Egg Shaped Anaerobic Digesters; Enormous eggs! Whatever next! Have you ever wondered what those huge “strangely other-world like” not quite “spherical” tanks are that you sometimes see?

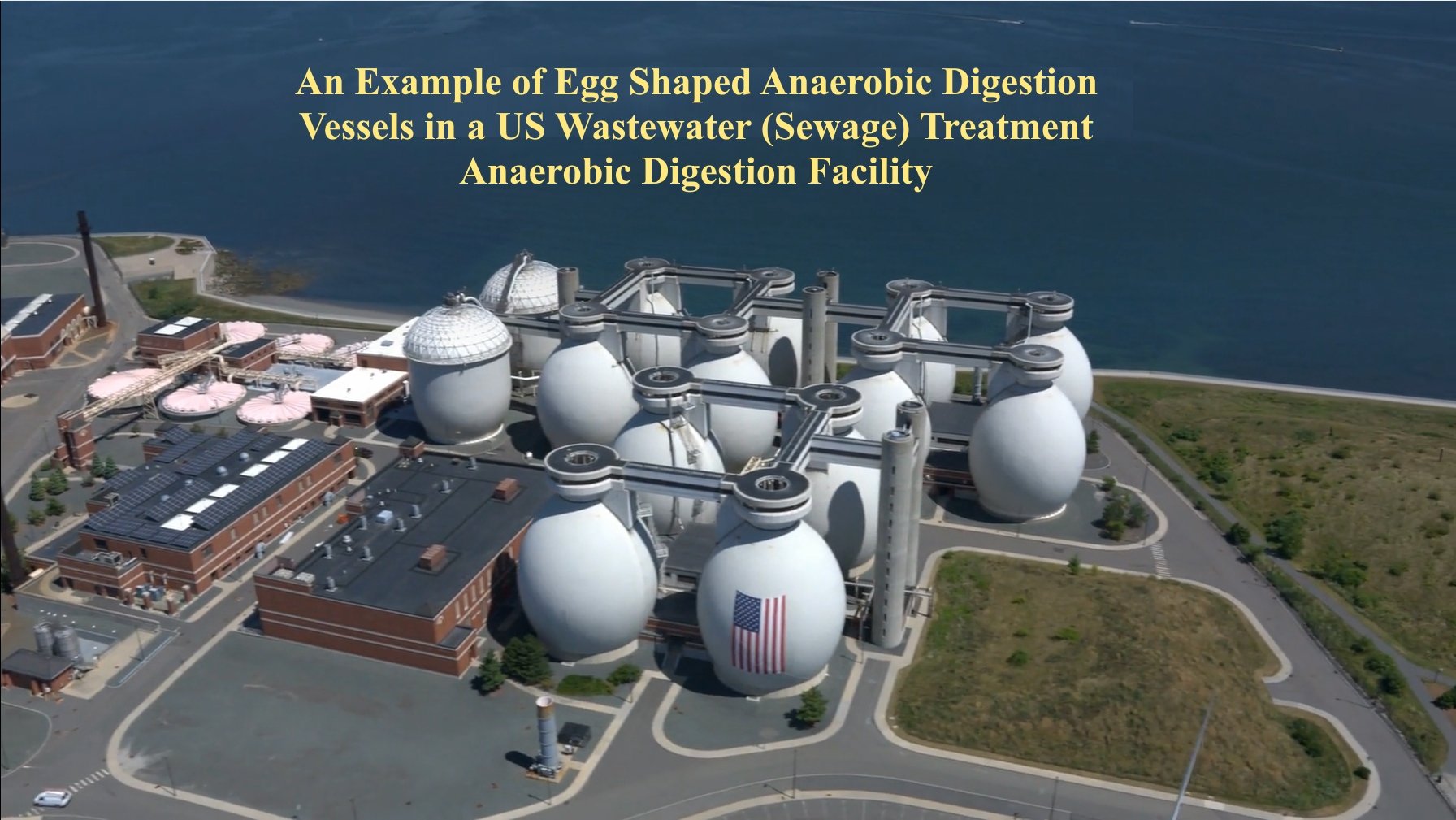

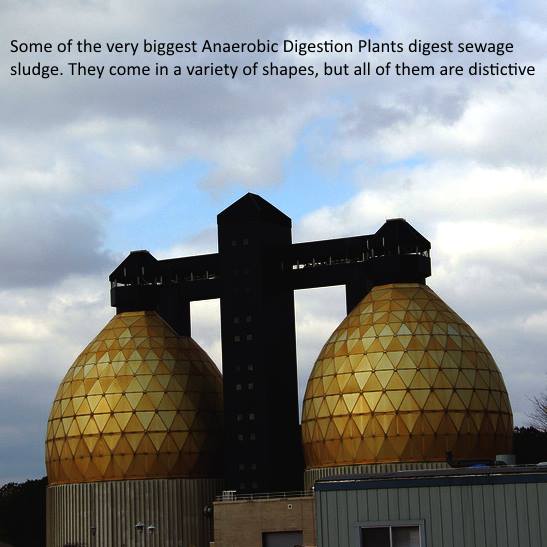

An example image of a US biosolids biogas digester at a sewage works.

An example image of a US biosolids biogas digester at a sewage works.

They are anaerobic digestion process digesters, and very useful they are too!

Egg-shaped anaerobic digesters (ESDs) are a type of digester, often used for wastewater sludge treatment, that uses their unique double-curved shape for enhanced mixing and process efficiency.

This design minimizes issues like scum and dead zones, and the shape itself helps to reduce maintenance needs and increase reliability. They have been used for decades and have evolved in design to overcome challenges like foaming in the narrower upper section.

They make sewage sludge much more wholesome and, in particular, they reduce sludge odour, but best of all, they make large amounts of renewable energy to power the sewage works they form part of.

If you found our video interesting, now read more about sewage sludge on our main website.

This video was inspired by the presentation on egg-shaped digesters at: mebig.marmara.edu

Egg-Shaped Anaerobic Digesters – Very “Quatermass”!

Plus, many of them export their “green” electricity to the local power grid. The egg shape looks really quite strange, but it provides for good mixing.

Quantitative studies of two mixing techniques and two digester forms revealed that mechanical draught tube mixing is more efficient than external pumped recirculation, and the egg shape is more efficient than the cylindrical design. The best main pumping mode and the optimal position of the mixer propeller attached inside the tube were determined through testing.

Origins of the Egg-Shaped Digester

Egg-shaped digesters originated in Germany in the 1950s, and it is thought that all are used to treat sewage works sludge.

Egg-Like Digester Design is Optimum

Design features are many, as follows:

- The steeply sloped bottom of the tank eliminates grit accumulation. Grit can easily be removed from the bottom; therefore, cleaning is not required.

- The liquid surface area at the top is small, so scum can be kept fluid with a mixer and removed through a scum door.

- Egg-shaped digesters can be built with steel or concrete.

- Steel construction is more common because concrete construction requires complex formwork and special construction techniques.

- The shape is such that the vessel does not need to be removed from service for cleaning.

More Information About Digesters Around the Web

A biogas digester (also known as a biogas plant) is a large tank where Biogas is produced through the decomposition/breakdown of organic matter through a process called anaerobic digestion.

It’s called a digester because organic material is eaten and digested by bacteria to produce biogas.

Biogas is produced by the breaking down of organic, biodegradable waste or material (also known as biomass) such as vegetables, leaves, grass, weeds, leftover food scraps and such. When this organic breakdown happens, it produces a gas called biogas. via nrcs.usda.gov

A digester is a huge vessel [sometimes egg-shaped] where chemical or biological reactions are carried out. These are used in different types of process industries. via wikipedia

Egg-Shaped Digester Construction in Pinellas County, Florida, USA

Recent enhancements incorporated into the original design of the Egg-Shaped Digester (ESD™) anaerobic digester system have led to simplified mechanical systems, which have further improved the life cycle benefits of ESD systems.

Consequently, these improvements have allowed many owners to consider design-build construction of a digester facility.

A few of the benefits of this construction approach include single-source responsibility, accelerated construction schedule and lower capital cost.

This approach was recently implemented at a facility located in Pinellas County, Florida, USA. The County wanted to build a facility to treat solids that would produce a Class A product in a pelletized form, which could then be marketed and sold. via www.waterworld.com

Egg-Shaped Digesters for Sewage Sludge Treatment

The Egg-Shaped Digester is one of the most efficient and profitable anaerobic systems for sewage sludge treatment.

The ESD system also provides a smaller footprint, improved reliability, enhanced process control and reduced maintenance, all leading to reduced energy demand. via www.mcdermott.com

Anaerobic Digestion is used to stabilise both primary and secondary sludges, which settle out during aerobic wastewater treatment at Wastewater Treatment Facilities (Sewage Works).

The main output is a useful renewable (mostly methane) gas known as biogas, or biomethane when cleaned up. The gas can be used to power the equipment and offices at the wastewater treatment plant, and there may be some left over, which can supply local homes.

The sludges have a solids content of between 2-6% (that's 20-60 grams of Total Solids per litre).

About 70% of the mixed sludge is degradable, and in a standard single-stage CSTR reactor, up to 80% of it is digested, reducing the TS (Total Solids) by about 50%.

The mixed sewage sludge is rich in carbohydrates, lipids and proteins, but it is notoriously slow to digest.

The latest designs of these plants often include a pre-treatment stage where the touch incoming sludge cells are burst open to make them more easily digested, more rapidly in the digester.

The output is a liquid and solid mixture containing fibres. This can be used as liquid manure for land-spreading as a fertiliser and soil improver, as long as it has been adequately pasteurised during the process. But, unfortunately, most facility operators find that there is too much contamination with heavy metals and trace levels of other toxic chemicals for food crop application.

What Happens in an Egg-Shaped Digester?

The process of anaerobic digestion (AD) is what happens in any digester. AD is a collection of processes by which microorganisms break down biodegradable material in the absence of oxygen.

The process is used for industrial or domestic purposes to manage waste or to produce fuels. Much of the fermentation used industrially to produce food and drink products, as well as home fermentation, uses anaerobic digestion.

AD is widely used as a source of renewable energy. The process produces biogas, consisting of methane, carbon dioxide and traces of other ‘contaminant’ gases. This biogas can be used directly as fuel, in combined heat and power gas engines, or upgraded to natural gas-quality biomethane. The nutrient-rich digestate also produced can also be used as a fertiliser.

Egg-Shaped Digesters are Used in the Wet AD Process CSTR or Plug Flow – as Explained Below

The wet anaerobic digestion process is applied to liquid waste streams that are conveyable by liquid pumping. Sometimes wet systems are called Low Solids AD (LSAD).

The Wet AD process can be done in reactors of two main configurations, continuously stirred tank reactors (CSTR) and plug flow reactors.

The theory of the CSTR is that, through rigorous mixing, the composition of the contents of the reactor in any given spot in the tank is the same as in any other spot in the tank.

The theory of plug flow, on the other hand, is that the makeup of the contents at the head of the digester is different from that of the material leaving the digester, just as the material flows through the digester in a pattern like a plug through a pipe.

Wet systems commonly run at total solids levels between 2% and 8%. via biofermenergy

What Fuels Anaerobic Digestion?

Wet digester systems will often start with liquid manure or waste biosolids as the backbone of their feedstock load to provide a baseload buffering effect for enhanced process stability.

A key design parameter for any digester system is the overall loading rate. For any given project, no two digester suppliers will provide a system of exactly the same size. Loading rates are commonly expressed as the number of days of retention time or the quantity of organic matter applied to a given tank volume.

Common detention times for farm-based manure digesters are roughly 20-30 days.

Experience has shown that this time represents an optimum time where gas yield is maximised without over-designing the residence time. Facilities that are co-digesting more complex wastes that include fats and proteins will commonly have retention times higher than 30 days. via digester.com

FAQs About Egg-Shaped Anaerobic Digesters

What is an egg-shaped anaerobic digester?

An egg-shaped anaerobic digester (ESD) is a double-curved sludge treatment tank used to stabilise wastewater sludges and produce renewable biogas.

Why are some anaerobic digesters egg-shaped?

The egg shape improves mixing, reduces dead zones, minimises scum layers and lowers maintenance compared with cylindrical digesters.

What wastes are treated in egg-shaped digesters?

They mainly treat primary and secondary sewage sludges with 2–6% total solids, although the wet AD principles apply to other suitable liquid wastes.

How do egg-shaped digesters improve biogas production?

They provide superior mixing and contact between microbes and sludge, improving biodegradation and maximising methane production.

What are the key design features?

A conical bottom preventing grit accumulation, a small top surface area for scum control, and a continuous curved shell for reliable mixing.

Are egg-shaped digesters used in wet AD systems?

Yes. They operate at 2–8% TS as CSTR wet AD reactors producing biogas and nutrient-rich digestate.

What happens to sludge after digestion?

It becomes stabilised digestate, suitable for some land applications, though heavy metals often restrict use on food crops, and microplastics levels may be high.

Where were egg-shaped digesters first developed?

They originated in Germany in the 1950s and are now widely used in advanced wastewater treatment plants.

What are typical retention times?

About 20–30 days for simple sludges, with longer times for co-digestion of fats and proteins.

[Article first published August 2017: Updated December 2021, and FAQs added December 2025.]

Dear, I always wanted to know about this. Until today nobody told me. Thank you for posting this article.