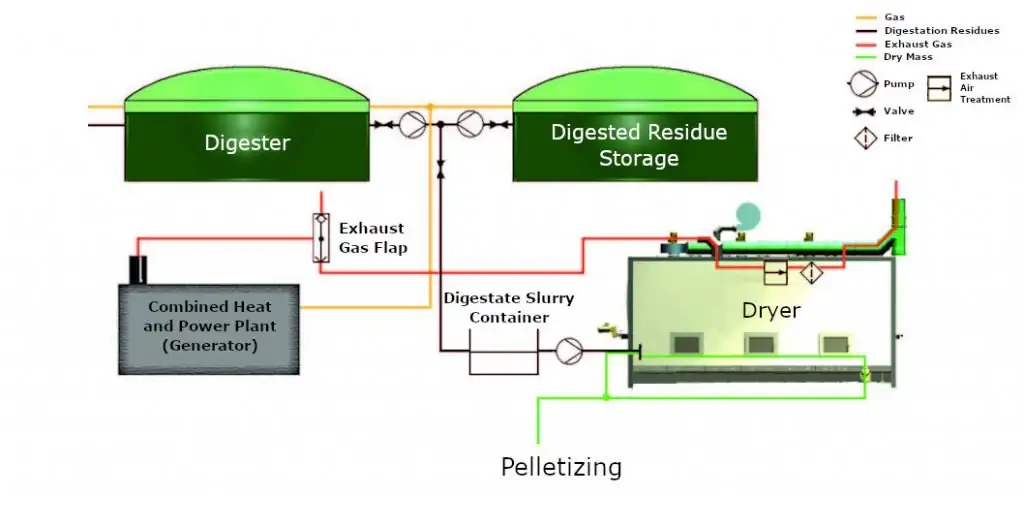

“Digestate Drying – Universal Drying Systems” from www.universaldryingsystems.com and used with no modifications.

Mechanical separation of digestate to 35% dry matter would allow operators to assign 25% of supply chain emissions to the digestate using the Renewable Energy Directive LCA approach. Thermal treatment (drying) of digestate to 90% dry matter improves the allocation to 38%, allowing feedstocks that would otherwise be judged unsustainable to meet the GHG requirements. (Source: NNFCC, “Assessment of digestate drying as an eligible heat use in the Renewable Heat Incentive”; Project Number: 16-015.5; March 2016. A report for DECC Heat Team.)

Economic Considerations

Cost Analysis

The economics of digestate drying encompass several factors:

- Capital Investment: High initial costs for drying equipment and infrastructure can be a barrier for many operations.

- Operational Costs: Ongoing expenses include energy consumption, maintenance, and labor.

- Revenue Streams: Dried digestate can be sold at a premium compared to liquid forms, offsetting some of the costs. Additionally, there may be savings from reduced waste disposal fees and potential incentives for sustainable practices.

Return on Investment (ROI)

The ROI for digestate drying projects varies based on:

- Scale of Operation: Larger facilities benefit from economies of scale, reducing the per-unit cost of drying.

- Energy Efficiency: Advanced drying technologies that optimize energy use can enhance profitability.

- Market Demand: Strong demand for organic fertilizers and premium pricing can improve financial viability.

Funding and Incentives

Governments and environmental bodies often provide grants, subsidies, or tax incentives to promote sustainable practices like digestate drying. Securing such funding can significantly improve the economic outlook of drying projects.

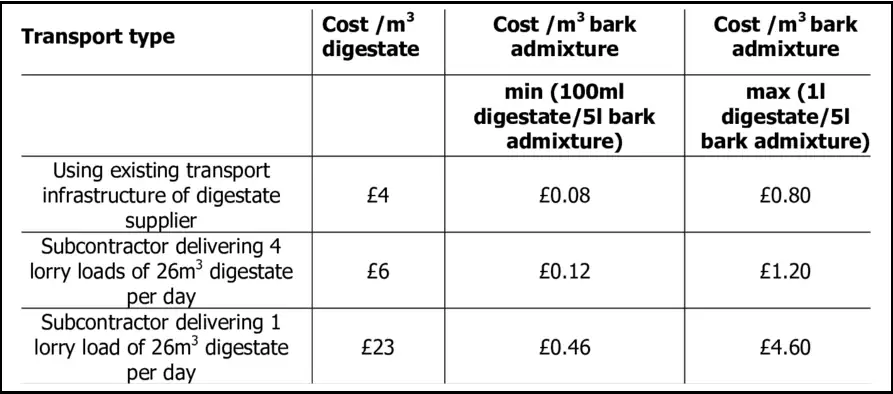

“variability of transport cost of whole or liquid digestate…” from www.researchgate.net and used with no modifications.

Technological Innovations

Advancements in drying technologies are pivotal in enhancing both the environmental and economic feasibility of digestate drying:

- Energy-Efficient Dryers: Development of dryers that require less energy while maintaining high drying efficiency can reduce operational costs and emissions.

- Integrated Systems: Combining anaerobic digestion with drying processes allows for energy recovery and optimized resource use.

- Smart Controls: Implementing IoT and automation for precise temperature and moisture control improves efficiency and reduces waste.

Future Trends

The future of digestate drying lies in innovation and integration. Emerging trends include:

- Biomass Integration: Utilizing the biogas produced from anaerobic digestion to power the drying process, creating a self-sustaining loop.

- Modular Drying Units: Scalable drying systems that can be easily adjusted based on production needs and energy availability.

- Advanced Materials: Use of materials with better thermal properties to enhance drying efficiency.

Comparative Analysis: Dry vs. Liquid Digestate

Understanding the differences between dried and liquid digestate is crucial for assessing the benefits of drying:

Transport and Storage

- Dried Digestate: Lighter and more compact, reducing transportation costs and storage space requirements.

- Liquid Digestate: Requires more space and higher transportation costs due to the higher moisture content.

Application Flexibility

- Dried Digestate: Can be easily applied using standard fertilizer equipment, allowing for more precise nutrient management.

- Liquid Digestate: Limited by the need for specialized application equipment and can lead to uneven nutrient distribution.

Marketability

- Dried Digestate: Higher market value as an organic fertilizer, appealing to environmentally conscious consumers and organic farmers.

- Liquid Digestate: Generally lower market value, often used primarily as a soil conditioner.

How to Sell Digestate as a Natural Fertilizer

To sell digestate as a Natural Fertilizer in the UK it has to comply with the WRAP PAS 110 specification.

Digestate must fulfil the criteria outlined in the Quality Protocol and BSI PAS110 specification (England & Wales) or the SEPA position statement in order to be sold as a natural biofertiliser (Scotland).

PAS110 defines minimum quality criteria for source-segregated biowaste whole digestate, separated fibre, and separated liquor. There is no necessity, however, for items to be specially dried or dewatered.

For bigger operators (commercial and industrial locations), digestate disposal is generally a cost to the business. But drying digestate to create a crystalized fertiliser can add significant value and make it economically viable.

Where digestate is sold offsite, WRAP surveys showed an average in 2016 price of approximately £3.73 per tonne, with similar studies ranging up to £5 per tonne, although data on this is scarce and often not published for being commercially sensitive.

Challenges and Mitigation Strategies

High Energy Demand

Challenge: The significant energy required for drying can undermine the environmental and economic benefits.

Mitigation Strategies:

- Renewable Energy Integration: Shift to renewable energy sources to power drying processes.

- Energy Recovery Systems: Implement systems that capture and reuse waste heat from other processes.

- Process Optimization: Enhance drying efficiency through advanced control systems and optimized process parameters.

Capital Investment Barriers

Challenge: The high upfront costs can deter investment in digestate drying facilities.

Mitigation Strategies:

- Financing Solutions: Explore loans, grants, and partnerships to spread capital costs.

- Incremental Implementation: Gradually scale up drying capacity to manage investment risks.

- Public-Private Partnerships: Collaborate with governmental and private entities to share investment burdens and benefits.

Market Fluctuations

Challenge: Variability in fertilizer prices and demand can affect the profitability of drying operations.

Mitigation Strategies:

- Diversified Revenue Streams: Explore multiple markets, such as biomass energy production or soil amendment products.

- Long-Term Contracts: Secure stable pricing through long-term supply agreements with agricultural producers.

- Value-Added Products: Develop premium products with higher nutrient concentrations or specialized formulations to attract niche markets.

Case Studies: Successful Digestate Drying Implementations

Case Study 1: A Green Farm Solution

A green farming business implemented a state-of-the-art digestate drying facility powered entirely by biogas generated on-site. This integration not only reduced their carbon footprint but also lowered operational costs by utilizing waste heat, demonstrating the viability of renewable energy in digestate drying. It also reduced their cost of chemical fertilizer.

“Drying Digestate Fibre for Animal …” from stronga.com and used with no modifications.

Case Study 2: Liquid Fertilizer Plus Heat Recovery

A company invested in advanced energy-efficient dryers and secured government subsidies for sustainable practices. The digester output contained contaminants from municipal waste processing that meant that dry digestate land application was banned due to metals and small plastic present. The combination of technological innovation and financial support enabled them to achieve a profitable and environmentally responsible operation, setting a benchmark in the industry.

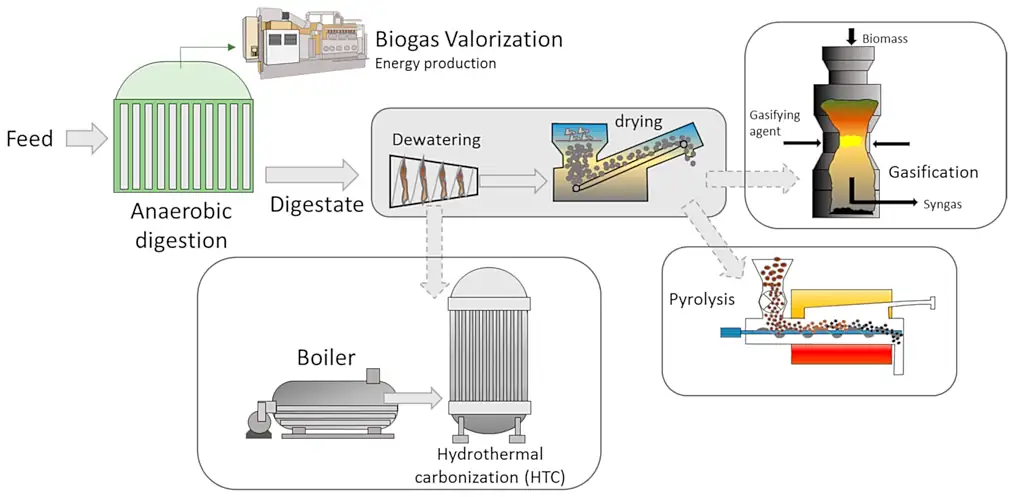

“Digestate Thermal Valorization …” from www.mdpi.com and used with no modifications.

Conclusion: Weighing the Environmental and Economic Factors

Digestate drying stands at the intersection of sustainability and economic viability. When powered by renewable energy sources and supported by technological advancements, it offers substantial environmental benefits, including enhanced nutrient management, waste reduction, and the production of renewable fertilizers.

The cost of transporting the resulting fertilizer alone is reduced by the up to 10 fold reduction in weight.

Economically, while the initial investment and operational costs are significant, the potential for premium product pricing, cost savings, and revenue diversification presents a compelling case for its adoption.

However, the justification for digestate drying hinges on careful planning and strategic implementation. Stakeholders must consider energy sourcing, technological choices, and market dynamics to optimize both environmental and economic outcomes. By addressing the inherent challenges and leveraging available incentives and innovations, digestate drying can indeed make sense both environmentally and economically, contributing to a more sustainable and prosperous future.

Ready to Optimize Your Digestate Drying Process?

Contact us today to learn how advanced drying solutions can enhance the sustainability and profitability of your operations. Get in Touch | Request a Consultation

Frequently Asked Questions

- What is the primary benefit of drying digestate?

- – Drying digestate concentrates nutrients, making it easier to transport and apply as a high-quality organic fertilizer.

- Can digestate drying reduce greenhouse gas emissions?

- – Yes, especially when the drying process utilizes renewable energy sources, significantly lowering the overall carbon footprint.

- What are the main economic challenges of digestate drying?

- – High initial capital investment and ongoing operational costs are the primary economic challenges, which can be mitigated through financing, subsidies, and technological efficiencies.

- Is dried digestate suitable for all types of crops?

- – Dried digestate is versatile and can be used across various crops, offering precise nutrient management to meet different agricultural needs.

Learn More About Our Services

Explore our range of sustainable waste management and fertilizer solutions designed to meet your agricultural and environmental goals. Explore Services

{Article first published 18 September 2021. Extensively re-written in March 2025.]

Chemical fertiliser isn’t everything that’s wrong with the global agriculture economy. That doesn’t mean the issue isn’t serious; rather, it’s only a symptom of a much bigger problem. I’d want to see more people/channels take a deeper look at these subjects.