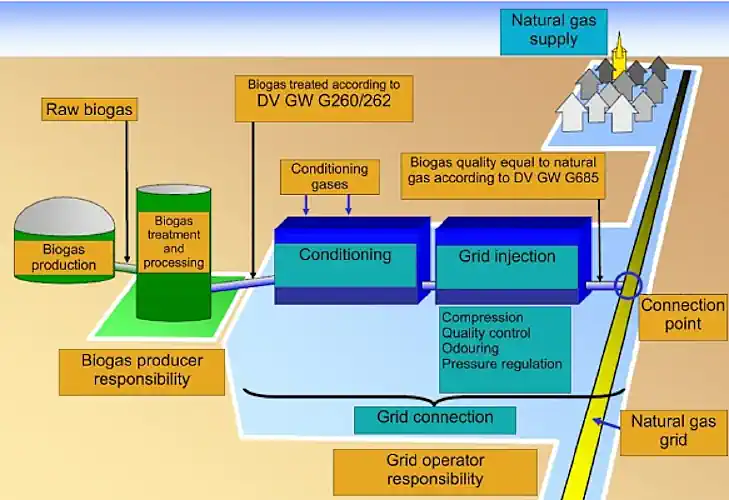

Biomethane grid injection is the process of upgrading biogas from organic waste into a gas of similar quality to natural gas and feeding it into the existing gas distribution network.

It involves cleaning and purifying the biogas to remove impurities like carbon dioxide and hydrogen sulphide, then compressing it to meet the pressure and quality standards for injection into the grid.

This is a highly efficient way to use this renewable energy source. It is more energy-efficient than using the raw biogas for electricity generation alone, and many older biogas plants are being converted to this technology.

Key Takeaways

- Biomethane grid injection provides a carbon-neutral alternative to natural gas, utilising existing infrastructure while reducing greenhouse gas emissions by up to 85%

- The IEA forecasts green gas growth at 15% annually until 2035 and 8.9% annually to 2050 for achieving net-zero goals

- Successful biomethane injection requires specialised purification processes to remove contaminants and meet strict gas grid quality standards

- Grid entry units contain critical components, including analysers, fiscal metering, and emergency systems that ensure safe, compliant integration

- The World Biogas Association highlights biomethane as a “double win” that provides reliable energy while removing greenhouse gases from the atmosphere

The transition to renewable energy continues to accelerate worldwide, with biomethane gas grid injection emerging as a crucial component in our sustainable energy future. This renewable gas solution represents one of the most practical methods for decarbonising existing natural gas infrastructure without requiring massive new investment in distribution systems.

As highlighted in a recent press release, the World Biogas Association welcomes the International Energy Agency's “bullish” forecasts for green gas in the energy transition.

“These bullish forecasts for green gas underline the increasing extent to which policy-makers are recognising the unique benefits of a fuel that is available at all times, complementing solar and wind power,”

said Charlotte Morton OBE, WBA Chief Executive.

“In addition, modern green gas involves the cheapest means of removing global warming gases from the atmosphere. Green gas is a double win.”

Biomethane: The Natural Gas Alternative Transforming Our Energy Grid

Biomethane represents a renewable alternative to conventional natural gas that can be seamlessly integrated into existing gas infrastructure. Unlike other renewable energy sources that require new delivery systems, biomethane's molecular similarity to natural gas allows it to utilize the extensive pipeline networks already in place throughout developed nations. This compatibility makes it an immediately deployable solution for reducing carbon emissions while maintaining energy security.

The IEA forecasts that green gas will grow by an impressive 15% annually until 2035 and 8.9% annually to 2050 if the world is to achieve net-zero targets. What's particularly noteworthy is that across all projected scenarios, green gas is expected to grow more rapidly than the average growth of renewables generally, and significantly faster than overall energy demand.

What Makes Biomethane a Renewable Powerhouse

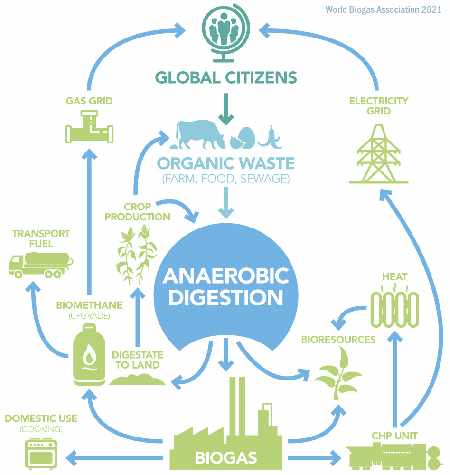

Biomethane earns its renewable status through its production cycle, which essentially captures methane that would otherwise enter the atmosphere as a potent greenhouse gas. Produced through anaerobic digestion of organic materials—including agricultural waste, food industry byproducts, municipal solid waste, and wastewater—biomethane represents a true circular economy solution. When organic matter decomposes in an oxygen-free environment, it produces biogas that can be upgraded to biomethane.

What sets biomethane apart from other renewable energy sources is its dispatchability—it can be produced, stored, and used on demand, unlike solar or wind power, which depend on weather conditions. This characteristic makes biomethane particularly valuable for balancing electricity grids with high penetration of intermittent renewables. Additionally, the European biomethane market demonstrates impressive scale, with over 40 TWh injected into natural gas grids annually from approximately 1,200 production sites across the continent.

How It Differs From Traditional Natural Gas

While biomethane and natural gas share the same primary component—methane (CH4)—their origins and environmental impacts couldn't be more different. Biomethane is produced from organic materials through processes like anaerobic digestion, offering a renewable alternative to fossil fuels. Natural gas, on the other hand, is a fossil fuel formed over millions of years from decomposed plant and animal matter, extracted from underground deposits. Its combustion releases carbon that has been sequestered for geological timeframes, contributing to net atmospheric carbon increases.

Biomethane, conversely, is produced from contemporary organic matter, creating a short carbon cycle. The carbon dioxide released during combustion only returns carbon to the atmosphere that was recently captured by plants, resulting in a carbon-neutral or even carbon-negative footprint when considering the emissions avoided from natural decomposition. This fundamental difference makes biomethane a key player in decarbonization strategies, offering a drop-in replacement for natural gas with up to 85% lower lifecycle greenhouse gas emissions.

How Biomethane Gas Grid Injection Works

Injecting biomethane into the natural gas grid involves a sophisticated process that ensures the renewable gas meets the same rigorous standards as conventional natural gas. The integration pathway begins with raw biogas production and culminates in grid injection through specialised equipment that monitors and controls gas quality, pressure, and flow. This multi-stage process transforms what would otherwise be waste materials into a valuable energy resource that flows through the same pipelines that have traditionally carried fossil-based natural gas.

From Organic Waste to Pipeline-Ready Gas

The journey from waste to energy begins with the collection and preparation of organic feedstocks. These materials are then fed into an anaerobic digester—essentially a large, oxygen-free tank where microorganisms break down the organic matter to produce biogas. This raw biogas typically contains 50-65% methane, with the remainder primarily consisting of carbon dioxide, water vapour, and trace contaminants like hydrogen sulfide and siloxanes.

For grid injection purposes, this biogas must undergo a critical upgrading process to increase its methane content to match natural gas specifications (typically 95-98% methane). Several technologies can accomplish this separation, including water scrubbing, pressure swing adsorption, membrane separation, and amine scrubbing. Each method employs different physical or chemical processes to selectively remove carbon dioxide and other impurities from the biogas, resulting in high-purity biomethane suitable for pipeline injection.

Critical Purification and Upgrading Processes

The purification of biogas into grid-quality biomethane requires sophisticated treatment systems that target specific contaminants. Initially, raw biogas undergoes primary cleaning to remove hydrogen sulfide, water vapour, and particulates that could damage downstream equipment.

This is followed by the critical upgrading phase, where carbon dioxide is separated from methane to increase energy content. Technologies such as pressure swing adsorption (PSA), water scrubbing, membrane separation, and chemical absorption systems each offer different advantages depending on plant scale and local requirements.

The choice of upgrading technology significantly impacts both capital expenditure and operating costs. Water scrubbing tends to be favoured for larger installations due to its scalability, while membrane technology offers advantages for smaller operations with its modular design and lower energy consumption.

Regardless of the chosen method, continuous monitoring ensures the gas meets strict specifications before it ever reaches the grid connection point. Modern upgrading facilities typically achieve methane recovery rates exceeding 99%, maximising both environmental and economic benefits. For more insights, explore biomethane developments in Northern Ireland.

Gas Quality Requirements for Grid Acceptance

For successful integration into natural gas networks, biomethane must meet stringent quality parameters that vary slightly between different national gas grid operators. The calorific value must typically fall between 36-41 MJ/m³, with methane content above 95% to ensure proper combustion characteristics for end-users. Equally important are the maximum allowable limits for oxygen (typically <0.5%), carbon dioxide (<2.5%), hydrogen sulfide (<5 mg/m³), and water dew point (usually -8°C at maximum operating pressure).

Grid operators also enforce limits on siloxanes, ammonia, and volatile organic compounds that could cause equipment damage or combustion issues. Meeting these requirements demands precision engineering and continuous quality control. Modern biomethane plants incorporate real-time gas chromatography and specialised analysers that constantly evaluate gas composition, automatically diverting product that falls outside specifications away from grid injection.

This ensures that only compliant biomethane enters the natural gas infrastructure, protecting both the network integrity and end-user equipment. For more information on optimising biogas production, consider reading about biogas yield analysis best practices.

Compression and Pressure Control Systems

Before biomethane can enter the gas grid, its pressure must be precisely regulated to match the receiving pipeline's operating pressure. Depending on the injection point—whether into local distribution networks (0.5-10 bar) or transmission systems (up to 80 bar)—different compression strategies are required. Multi-stage compressors with intercooling typically provide the most efficient solution for achieving the necessary pressure while minimising energy consumption. For more information, you can explore Green Gas Solutions for comprehensive insights.

Beyond mere compression, sophisticated pressure control systems actively manage the differential pressure between the biomethane supply and the grid. These systems incorporate specialised regulators, safety valve trains, and control logic that respond in real-time to fluctuations in grid pressure.

During periods of low gas demand, when grid pressures rise, advanced control systems can modulate injection rates or temporarily redirect gas to storage to ensure continuous operation. This dynamic pressure management represents one of the most challenging yet essential aspects of reliable grid injection.

Essential Components of Grid Entry Units

The grid entry unit (GEU) serves as the critical interface between biomethane production facilities and the gas network, housing all necessary equipment for monitoring, controlling, and safely transferring the renewable gas. These highly engineered systems integrate gas quality measurement, fiscal metering, pressure regulation, and safety systems into a compact installation that ensures regulatory compliance. Modern GEUs typically feature a modular design that allows for standardisation while accommodating site-specific requirements, reducing both installation time and engineering costs.

“Renewable Gas Grid Injection” from process.honeywell.com and used with no modifications.

Analyser Packages for Quality Monitoring

At the heart of every grid entry unit lies a comprehensive suite of gas analysers that continuously verify biomethane composition against grid specifications. These systems typically include gas chromatographs for detailed composition analysis, laser-based detectors for rapid methane and carbon dioxide measurement, and specialised sensors for trace contaminants.

The analyser package represents the grid operator's primary quality assurance mechanism, with most systems programmed to automatically close injection valves within seconds if parameters exceed allowable limits.

Beyond regulatory compliance, these analyser systems provide valuable operational data that helps plant operators optimise their upgrading processes. By tracking trends in gas composition, operators can identify early warning signs of upgrading system deterioration or feedstock variability issues. Many modern analyser packages incorporate cloud connectivity that enables remote monitoring and predictive maintenance, significantly improving operational reliability while reducing the need for constant on-site supervision.

Fiscal Metering Systems

Accurate measurement of biomethane volumes and energy content is essential for both regulatory compliance and financial settlement between producers and grid operators. Fiscal metering systems employ ultrasonic or turbine flow meters calibrated to reference conditions (typically 0°C and 1.01325 bar), with automatic temperature and pressure compensation. These systems must meet national metrology standards and are regularly calibrated according to strict protocols.

Energy content calculation integrates real-time calorific value measurements with volume data to determine the actual energy injected into the grid—typically expressed in kilowatt-hours (kWh) or megajoules (MJ). This precise energy accounting forms the basis for renewable incentive payments, making meter accuracy directly linked to project economics. Most jurisdictions require redundant measurement systems with automatic cross-checking to ensure reliability, with data securely logged for audit purposes and billing reconciliation.

“biogas into natural gas grid …” from www.researchgate.net and used with no modifications.

Emergency Shutdown Systems

Safety remains paramount in biomethane grid injection, with sophisticated emergency shutdown systems designed to protect both the gas network and the surrounding environment. These systems incorporate multiple layers of protection, including automated valve closure triggered by gas quality deviations, pressure anomalies, or flame detection. Redundant sensors and fail-safe actuators ensure reliable operation even during power outages or component failures.

The emergency response architecture typically includes a programmable logic controller (PLC) that continuously monitors all critical parameters and can initiate controlled shutdown sequences within milliseconds of detecting unsafe conditions. Most systems also feature manual emergency stops and remote shutdown capabilities that allow grid operators to immediately isolate the injection point if necessary. This comprehensive safety approach, combined with regular emergency response testing, ensures that biomethane injection meets the same rigorous safety standards as conventional natural gas infrastructure.

Control Room and Monitoring Solutions

Modern biomethane grid injection facilities incorporate sophisticated control room systems that provide operators with comprehensive visualisation and management capabilities. These SCADA (Supervisory Control and Data Acquisition) platforms integrate data from every subsystem—from anaerobic digestion to grid injection—into intuitive interfaces that highlight key performance indicators while enabling rapid response to process deviations. Advanced facilities feature predictive analytics that can identify potential issues before they affect production, significantly improving operational efficiency.

Remote monitoring capabilities have revolutionised biomethane plant management, allowing skilled technicians to supervise multiple facilities from centralised locations. Secure cloud-based solutions provide real-time access to operational data via smartphones and tablets, enabling rapid response even during off-hours. Many systems now incorporate automated alert protocols that escalate notifications based on severity, ensuring appropriate response while minimising false alarms. This connectivity also facilitates regular performance benchmarking against similar installations, helping operators identify optimisation opportunities throughout the plant lifecycle.

Environmental Benefits That Drive Biomethane Adoption

The environmental case for biomethane grid injection extends far beyond simple carbon reduction. When organic waste is diverted from landfills or open storage to produce biomethane, multiple environmental benefits accumulate simultaneously.

Methane emissions that would otherwise contribute significantly to global warming are captured and utilised, while the digestate byproduct provides a valuable soil amendment that can replace synthetic fertilisers. This holistic approach creates a genuinely circular economy solution with cascading positive impacts across multiple environmental indicators.

Lord Callanan opened the 2021 Anaerobic Digestion and Bioresources Association (ADBA) National Conference on 14 December 2021 with a clear message about the value of biomethane in helping the UK to meet its Net Zero targets and fulfil its ambition to level up the country’s economy.

Carbon Footprint Reduction Potential

Biomethane demonstrates remarkable greenhouse gas reduction capabilities when compared to conventional natural gas. Life cycle assessments consistently show carbon footprint reductions of 80-95% when accounting for avoided methane emissions from waste decomposition and the displacement of fossil-derived natural gas. For a typical agricultural waste-to-grid biomethane facility processing 50,000 tons of feedstock annually, this translates to approximately 7,000-9,000 tons of CO₂ equivalent emissions avoided each year—comparable to removing over 1,500 cars from the road. Learn more about how anaerobic digestion reduces landfill reliance.

The carbon intensity of biomethane varies significantly based on feedstock source, with wastewater treatment plants typically achieving the lowest carbon footprints due to the mandatory processing of their primary feedstock. Food waste and agricultural residue projects follow closely behind, while purpose-grown energy crops generally demonstrate higher, though still favourable, carbon intensities. This variability creates a natural market-based incentive for developing the most environmentally beneficial projects first, maximising climate impact per investment dollar.

Converting Waste Streams into Value

Beyond carbon benefits, biomethane production transforms problematic waste streams into valuable energy resources. Food waste that would otherwise occupy limited landfill capacity becomes a clean energy source, while agricultural residues that might create water quality issues if improperly managed instead generate revenue for farming operations. This waste-to-value proposition fundamentally changes the economics of waste management, transforming disposal costs into potential income streams.

The digestate byproduct of biomethane production represents another significant environmental benefit. Rich in nutrients but stabilised through the digestion process, this material makes an excellent soil amendment that builds organic carbon content while reducing the need for synthetic fertilisers. When properly processed and applied, digestate closes the nutrient cycle by returning phosphorus and nitrogen to agricultural soils in plant-available forms. Advanced facilities are increasingly integrating nutrient recovery systems that produce concentrated organic fertilisers, further enhancing the circular economy aspects of biomethane production.

Supporting Circular Economy Principles

Biomethane grid injection exemplifies circular economy principles by transforming what society has traditionally treated as waste into multiple value streams. The organic carbon in food scraps, agricultural residues, and sewage becomes renewable energy, while the nutrients and remaining organic matter return to soil as amendments. This closes loops that have historically remained open in our linear economic systems, reducing both resource consumption and waste production simultaneously.

The distributed nature of biomethane production creates additional circular economy benefits by connecting urban waste streams with rural energy and nutrient needs. City food waste becomes rural energy and fertiliser, while agricultural residues become urban cooking and heating fuel. These urban-rural partnerships create economic interdependencies that strengthen local economies while reducing transportation impacts. As circular economy principles gain traction in policy and business planning, biomethane projects increasingly serve as flagship examples of practical implementation with measurable environmental and economic benefits.

Technical Challenges and Solutions in Biomethane Injection

While biomethane grid injection offers compelling environmental and economic benefits, several technical challenges must be overcome to ensure successful implementation. From initial gas cleaning to maintaining stable injection rates, these challenges require sophisticated engineering solutions that have evolved significantly over the past decade. Understanding these technical hurdles and their proven solutions helps project developers avoid costly pitfalls while accelerating the deployment of this renewable gas resource.

Handling Hydrogen Sulfide Contamination

Hydrogen sulphide (H₂S) represents one of the most persistent challenges in biomethane production, particularly from high-protein feedstocks like food waste or certain agricultural residues. This corrosive, odorous compound must be reduced to extremely low levels (typically below 5 mg/m³) before grid injection. Traditional approaches using iron oxide media beds provide reliable removal but generate solid waste requiring special handling. Modern biological desulfurization systems offer more sustainable alternatives by using specialised bacteria to convert H₂S to elemental sulfur, which can be recovered as a valuable agricultural amendment.

The choice of H₂S removal technology significantly impacts both capital costs and operational expenses. Biological systems typically demonstrate lower operating costs but require careful management of bacterial populations and reaction conditions. Chemical scrubbing using caustic solutions provides a rapid response to fluctuating H₂S levels but generates liquid waste streams requiring treatment. Many installations now implement multi-stage approaches that combine biological treatment for bulk removal with polishing steps using activated carbon or specialised media, optimising both performance and cost-effectiveness across varying operating conditions.

Meeting Strict Methane Content Requirements

Grid operators typically require biomethane to contain at least 95-97% methane to ensure consistent combustion properties for end users. Achieving this purity level economically presents significant engineering challenges, particularly when processing feedstocks that generate biogas with high CO₂ content. Water scrubbing remains popular for larger installations due to its operational simplicity, but physical solvent systems and membrane technologies increasingly compete on efficiency and operational flexibility. For more information on these solutions, visit Green Gas Solutions.

Beyond the primary upgrading technology, methane slip—the unintentional release of methane during upgrading—represents a critical challenge that can undermine environmental benefits if not properly managed. Best practices now include thermal or catalytic oxidation of off-gases to ensure methane slip remains below 0.5%. Advanced membrane systems and optimised pressure swing adsorption configurations have dramatically reduced methane losses while improving energy efficiency, making grid injection increasingly viable even for smaller-scale operations. These technological improvements continue to expand the range of economically viable biomethane projects while enhancing their environmental performance.

Managing Siloxanes and Other Impurities

Siloxanes—silicon-containing compounds commonly found in personal care products—present unique challenges for biomethane producers using wastewater or municipal solid waste feedstocks. When combusted, these compounds form silica deposits that can damage engines, turbines, and burners. Removing siloxanes typically requires specialised activated carbon media or cryogenic treatment systems that add significant complexity and cost to gas upgrading plants. Continuous monitoring using gas chromatography or specialised siloxane analysers ensures treatment effectiveness while optimising media replacement schedules.

Other trace contaminants requiring management include ammonia, halogenated compounds, and volatile organic compounds (VOCs). These components must be reduced to parts-per-billion levels to meet grid specifications and protect downstream infrastructure. Multi-barrier approaches incorporating refrigeration, activated carbon filtration, and specialised chemical scrubbing provide comprehensive removal of these diverse contaminants. The specific treatment train varies based on feedstock composition, with municipal solid waste typically requiring more extensive treatment than agricultural residues. This customisation ensures cost-effective compliance while maintaining production economics. Learn more about solutions for managing trace contaminants.

The Economic Case for Biomethane Grid Injection

The financial viability of biomethane grid injection projects depends on a complex interplay of capital expenditure, operating costs, feedstock pricing, and revenue streams that vary significantly between regions and regulatory frameworks. While environmental benefits drive policy support, practical implementation requires solid business models that deliver acceptable returns on investment. Understanding these economic drivers helps stakeholders identify optimal project configurations while highlighting areas where policy adjustments could accelerate the adoption of this renewable gas resource.

Operational Cost Considerations

The production cost structure for biomethane facilities differs markedly from other renewables, with greater emphasis on operational expenses rather than upfront capital. Feedstock procurement typically represents 30-40% of total costs, making secure, long-term feedstock agreements critical to project viability.

Sacrificial energy consumption—primarily electricity for gas compression and upgrading—constitutes another major expense, driving interest in integrating solar generation or utilising a portion of produced biogas for onsite power. Maintenance and personnel costs round out the operational budget, with most facilities requiring specialised technicians to manage the biological and gas upgrading processes.

Economies of scale significantly impact biomethane economics, with per-unit production costs declining as capacity increases. Industry benchmarks suggest optimal economics at capacities between 500-2,000 Nm³/hour of biomethane, though smaller facilities can achieve viability in niche applications or with premium feedstock arrangements.

Innovative approaches like centralised upgrading serving multiple digestion sites can capture these scale efficiencies while maintaining the distributed benefits of smaller digesters located close to feedstock sources. This hub-and-spoke model represents an emerging trend that optimises both transportation logistics and processing economics.

ROI Timeline Expectations

Return on investment timelines for biomethane grid injection projects typically range from 5-10 years, varying significantly based on regulatory incentives, gas prices, and feedstock costs.

Projects utilising waste streams with associated tipping fees (payment for waste acceptance) generally achieve faster payback than those relying solely on energy value. The most economically attractive projects often combine multiple value streams—energy sales, waste processing fees, carbon credits, and digestate marketing—to enhance overall returns while reducing dependency on any single revenue source.

Industry experience demonstrates that financial performance often improves over time as operators optimize biological processes, reduce downtime, and refine maintenance practices. First-year performance typically achieves 70-80% of design capacity, with gradual improvement reaching 95%+ by year three.

This operational learning curve should be incorporated into financial projections to provide realistic cash flow expectations. With appropriate financing structures that accommodate this ramp-up period, biomethane projects can deliver attractive returns while contributing to renewable energy and waste management objectives.

Available Government Incentives

Government support mechanisms play a crucial role in biomethane project economics, particularly as the industry scales to achieve cost reductions through standardization and experience. Feed-in tariffs, renewable gas certificates, carbon credits, and investment tax incentives create the financial foundation for most current projects. The specific support mechanisms vary significantly between jurisdictions, with European countries generally offering more comprehensive frameworks than other regions. The most effective policies provide long-term certainty (10+ years) that supports investor confidence while incorporating scheduled reductions that drive continuous efficiency improvements.

Beyond direct financial incentives, regulatory frameworks addressing grid access, permitting processes, and digestate utilisation significantly impact project viability. Streamlined permitting procedures and clear technical standards for grid connection reduce development costs and timelines. Similarly, recognition of digestate as a valuable soil amendment rather than a waste product creates additional revenue potential while enhancing environmental benefits. As the biomethane industry matures, policy mechanisms increasingly focus on these non-financial barriers while transitioning financial support toward market-based mechanisms like carbon pricing.

Green Gas Certification Value

Green gas certification schemes provide an increasingly important revenue stream for biomethane producers by verifying environmental attributes that can be sold separately from the physical gas. These programs—including the UK's Green Gas Certification Scheme, Germany's Biogasregister, and various proprietary certification systems—enable consumers to purchase the environmental benefits of biomethane even when connected to different parts of the gas grid. This concept, analogous to renewable electricity certificates, creates premium markets for biomethane while expanding customer access beyond physical pipeline boundaries.

The value of these certificates varies substantially across markets, ranging from minor price premiums to significant multiples of wholesale gas value. Premium pricing typically correlates with certificate features like carbon intensity verification, feedstock sustainability certification, and transparent chain-of-custody tracking. Leading certification systems now incorporate blockchain technology to ensure credible verification while simplifying trading. As corporate sustainability commitments expand beyond electricity to address natural gas consumption, these certification programs create valuable flexibility that accelerates biomethane adoption while optimising system-wide deployment efficiency.

Real-World Success Stories: Biomethane Grid Injection

Successful biomethane grid injection projects demonstrate the practical viability of this renewable gas technology across diverse applications and scales. From agricultural operations converting manure into pipeline-quality gas to municipalities transforming food waste into renewable heat, these implementations provide valuable lessons for future deployments.

Examining these real-world examples reveals both technical and business model innovations that have overcome traditional barriers while delivering multiple benefits to stakeholders and surrounding communities. For instance, biomethane projects in Northern Ireland have shown significant advancements in this field.

Agricultural Waste to Energy Projects

The agricultural sector has embraced biomethane production as a means of diversifying farm income while addressing waste management challenges. In Denmark, a cooperative of 80 farmers operates one of Europe's largest biomethane facilities, processing 800,000 tons of animal manure and crop residues annually to produce 21 million cubic meters of biomethane.

This facility not only reduces methane emissions from traditional manure management but also returns nutrient-rich digestate to member farms, reducing synthetic fertiliser requirements. The cooperative structure distributes both risks and benefits across the farming community while securing the large, stable feedstock supply needed for economic operation.

In the United States, Harmony Biometals in Oregon demonstrates how dairy farms can leverage biomethane to address multiple challenges simultaneously. This installation processes manure from 33,000 dairy cows to produce renewable natural gas that enters the regional pipeline.

Beyond energy production, the project provides crucial benefits in nitrogen management, reducing runoff risks while creating a marketable organic fertiliser product. The project's integrated approach generates revenue from gas sales, carbon credits, and nutrient products—illustrating how biomethane projects can transform environmental liabilities into multifaceted revenue opportunities while supporting sustainable agricultural practices.

Municipal Wastewater Treatment Plants

Wastewater treatment facilities represent natural candidates for biomethane production, as they already process organic material through anaerobic digestion to stabilise biosolids. By adding biogas upgrading equipment, these facilities convert an existing byproduct into valuable renewable energy. In Stockholm, Sweden, the Henriksdal wastewater treatment plant produces enough biomethane to fuel the city's entire bus fleet, creating a closed-loop system where human waste becomes public transportation fuel. This implementation demonstrates exemplary urban metabolism, transforming what was once considered waste into a critical municipal resource.

Thames Water's Didcot facility in the UK showcases how wastewater biomethane can directly displace natural gas in the grid. Processing sewage from 13.8 million customers, this facility produces enough biomethane to heat 5,000 homes continuously. By injecting directly into the national gas grid, the project maximises energy efficiency by avoiding the conversion losses associated with electricity generation. The installation's modularity allows for incremental expansion as upgrading costs decrease, illustrating a phased implementation approach that manages capital risk while capturing growing opportunities in renewable gas markets.

Food Industry Waste Conversion

The food industry generates consistent, energy-rich organic waste streams ideally suited for biomethane production.

In France, a consortium of food processors operates a centralised biomethane facility that processes 58,000 tons of food industry byproducts annually, producing 2.3 million cubic meters of biomethane.

By aggregating waste from multiple sources, the project achieves economies of scale while providing participating companies with sustainable waste management solutions that support their corporate responsibility goals. The facility's strategic location minimises transportation distances while enabling direct grid injection at a major distribution node.

Similarly, Bioenergy DevCo's Maryland Food Center facility demonstrates how food waste from distribution centres and processing facilities can be diverted from landfills to produce pipeline-quality biomethane.

Processing 115,000 tons of food waste annually, this facility generates enough renewable natural gas to heat 4,800 homes while reducing regional greenhouse gas emissions by 26,000 tons of CO₂ equivalent. The project's innovative public-private partnership structure combines municipal waste management objectives with private sector efficiency, creating a replicable model for food waste-to-energy implementations in metropolitan areas throughout North America.

Getting Started: Your Biomethane Project Roadmap

Developing successful biomethane grid injection projects requires methodical planning that addresses technical, economic, and regulatory considerations from concept through commissioning. The journey typically spans 18-36 months from initial assessment to commercial operation, with several critical decision points that significantly impact long-term viability.

This roadmap provides a framework for navigating the development process efficiently while maximising the probability of technical and financial success in this growing renewable energy sector.

Site Assessment and Feasibility Study

The foundation of any successful biomethane project lies in a comprehensive site assessment and feasibility analysis that evaluates both opportunities and constraints. This initial phase should thoroughly characterise feedstock availability, composition, and contractual security within an economical transport radius—typically 15-25 kilometres, depending on feedstock characteristics.

Parallel analysis of grid injection opportunities identifies potential connection points, their capacity limitations, and preliminary discussions with grid operators regarding technical requirements and timelines.

Beyond these fundamentals, initial feasibility studies should assess site-specific factors, including local planning policy (zoning) compatibility, environmental sensitivities, and community context.

Early engagement with local stakeholders often identifies potential synergies or concerns that can be addressed proactively in project design. The most successful projects incorporate this stakeholder input early, adapting configurations to maximise local benefits while mitigating potential impacts.

Financial modelling during this phase should emphasise sensitivity analysis rather than precise forecasting, identifying which variables most significantly impact project viability. This approach highlights critical success factors requiring focused attention during development while establishing realistic performance parameters for go/no-go decisions.

Leading developers maintain flexibility during this phase, evaluating multiple configurations and scales to identify optimal arrangements before committing significant capital to detailed design and permitting.

Technology Selection Guidelines

Selecting appropriate technology represents a pivotal decision that balances capital costs, operational requirements, and performance guarantees. The digestion technology must align with feedstock characteristics—CSTR (Continuously Stirred Tank Reactor) systems for liquid wastes, dry fermentation for high-solids streams, and multi-stage systems for rapidly degradable materials like food waste.

Similarly, biogas upgrading technology selection depends on scale, electricity costs, and whether CO₂ recovery offers additional value. These selections should prioritise proven technologies with reference installations processing similar feedstocks, particularly for projects without extensive in-house operational expertise.

Beyond core process technology, careful attention to automation, monitoring, and control systems significantly impacts operational efficiency and maintenance requirements.

Constant monitoring of the FOS/TAC ratio combined with intelligent dosing systems can significantly improve both gas yield and quality consistency while reducing operator intervention, particularly valuable for facilities in areas with limited access to specialised technical support.

Regulatory Approval Process

Navigating the regulatory landscape represents one of the most time-consuming aspects of biomethane project development, typically requiring 9-24 months for full approval in the UK. The process generally includes planning permission, environmental permits, grid connection agreements, UK green gas subsidy application, and renewable incentive qualification.

Successful developers adopt a parallel processing approach where possible, advancing multiple permit applications simultaneously while identifying critical path items that require expedited attention. Early consultation with regulatory authorities often reveals jurisdiction-specific priorities that can be proactively addressed in project design, potentially streamlining the approval process.

The grid connection process deserves particular attention, as it often involves multiple stakeholders with different timelines and requirements. Formal grid connection applications should be submitted early in the development process, with regular follow-up to ensure timely processing.

The specific technical requirements for grid injection—including gas quality parameters, pressure requirements, and monitoring protocols—should be formally documented in a connection agreement that clearly delineates responsibilities between the biomethane producer and grid operator. This formal agreement provides essential certainty for both technical design and financial planning.

Installation and Commissioning Timeline

With approvals secured and technology selected, the installation phase typically requires 8-12 months from groundbreaking to initial gas injection. This timeline assumes thorough front-end engineering and design (FEED) that resolves integration details before major equipment arrives on site. The critical path usually includes digester construction and curing, which requires minimum concrete curing times that cannot be compressed regardless of other schedule pressures. Parallel installation of gas upgrading equipment, grid connection infrastructure, and balance-of-plant systems maximises efficiency during this phase.

Commissioning represents a critical transition requiring methodical progression from individual component testing to integrated system operation. The biological startup deserves particular attention, as establishing robust microbial communities typically requires 2-3 months of carefully managed feeding rates and environmental conditions. The most successful projects implement detailed commissioning plans with clear performance criteria for each subsystem, gradually increasing throughput as operational stability is demonstrated. This measured approach minimises both technical risks and startup delays while establishing the operational baseline that will support long-term performance optimisation.

Future of Green Gas: What's Next for Biomethane

The future of biomethane looks increasingly bright as technical innovations, policy support, and market demand converge to accelerate the deployment of this versatile renewable gas.

Emerging technologies like power-to-gas hydrogen integration, advanced carbon capture, and biochar co-production promise to further enhance both economic and environmental performance. These innovations build on biomethane's already compelling benefits—greenhouse gas reduction, waste management, and energy security—positioning it as an essential component in decarbonising challenging sectors like industrial heating, heavy transportation, and seasonal energy storage.

Industry consolidation and standardisation represent another important trend, with larger developers implementing modular, replicable designs that reduce costs through economies of scale and streamlined engineering. This industrialisation of what was once a highly customised sector mirrors the evolution of solar and wind energy, suggesting similar potential for rapid cost reduction and deployment acceleration.

As the biomethane industry matures, increasing integration with broader renewable energy systems—particularly through dynamic grid balancing and seasonal storage applications—will likely enhance its value proposition beyond simple natural gas replacement, creating new opportunities for innovative business models and expanded market applications.

Frequently Asked Questions

As biomethane grid injection gains prominence in renewable energy discussions, several common questions arise from potential developers, policymakers, and energy consumers. These frequently asked questions address the fundamental technical, economic, and environmental aspects of biomethane production and utilisation, providing essential context for stakeholders evaluating this renewable gas option.

How does biomethane compare to natural gas in terms of energy content?

Upgraded biomethane contains approximately 36-40 MJ/m³ of energy, effectively identical to conventional natural gas, which typically ranges from 37-41 MJ/m³ depending on source. This equivalence enables direct substitution without requiring modifications to end-use equipment or appliances.

The methane molecule (CH₄) itself is chemically identical whether derived from fossil or biological sources; the key difference lies in the carbon cycle impact rather than combustion properties. When properly upgraded to grid standards, consumers cannot detect any difference in performance between biomethane and conventional natural gas in heating, cooking, or industrial applications.

What types of organic waste can be used to produce biomethane?

Virtually any biodegradable organic material can potentially produce biomethane, though economic viability varies significantly with feedstock characteristics. Common feedstocks include animal manures, food processing byproducts, municipal food waste, sewage sludge, agricultural crop residues, and dedicated energy crops.

Each material offers different biogas yields, digestion characteristics, and nutrient profiles that influence both technical design and economic performance. Many commercial facilities process multiple feedstocks simultaneously—a practice called co-digestion—to optimise both gas production and digester stability while providing year-round operation despite seasonal availability of some materials.

How long does it take to build and commission a biomethane grid injection facility?

A typical biomethane grid injection facility requires 18-36 months from initial concept to commercial operation, with construction and commissioning representing approximately 10-14 months of this timeline.

The development period varies significantly based on project complexity, regulatory requirements, and grid connection procedures specific to each jurisdiction. Key factors affecting the timeline include feedstock complexity (which influences digester design), upgrading technology selection, and the proximity and capacity of suitable grid connection points.

Projects integrated with existing infrastructure, like wastewater treatment plants or agricultural digesters, can often achieve faster implementation by leveraging existing permits and infrastructure.

What percentage of natural gas can biomethane realistically replace in our current infrastructure?

Biomethane's potential contribution to natural gas supply varies significantly between regions based on organic waste availability, natural gas consumption patterns, and land use considerations.

Technical assessments suggest biomethane could realistically replace 10-30% of current natural gas consumption in most developed economies without requiring significant land use changes or competing with food production. Higher percentages are achievable in agricultural regions with substantial organic waste resources and relatively low population density.

When combined with efficiency improvements and electrification of appropriate end uses, biomethane can play a crucial role in decarbonising the most challenging applications where gas provides unique benefits like high-temperature heat, seasonal energy storage, or chemical feedstocks.

Are there any safety concerns specific to biomethane grid injection?

Biomethane grid injection utilises the same safety standards and protocols as conventional natural gas, with additional quality monitoring specific to biological production. Modern grid injection facilities incorporate multiple safety systems, including continuous gas composition analysis, automatic shutdown valves, leak detection, and over/under pressure protection.

The primary safety focus involves preventing off-specification gas from entering the distribution system, which is addressed through real-time monitoring and automatic diversion systems. Proper odorization ensures leak detectability by adding the same odorants used in conventional natural gas. With these measures in place, biomethane has demonstrated an exemplary safety record comparable to or better than conventional natural gas operations.

The transition to renewable energy continues to accelerate worldwide, with sustainable solutions like biomethane playing an increasingly crucial role. As highlighted by the World Biogas Association, green gas represents a vital component in our energy future that delivers both reliable power and significant greenhouse gas reductions. The technology continues to mature, with new innovations constantly improving both economic and environmental performance.

Contact the World Biogas Association today to learn more about how green gas can support your organisation's sustainability goals while contributing to global climate solutions.

[Article originally published December 2021.]