Waste treatment plants face a major challenge: how to get more energy from sewage sludge. The current methods often fail to break down tough organic matter, which limits biogas output.

This problem costs plants money and wastes a chance to create more clean energy. Many experts now look for better ways to boost methane yields from this common waste product. That's why we were very interested to read a paper published yesterday on “Science Direct” that reports on a successful research project that massively improves biogas output using ChCl. ChCl is an inexpensive and environmentally friendly organic compound, so we were keen to spread the word by writing this article.

Introduction to Methane Production In Sludge (Yield Optimisation)

According to a paper published on “Science Direct”, the addition of Choline chloride offers a promising solution to the issue of low biogas yield. Recent studies show it can increase methane production by an amazing 151.1% when used at the right dose. This simple chemical works by breaking down the sticky substances that hold sludge together.

Unlike harsh heat or acid treatments, choline chloride is reportedly cheap and kind to the environment. It will greatly help to turn a waste problem into a valuable energy source.

The secret lies in how choline chloride changes the tiny life forms in sludge. Choline chloride shifts which microbes do the main work and helps them talk to each other better. According to the academic paper upon which this article is based, this leads to faster breakdown of waste and more biogas.

Want to know exactly how this happens?

For readers new to the topic, this article explains how choline chloride exposes more organic matter for microbial digestion and increases biogas yield.

Key Takeaways

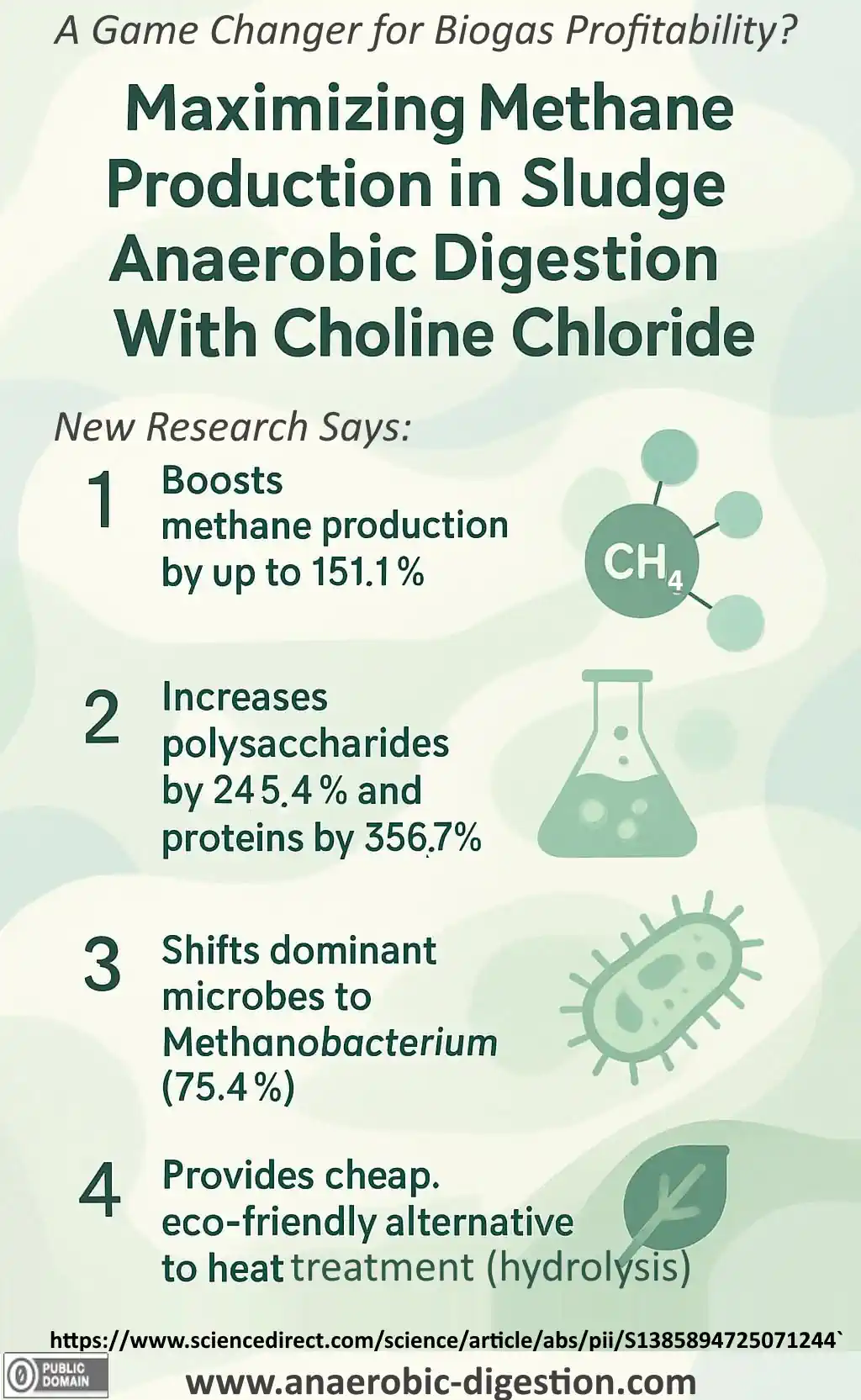

- Choline chloride boosts methane production from sewage sludge by up to 151.1%, according to a recent academic paper, when used at the right dose.

- The compound works by breaking down sticky substances in sludge, increasing bioavailable polysaccharides by 245.4% and proteins by 356.7%.

- Adding choline chloride shifts the dominant microbe types from Methanosarcina (69.6%) to more efficient Methanobacterium (75.4%).

- Unlike costly heat or acid treatments, choline chloride offers a cheap, eco-friendly solution that works in existing digesters.

- It is thought that the annual global waste activated-sludge produced at sewage works around the globe will exceed 100 million tonnes by 2025, making efficient treatment methods like this crucial.

Role of Choline Chloride in Enhancing Methane Production

Choline chloride acts as a powerful catalyst in sludge digestion, boosting methane yields by up to 40% in treatment plants. This simple compound breaks down waste faster while cutting costs for energy firms that turn sewage into green power.

What is Choline?

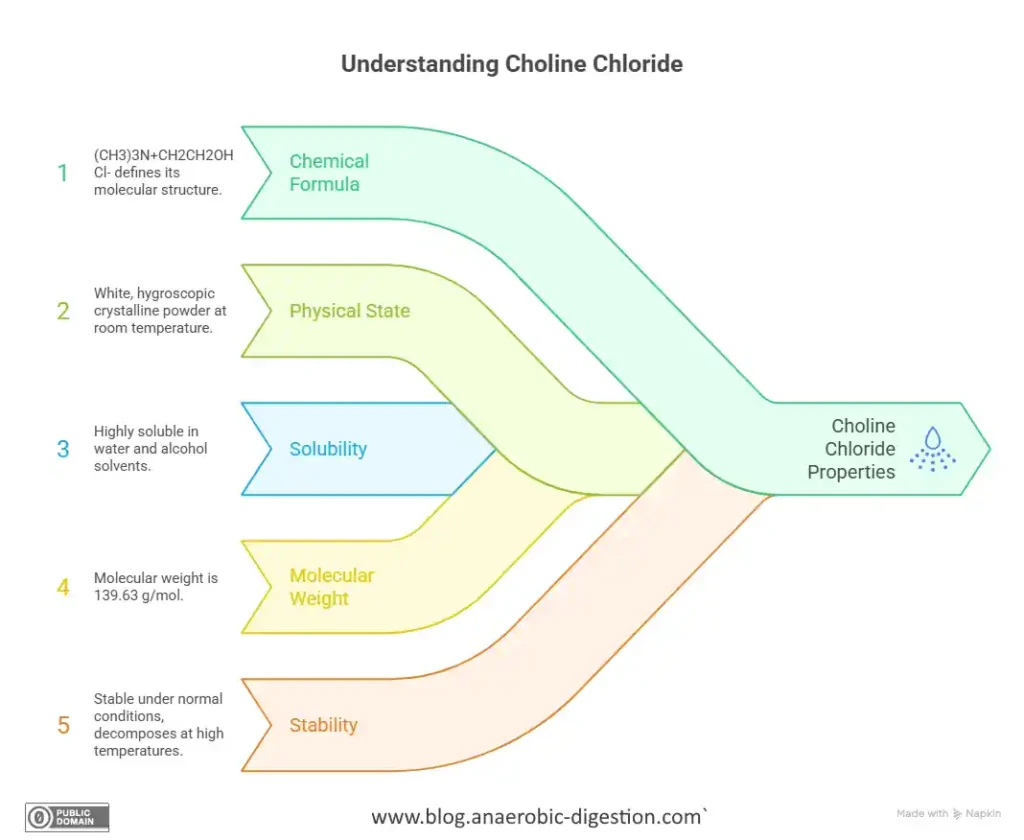

Choline is a cation with the chemical formula [(CH₃)₃NCH₂CH₂OH]⁺. Choline forms various salts, such as choline chloride and choline bitartrate. An essential nutrient for animals, it is a structural component of phospholipids and cell membranes. Source: Wikipedia

How Does Choline Chloride Promote Methane Production?

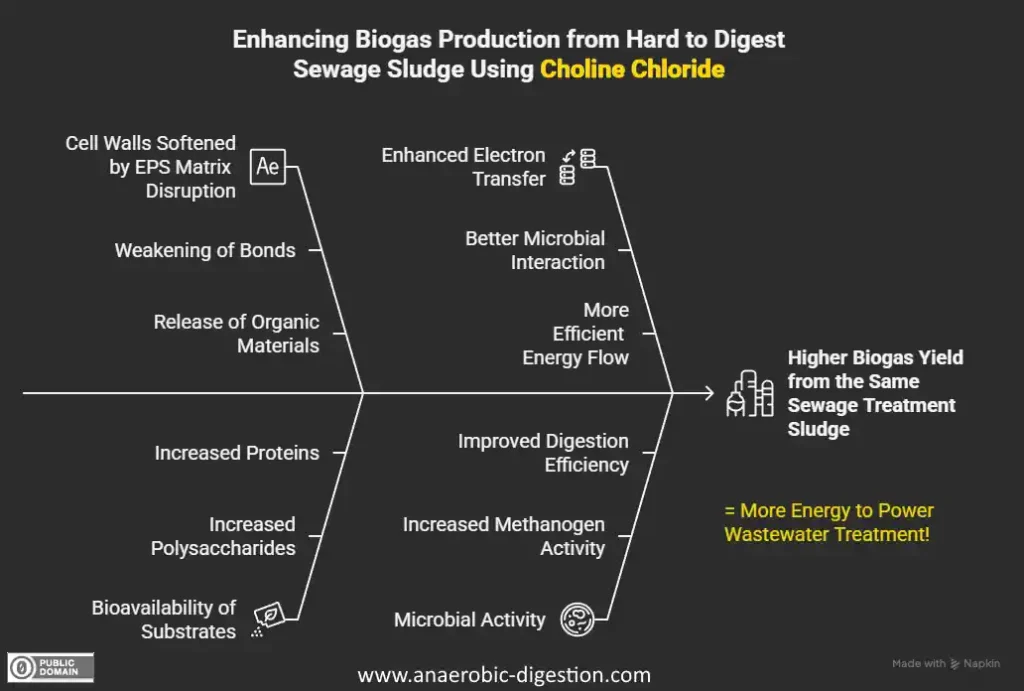

Choline chloride (ChCl) boosts methane production by breaking down the tough outer layers of wastewater sludge. It attacks extracellular polymeric substances (EPS), which normally protect bacteria in sewage sludge.

This breakdown lets enzymes reach more of the organic matter inside. The result is better hydrolysis, which turns complex materials into simpler compounds that acidogenic bacteria can use.

The disruption of EPS is like opening a locked door to release trapped energy potential within waste activated sludge.

ChCl creates a domino effect in anaerobic digestion. First, it improves the hydrolysis step. Then it speeds up acidification, where simple compounds become volatile fatty acids. These acids feed methanogens, the microbes that make methane gas.

This makes wastewater treatment plants more energy-efficient and helps turn waste into valuable biomethane.

What Are the Effects of Choline Chloride on Waste Activated Sludge Anaerobic Digestion?

Now that we understand how choline chloride boosts methane production, let's look at its specific effects on wastewater activated sludge during anaerobic digestion. The impact of choline chloride on sludge processing is said to be quite remarkable.

Tests carried out in the recent academic paper show it causes a massive 245.4% jump in bioavailable polysaccharide levels in the sludge. This means much more organic matter becomes available for microbes to convert into biogas.

Protein availability also skyrockets with choline chloride treatment. Research reveals a 356.7% increase in protein concentrations within the treated sludge. These proteins serve as vital food sources for methanogenic bacteria in anaerobic digesters.

The dramatic rise in both polysaccharides and proteins explains why biogas output improves so much. Sewage treatment plants can achieve higher energy production rates without needing expensive equipment upgrades or complex pretreatment steps.

The biodegradability of the waste material improves significantly, leading to more complete breakdown during the digestion process.

Mechanisms Behind Choline Chloride's Impact

Choline chloride works through five key actions that boost methane yields in sludge digestion. These actions change how microbes break down waste and create a better environment for the bacteria that make methane gas.

How Does Choline Chloride Disrupt Extracellular Polymeric Substances?

Extracellular polymeric substances (EPS) form a protective barrier around microbes in wastewater treatment works, activated sludge, limiting biogas production. Choline chloride (ChCl) breaks down this barrier through a direct chemical attack on the EPS structure.

This disruption happens as ChCl weakens the bonds between polysaccharides and proteins that make up the EPS matrix. The process releases trapped organic materials that would otherwise remain unavailable for digestion.

The key to maximizing methane yield lies in making the invisible accessible – breaking down barriers that keep valuable substrates locked away from hungry microorganisms.

ChCl acts like a key that unlocks the door to hidden nutrients within sludge cells. After treatment, the bioavailable polysaccharides and proteins increase by significant amounts. These newly freed compounds serve as perfect food sources for methane-producing microbes.

The breakdown of EPS also improves the transfer of electrons between different microbial groups, creating better teamwork in the anaerobic digestion process.

How Does Choline Chloride Increase Bioavailable Polysaccharides and Proteins – According to a Paper on Maximising Methane Production from WwTW Sludge

The disruption of extracellular polymeric substances by choline chloride leads to a major boost in nutrient availability. Choline chloride breaks down the tough outer layers of wastewater treatment works activated sludge, which frees up trapped organic matter.

This process creates a stunning 245.4% increase in bioavailable polysaccharide levels in the sludge. The chemical works by weakening the bonds that hold complex carbohydrates together, making them easier for microbes to digest during anaerobic digestion.

These freed polysaccharides serve as prime food sources for the bacteria that start the methane production chain.

Protein release also jumps dramatically with choline chloride treatment, showing a 356.7% increase in the sludge mixture. Choline chloride helps break down cell walls and membranes that normally lock away these valuable proteins.

The newly available proteins supply essential amino acids and nitrogen that methanogens need for growth and activity. More bioavailable proteins mean faster microbial growth rates and more active methanogenic communities.

This enhanced nutrient access creates ideal conditions for the microorganisms involved in sewage sludge biogas production, which results in much higher methane yields from the same amount of waste.

How Does Choline Chloride Shift Dominant Methanogen Types According to this Paper on Maximising Methane Production from WwTW Sludge?

Choline chloride significantly alters the composition of methane-producing microorganisms in sewage sludge. Research indicates that in the absence of choline chloride, acetoclastic Methanosarcina constitutes 69.6% of the methanogens.

Upon introduction of choline chloride, hydrogenotrophic Methanobacterium becomes predominant at 75.4%. This shift is significant because hydrogenotrophic methanogens are more effective in the complex waste composition found in sludge.

They convert hydrogen and carbon dioxide into methane more efficiently than other microorganisms can process fatty acids.

This microbial change enhances the overall methane production from waste activated sludge. Methanobacterium flourishes in the new environment created by choline chloride, which decomposes complex organic compounds into simpler forms.

The increased presence of these microorganisms accelerates the biodegradation process and increases biogas yields. Gas chromatograph analyses confirm higher methane content in the resulting biogas, enhancing its value for energy recovery systems.

In the following section, we will examine how choline chloride influences key genes and improves microbial adaptability.

How Does Choline Chloride Upregulate Key Genes and Improve Microbial Adaptability According to a Paper on Maximising Methane Production from WwTW Sludge?

Choline chloride boosts methane production by changing how microbes work at the genetic level. Microbes exposed to this compound show increased activity in key genes like ACAT and glnA, which form part of two-component systems vital for sensing changes in their surroundings.

These systems help bacteria adapt to new conditions in the anaerobic digestion process. The compound also turns on genes linked to quorum sensing, such as secY and rhlB, which let microbes talk to each other.

This genetic shift makes the microbial community more stable during sewage sludge breakdown. The bugs become better at handling stress and can work together more smoothly to break down waste.

As a result, the whole system produces more biogas with higher methane content. The improved microbial teamwork creates a more efficient circular economy within waste treatment plants, turning what was once just sludge into valuable renewable energy.

How Does Choline Chloride Enhance Extracellular Electron Transfer and Symbiosis?

According to a “Science Direct” paper on Maximising Methane Production from WwTW Sludge, Choline chloride boosts extracellular electron transfer in sewage biogas systems by turning on key genes. Research shows it activates pilA genes that create e-pili, tiny wire-like structures that help microbes share electrons.

These connections let different bugs work together during waste breakdown and methane production. The result is more efficient energy transfer throughout the microbial community.

This compound also builds stronger partnerships between different microbes in anaerobic sludge. Studies reveal a 63.07% jump in positive relationships and a linkage density of 3.36 when choline chloride is added.

These numbers matter because better teamwork among bacteria and methanogens means faster waste processing and higher biogas yields. The improved symbiosis creates a more stable digestion process that can handle changes in organic wastes and maintain steady methane production.

Feasibility and Environmental Impact of Using Choline Chloride

Choline chloride offers a cost-effective way to boost methane yields from sewage sludge while reducing waste treatment costs. This green chemical helps tackle the growing global challenge of wastewater treatment works activated sludge management in a more earth-friendly manner than energy-intensive methods like incineration.

What Is the Global Scale of Waste Activated Sludge Production?

Disposal of the extended-aeration wastewater treatment activated sludge (WAS) that the global standard sewage works process produces has grown into a major global challenge for those wastewater treatment plants worldwide. Experts project that WAS production will exceed 100 million tonnes by 2025, creating both problems and chances for resource recovery.

This massive volume comes from municipal wastewater treatment systems that clean sewage through biological processes. The sludge contains organic matter that can be broken down through anaerobic digestion to produce biogas.

The scale of WAS production varies across regions based on population density and industrial activity. Countries with advanced sewage systems generate more sludge that requires proper disposal or treatment.

Traditional methods like landfilling and incineration face growing restrictions due to their environmental impact. This has pushed the water treatment industry toward sustainable options such as anaerobic digestion, which turns waste into energy through methanogenesis while reducing chemical oxygen demand.

The rising volumes make finding efficient solutions for WAS management more urgent than ever.

Why Is Anaerobic Digestion a Sustainable Technology?

Anaerobic digestion stands as a truly sustainable technology in our renewable energy landscape. This process utilises organic matter and nutrients in waste activated sludge (WAS) while producing valuable biogas with high methane content.

Unlike other waste treatment methods, anaerobic digestion creates a closed loop system where waste becomes a resource. The process occurs in oxygen-free tanks where micro-organisms break down biowastes and convert them into energy-rich biogas and nutrient-dense digestates.

These outputs serve dual purposes: biogas provides clean energy while digestates can improve soil health as fertilisers.

The sustainability credentials of anaerobic digestion extend beyond waste management. Biogas plants reduce greenhouse gas emissions by capturing methane that would otherwise enter the atmosphere from decomposing waste.

The technology also requires less energy input compared to aerobic treatment processes used in conventional wastewater treatment plants. In fact, many sewage works are entirely powered by their biogas output already, with a surplus they sell to the local electricity grid. So, many municipal wastewater treatment facilities worldwide have already adopted this approach to handle sewage sludge and food waste efficiently.

Now, let's examine why traditional pretreatment methods fall short compared to choline chloride solutions.

What Are the Limitations of Traditional Pretreatment Methods Compared to Choline Chloride?

Traditional pretreatment methods for waste activated sludge suffer from major drawbacks that limit their real-world use. Physical methods like thermal hydrolysis and ultrasonic treatment demand huge energy inputs, making them costly for wastewater treatment plants.

Biological approaches for sewage sludge digestion need long retention times because the sludge has already been treated during primary aerobic treatment. Only the hard to break-down cells are left. For that reason, biogas digestion often fails to break down complex lignocellulosic biomass fully. These methods also create harmful by-products that can hurt the anaerobic digestion process and reduce methane yields.

Choline chloride offers a superior alternative with much lower energy needs and costs. This eco-friendly compound disrupts the sludge structure without the harsh chemicals used in conventional treatments.

The C/N ratio improves significantly with ChCl addition, boosting microbial activity and methane generation. Unlike physical methods that require special equipment, ChCl can be added directly to existing digesters with minimal changes to infrastructure.

This makes it an ideal option for upgrading biosolids management at municipal wastewater treatment plants. Next, we'll explore why anaerobic digestion represents a sustainable technology for our future energy needs.

Why Is Choline Chloride an Affordable and Eco-Friendly Solution?

Unlike costly pretreatment methods, choline chloride (ChCl) reportedly offers a budget-friendly option for wastewater treatment plants. This organic compound works under mild conditions, which cuts energy costs in anaerobic digestion plants.

ChCl reportedly boosts methane production without harsh chemicals or high heat, making it safer for workers and the environment. The compound breaks down wastewater activated sludge more fully, which means less leftover material needs disposal.

ChCl stands out for its dual benefits in biorefining processes. It enhances substrate bioavailability without complex equipment or toxic byproducts. This matters greatly in mesophilic digestion systems where other additives might disrupt the delicate microbial balance.

The low cost of ChCl makes it perfect for large-scale sludge processing, helping turn waste into valuable biogas rather than filling landfills. Its eco-friendly nature fits well with global efforts to create greener waste management solutions.

Conclusion

Choline chloride stands out as a game-changer for waste sludge processing. This simple compound boosts methane yields by 151%, far outperforming traditional methods. It works by breaking down tough cell structures and shifting microbe communities toward more efficient gas production.

The cost benefits make sense too, as treatment plants can generate more energy while spending less on chemicals. For our planet's future, this approach offers a win-win solution that turns waste problems into clean energy answers.

FAQs – Maximising Methane Production (Biogas Yield) from Wastewater Treatment Works Sludge

1. What is anaerobic digestion of sewage sludge and how does choline chloride help?

Anaerobic digestion breaks down sewage sludge without oxygen to make biogas. Choline chloride boosts this process by helping bacteria work better during acidogenesis. It increases methane output by improving the breakdown of tough materials like lignocellulose biomass.

2. How does choline chloride affect alkalinity in the digestion process?

Choline chloride helps maintain proper alkalinity levels in digesters. This balance is key for the bacteria that produce methane. Good alkalinity prevents problems that can slow down the decomposition of waste materials.

3. Can choline chloride improve the treatment of household waste in WWTPs?

Yes, adding choline chloride to waste treatment plants helps break down household waste more completely. It works well in systems like anaerobic membrane bioreactors. The process creates more energy while reducing leftover solids.

4. Does choline chloride affect the breakdown of lignin in the sludge?

Choline chloride makes lignin more soluble, which is normally hard to break down in anaerobic conditions. This helps bacteria access more of the organic matter. The result is less waste and more methane gas production.

5. How does choline chloride compare to other additives like FeCl3?

Unlike FeCl3 which works by oxidising compounds, choline chloride improves bacterial activity directly. It's often more effective than iron compounds for boosting methane yields. Choline chloride also doesn't interfere with the recycling of digested materials.

6. What happens to humic acids and fulvic acids when using choline chloride?

Choline chloride reduces the negative effects of humic and fulvic acids on the digestion process. These acids can slow down bacteria, but choline chloride helps overcome this problem. The treatment works by changing how these acids interact with the microbial communities in the digester.

Additional Insights

To maximise methane production in sludge anaerobic digestion, several strategies can be employed, including optimising operating parameters, pretreating the sludge, and co-digesting with other organic wastes. Enhancing microbial activity and optimising digester conditions are key to boosting methane yield.

1. Optimising Operating Parameters:

- Anaerobic digestion is sensitive to temperature and pH. Mesophilic conditions (around 35°C) are common, but thermophilic digestion (around 55°C) can offer higher methane production rates. Adjusting pH to the optimal range for the microbial community is crucial. For example, one study optimised temperature, pH, and hydrogen peroxide concentration for maximising methane production and solubilisation, with the optimal parameters being 83.2°C, pH 10.6, and 34.8 mg H2O2/g TS.

- Adequate HRT is needed for microbial digestion to occur. Longer HRTs generally lead to higher methane yields, but there is a point of diminishing returns.

- Finding the right balance between OLR and HRT is important. High OLR can lead to volatile fatty acid (VFA) accumulation and digester instability, while low OLR can reduce methane production.

- Proper mixing ensures that micro-organisms are in contact with the substrate and that nutrients are evenly distributed.

2. Sludge Pretreatment:

- Ultrasound and heat can disrupt the sludge structure and increase the surface area available for microbial attack.

- Alkaline pretreatment, using chemicals like hydrogen peroxide or potassium permanganate, can solubilise organic matter and enhance biodegradability.

- Using enzymes like lipase can help break down complex organic matter into simpler compounds that are more readily digested by micro-organisms.

- Combining different pretreatment methods can lead to synergistic effects and greater improvements in methane production.

3. Co-digestion:

- Co-digesting sewage sludge with other organic materials like food waste, agricultural residues, or agro-industrial wastes can improve methane yield and process stability.

- For example, adding organic materials like biochar or activated carbon can enhance volatile fatty acid consumption and improve methane production.

4. Enhancing Microbial Activity:

- Introducing specific microbial cultures can enhance the digestion process, especially if the existing microbial community is not optimal.

- DIET is a process where micro-organisms exchange electrons directly, which can enhance methane production. Adding conductive materials like biochar or activated carbon can facilitate DIET.

- Applying weak magnetic fields can create a favourable environment for micro-organism growth and enhance methane production.

5. Other Strategies:

- MEC-AD (Microbial Electrochemical Anaerobic Digestion) can enhance methane production by using electrodes to facilitate electron transfer.

- Ensuring adequate levels of essential nutrients like nitrogen and phosphorus can support micro-organism growth and activity.

- Identifying and mitigating the effects of inhibitory substances like ammonia or sulphide can improve digester performance.

By carefully considering and optimising these factors, it is possible to significantly enhance methane production from sludge anaerobic digestion, leading to increased biogas output and improved waste treatment.

Disclaimer: This content is for informational and educational purposes only and is not a substitute for professional advice. Data provided is based on research studies and is summarised for educational purposes.